The E.C.C.

When the new Corporation was formed, it purchased and

amalgamated the following companies and their patents:

1). Elwell-Parker, Limited. Employing 400

people with a large order-book.

2). The Elecrical Power Storage Company Limited, and their Millwall

factory, together with the company's many electrical power storage

patents.

3). The Railway Electrical Contractors Limited, and their patents

and contracts for train lighting.

4). The Julien Patents for Electric Traction, the Sprague Patents

for Electrical Traction and the Transmission of Power.

The starting Capital of the Corporation was £500,000

in 50,000 shares of £10 each. Numbers 1 to 100 inclusive were Founder’s

Shares. The new concern was incorporated on 7th June, 1889,

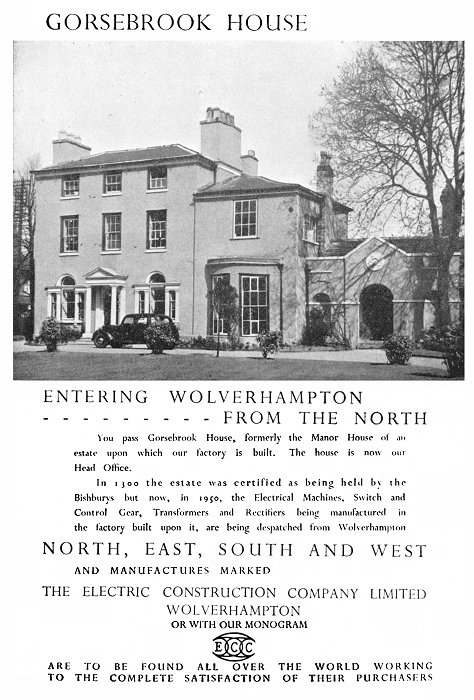

and it was decided to build a new works on the land already purchased by

Elwell-Parker at Bushbury, along with some adjacent land. The new works

were erected at a cost of £10,000 on the 24.5 acre site. When the

building work was complete, the staff and machinery from Commercial Road

were moved to the new site.

The directors included:

Sir Henry C.

Mance, C.I.E. (Director of the West African Telegraph Company)

Sir Daniel Cooper,

Bart., C.M.G. (Chairman of the Electric Power Storage Company Ltd.)

Mr. John Irving

Courtenay (Managing Director of the Electric Power Storage Company Ltd.)

Sir Douglas Fox

(Member of the Council of the Institution of Civil Engineers)

Sir James Pender,

Bart., K.G. (Director of the Eastern and South African Telegraph

Company)

George Dibley

(Director of Andrew Handyside & Company Limited)

Sir Robert Fowler,

Bart., M.P. (Director of the Metropolitan Electric Supply Ltd.)

Henry P. Holt

(Crossley Brothers Ltd, Manchester. Director of Elwell-Parker Ltd.)

Joseph Moseley

(David Moseley & Sons, Manchester. Chairman of Elwell-Parker Ltd.)

John B. Verity

(Director of the Metropolitan Electric Supply Ltd.)

Thomas Parker was Works Manager and the engineer was J.E.H. Gordon, who

was well known for his work on connection with the early electric

lighting at Paddington Station.

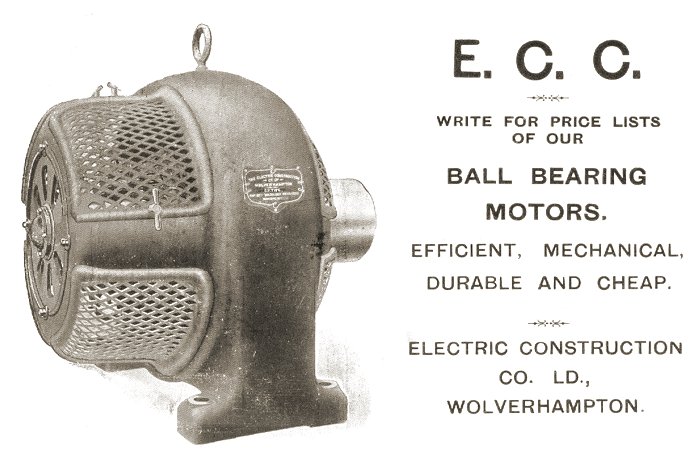

The company produced almost every conceivable piece of electrical

equipment. Some of the company’s products were alternators, dynamos,

motors, accumulators, ammeters, voltmeters, duplex dynamos,

transformers, resistance frames, magnetic transformer switches,

switchgear, knife switches, continuous current rotary transformers,

battery charging transformers, electrical switchboards, high voltage

switches, voltmeter switches, arc lamps, and gas tight motors for

electric pumps and electric cranes. The company also produced a 52

passenger tramcar for the Bournemouth Tram Depot, a 9h.p. narrow-gauge

electric locomotive, an alternator for Manchester Square Station, a 34

passenger accumulator tram for Birmingham Tramways, 15h.p. tramcar

motors for the South Staffs Tram Co. and electric colliery locomotives.

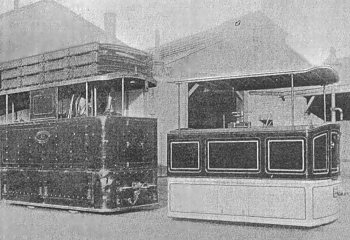

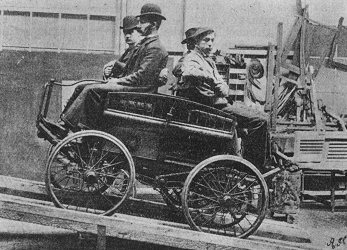

| In 1888 Elwell-Parker, Limited developed an

electrically powered tram for the Birmingham tramways. Due to its

success, E.C.C. got the order to install an electric accumulator

tramway in the city. |

An E.C.C. electrical accumulator locomotive |

The Corporation got off to an excellent start under the chairmanship of

Sir Henry Mance. The works were operating at full capacity and orders

flooded in, including a further order from the Birmingham tramways,

following the successful running of the Elwell-Parker prototype. In the

battery-powered vehicles, the accumulators were placed under the

passenger's seats, and a portion of the gross profit was absorbed in the

settlement of claims from passengers, whose clothing had been splashed

by acid.

In 1890 the company carried out the electrification of Sir Daniel

Cooper's Tudor Mansion, Grim's Dyke. Two E.C.C. 26 seater omnibuses were

running in London in 1891. They ran from Charing Cross to Victoria

Station and were powered by two large electric motors, and 72 lead-acid

batteries. They had wooden wheels with iron tyres. The company also

built a number of battery powered, 14 seater, single decker buses, for

the London Electric Omnibus Company.

|

The company's most famous

motor car was the Electric Dog Cart, which was built in 1896. |

Within four years the new company found itself in deep trouble and was

voluntarily wound up in July, 1893. It seems that there was a lot of

dissension amongst the Board of Directors, one of whom later was

convicted of fraud. The company was reconstructed as the Electric

Construction Company Limited. Sir Daniel Cooper was Chairman and Mr.

P.E. Beachcroft, J.W. Barclay and J. Irvine Courtenay joined the Board.

The Company Secretary was Mr. James Gray and Mr. Emile Garcke joined the

Board to be responsible for the reconstruction of the commercial side of

the business.

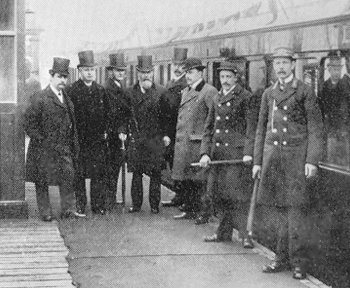

| The company produced an overhead wire system for the

electrification of the South Staffordshire Tramways and a little

while later installed a similar system at Hartlepool. The company

also carried out the electrification of the Liverpool Overhead

Railway, which was opened by the Marquis of Salisbury on 4th

February 1893.

In 1894 Thomas Parker left to start his own company. He was replaced as

Works Manager at Bushbury, by Mr. A.B. Blackburn. |

The opening ceremony of the Liverpool

Overhead Railway. Thomas Parker is on the extreme left. |

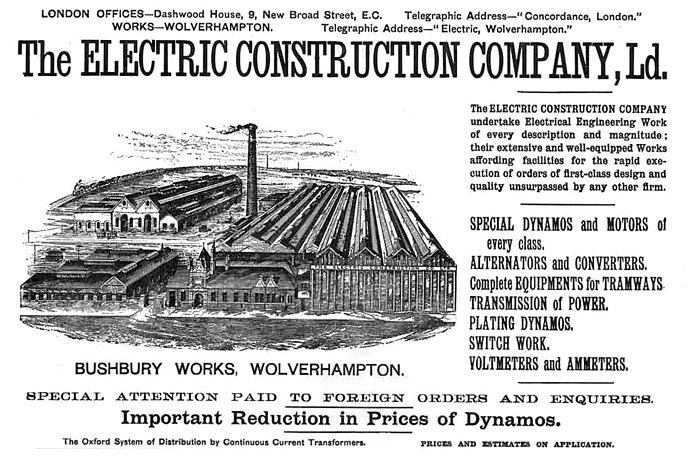

|

An advert from 1893 listing some of the

company's more important installations.

|

The E.C.C. installed a number of electricity supply stations that were

based on a high voltage D.C. system. The central generating station

produced the high voltage, which was converted to 200 volts D.C. by

motor-generators, which were housed in sub-stations. The first

installation was at Oxford and used a 2,000 volt high tension line. This

became known as the Oxford System. Following its success, similar

systems were installed at Wolverhampton, Birmingham, Charing Cross,

Chelsea, Sydenham and Shoreditch.

The company also built the switchgear for the Burnley Electric Light

Station, the third rail tramway system for the Portrush and Giants

Causeway Tramway Company and tramways in Brussels and Melbourne.

|

The

Crystal Palace Electrical Exhibition. The Engineer, 1st

April, 1892.

The present exhibition at the Crystal

Palace will mark the successful operation of one of the most

practical modern schemes for the distribution of electric

current over wide areas. The continuous current transformer

has here asserted itself, and proved that with carefully

worked out details in construction, and in the system with

which it is

used, it is a most trustworthy and

efficient means of securing the advantages of a high tension

distribution with a continuous current supply. No

undertakers who find themselves called upon to extend their

low tension mains into remote suburban districts need fear

that because they do not happen to be using alternating

currents, they must either bear the cost of additional

stations to feed the network or sink excessive amounts in

mains.

The entire system has been worked out

on a practical basis by the Electric Construction

Corporation of Wolverhampton under the guidance of Mr.

Thomas Parker, the works director, and one of the most

pleasing exhibits in the exhibition is to be found in the

stand of this Corporation in the Machinery Court, containing

as it does machines of such high-class construction, and

controlling apparatus so well suited to the requirements of

the system.

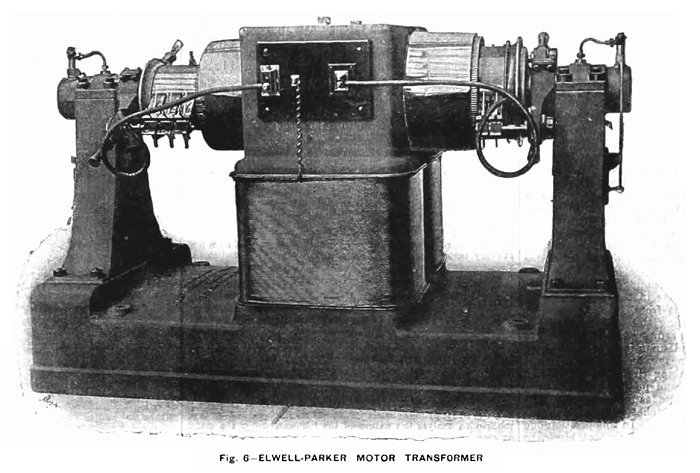

The largest machine in this stand, Fig.

6, is a continuous current transformer or motor transformer,

identical in size and output with the ten machines used

inside the Palace for the supply of current to exhibitors.

It is to be regretted that it was found necessary to fix

these machines so far out of sight underneath the Palace, as

otherwise their full display in operation would have

considerably added to the practical interest of the

exhibition.

We have already explained the working

of the machines in the Palace, which receive current at

1,000 volts pressure from the Crystal Palace and District

Electric Supply Company’s Station at Sydenham, one and a

quarter miles distant, and transform it down to a pressure

of 110 volts for exhibitors. The complete system of

distribution by these motor transformers for town lighting,

as now adopted at Oxford, will be understood by reference to

Fig. 7.

In the first place there is the

generating station, the site of which is selected with

reference to good water supply and economical facilities for

delivery of coal. In this station are installed the

necessary engines and boilers, together with the electric

generators and their exciters. As the area of lighting

extends, more generators can be added, their manipulations

in parallel being perfectly simple. These produce current at

1,000 volts pressure, which is delivered by all the machines

on to one pair of bars in the station, known as omnibus

bars, or shorter, bus bars. From these the current proceeds

along the high tension mains to the most central point in

the district of supply, at which is located a central switch

station.

From this station is controlled the

working of all the transformers used in the system, these

machines being located in sub-stations situated radially

around the switch station at points most favourable for

feeding the low tension network of supply, and keeping the

electric pressure uniform throughout. At the switch station

there is a pair of omnibus bars receiving the high tension

current from the generating station, and from which the same

current is, through double pole switches, connected onto the

feeders supplying the motor transformers at the

sub-stations. For the complete control of all the

transformers only one man is required in the switch station.

The voltmeters in this station show the

pressure on the town supply network at all the sub-stations,

and as the load increases in any district, the pressure is

kept up by switching on an additional transformer located in

that district. Although the sub-stations where the

transformers are fixed are at various distances away from

the switch station, the switching in or out of these

machines controlled by one man at the above station with

perfect certainty and ease.

In performing this operation the first

thing to do is to close the two-pole switch which conveys

the high-tension current to the transformer. The current,

which passes through a considerable resistance before

leaving the station, passes into the armature of the machine

on the high-tension side, and excites the field through a

few turns of thick wire in series. The brushes on both

commutators are kept permanently down, and need no

alteration of lead for changes of load, as the reactions of

the two armatures neutralise one another. Once the

excitation of field is started, the machine starts, at first

quickly, but the shunt field rapidly building up, the speed

soon decreases again, and is then brought up to the required

amount by reducing the main resistance in the switch

station. So far the transformer is started, but the

secondary winding on the armature is not yet put in

connection to feed the supply mains. This is done at the

switch station by the simple act of momentarily closing and

opening a switch which short-circuits the voltmeter. This

causes a current to flow through an automatic circuit closer

fixed with each transformer in the sub-station.

This apparatus, shown in the figure,

consists primarily of an iron-clad electromagnet, the

exciting coil of which is included in the circuit of the

voltmeter at the switch station. The resistance being small

does not interfere with the voltmeter readings, and,

moreover, by short circuiting the voltmeter in the switch

station for an instant, a large current from the supply

mains flows through the coil, causing the armature of the

magnet to be drawn up. The armature carries two pawls lying

on a ratchet wheel, and upon its being attracted upwards,

the left-hand pawl engages one tooth and moves the ratchet.

Again, on breaking the short-circuit

the armature falls, and the right-hand pawl engages, forcing

the wheel round further in the same direction. The double

operation moves the ratchet wheel and cam through one-eighth

of a revolution. In this position one tooth of the cam bears

down on the contact block, so completing the low tension

circuit from the transformer to the mains. The load on the

mains is equally divided between the transformers at work,

but in case of short circuit or any accidental stoppage

which would cause an undue rush of current into the machine,

an automatic cut-out, shown at M is fixed in connection with

the above apparatus. The armature of the electromagnet M

would in such an event be drawn up and strike the cam,

shifting it round and disengaging the tooth from the contact

piece S, thus breaking the circuit.

Similarly, as the load decreases, the

various transformers can be severally disconnected from the

supply by the operator at the switching station. Once

closing and opening the voltmeter switch shifts the cam

another eighth round, and allows the contact piece S to rise

and break circuit.

|

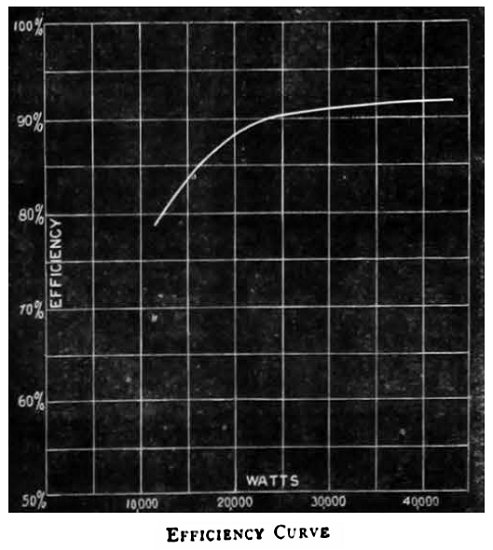

By this arrangement the transformers are only

used as the load requires, and are therefore, for

the greater part of the working time, near their

full load; and as the efficiency of these machines

reaches 92 percent when delivering their full load

of 40 kilowatts, and 87 percent at half load, see

curve, Fig. 8, it will be seen that the whole system

is worked with great economy. The only regulation

required in the generating station is the adjustment

of the strength of exciting current supplied to the

generators, the pressure, as indicated by a

voltmeter on the omnibus bars in the station, being

maintained constant by this means. The exciting

current is regulated by resistance in the shunt

field of the excitors, of which there is a separate

machine for each generator. |

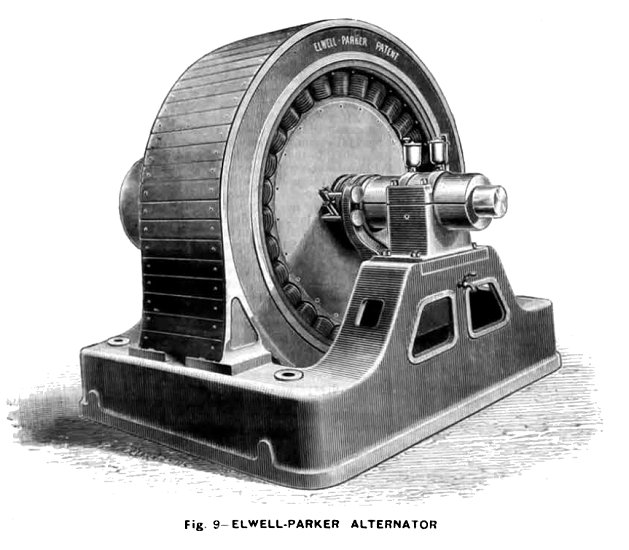

The Corporation have also carried out

several important contracts in alternating current plant. We

illustrate the Elwell -Parker alternator, Fig. 9, of 80

kilowatts, as exhibited in operation at the Palace. The

armature is a stationary external ring, built up of soft

iron rings, to the inside surface of which are clamped the

coils. The latter are twelve in number and composed of

copper strip, the edges being placed radial to the machine.

These are held by wooden clamps bolted round the ring on

each side. The field magnet, with the same number of coils,

mounted on cores and yoke of solid forged iron, rotates

inside the armature. The machine being high-tension, the

armature is externally cased-in with a wooden cover, and the

terminals of the machine are protected under a portion of

this cover, kept under lock and key. The wires leading from

these terminals are also taken underneath the bed of the

machine in casing through the concrete, so that complete

immunity from danger is attained.

Alternate current transformers of 2 and

4 horse power output are also shown in Fig. 10. These are of

very simple construction, the two circuits being first bound

together and afterwards encased around with soft iron plates

made in the form of the letter L and built up on each side

of the coils. The two rows of discs are then clamped

together by bolts passing through cast iron end pieces.

The Corporation also exhibit a new

pattern of adjustable resistance, sets of cut-outs fitted in

porcelain boxes, and a high tension automatic switch used in

connection with the above transformers. |

|

|

Electric Lighting in Oxford. The

Engineer, 1st July, 1892.

On Saturday, June 18th, the electric

current was switched on for the first time to the City of

Oxford, by the Oxford Electric Company, and a large party

had been invited to a dinner given at the works in honour of

the occasion. The arrangements were very satisfactorily made

by Mr. George Offor, the secretary of the company. We have

referred previously in our issue of April 1st last to some

of the features of the system employed, and are now able to

give a full description of the plant.

It was found impossible to obtain a

suitable piece of ground for the works near the centre of

the city, a piece of land was therefore acquired at Osney

upon the banks of the River Isis.

The outside of the building, which are

of a neat design in brick, is shown in Fig. 1. The interior

of the engine room is shown in Fig. 2, from which it is

evident that there is ample room for more plant. This

position will enable the company to charge electric

launches, which will be an important source of revenue, and

the works are kept away from the better parts the town.

The

system adopted is that of high-tension continuous currents,

with dynamotors or current transformers, which produce

currents of low pressure for the network. The dynamos at the

generating station produce the current at a pressure of

1,000 volts, and this is transformed down at the sub

stations to a pressure of 100 volts. Fig. 3 is a plan of the

part of the city in which the substations are placed, and

the mains already laid along the streets are shown.

The

contractors for the whole work are the Electric Construction

Corporation, of Wolverhampton, and it has been carried out

under the supervision of Mr. Thomas Parker, the managing

director. The building is a well built structure of brick,

designed by Mr. Brevitt, of Wolverhampton, and the builders

were Messrs. Kingerley, of Oxford.

It is divided into two main sheds,

separated by a brick wall. The engines and dynamos are

placed in one part, and the boilers in the other, and all

the plant is on the ground level. The engine room is thus

kept perfectly free from coal dust. Three steel boilers of

the locomotive type are at present installed; these were all

built by Messrs. J. and H. McLaren, of Leeds; a Green's fuel

economiser is placed in the main flue and a suitable by pass

is arranged so that gases may pass direct to the chimney if

needful.

The engine room is well lighted from

above. The steam pipes are arranged upon the ring system, so

that in case of breakdown, as little as possible of the

plant would be affected. Stop valves are placed between each

two engines, and the bends are all of copper. Three engines

are now put down, and these are of the inverted

triple-expansion type, built by Messrs. J. and H. McLaron

and Co. By the courtesy of the makers we are enabled to give

the results of tests which were carried out at the works by

Mr. Wilson Hartnell, Professor Goodman, and the inspecting

engineer, Mr. Watson. The sizes of the cylinders are:-

high-pressure, 9in. diameter, intermediate, 14·25in.,

low-pressure 22·5in. diameter, by 24in. stroke.

Two trials

were made, in one of which it will be observed the steam

jackets were used, an in the other were not used. We may add

that the high-pressure and intermediate cylinders are jacketted with steam at boiler pressure, and are drained

through a McDougal steam trap into the hot well. The

low-pressure cylinder is not jacketted. The McLaren

automatic governor is placed inside the fly-wheel upon the

shaft itself, and it works direct on to the high-pressure

slide valve, which is not balanced in any way. The governor

is self-locking, and is therefore not affected by any

friction on the slide valve. The engines run very steadily,

and all danger of the governor being put out of gear by the

breaking of a belt is obviated. The surface condenser

is fitted with brass tubes and tube plate; the tubes are

⅞in. outside diameter, and there is 382 square feet of

cooling surface.

The air pump is 11½in. diameter, the

circulating pump 10in. diameter, and the feed pump 1¾in.

diameter, all three having a stroke of 14in. The pumps are placed behind the

condenser, and are worked by levers from the intermediate

engine. The crank shaft is of forged steel, 5¼in. diameter,

the crank pins 5½in. diameter, and the engines are

thoroughly well finished. Each of the engines is provided

with a heavy fly-wheel, and drives a dynamo by means of

belting; two of the belts are of the usual double-sewn type,

and the third is a Gaskin link belt.

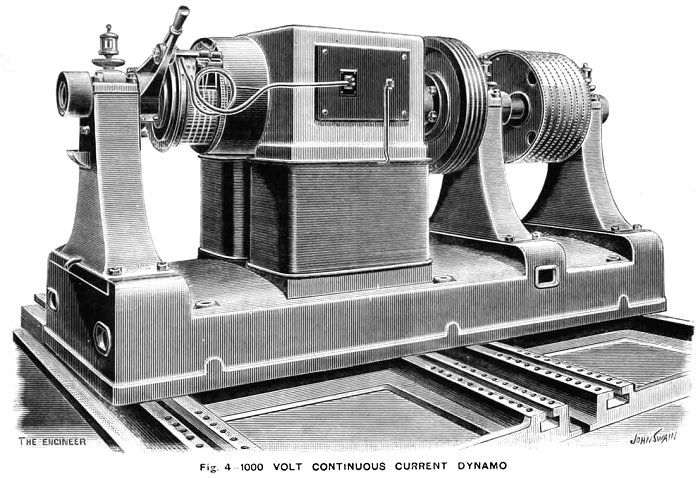

The three dynamos, one of which is

shown in Fig. 4 are all similar, and were built by the

Electric Construction Corporation; each develops 1,080 volts

and 80 amperes, when running at 400 revolutions per minute.

The dynamos are provided with an extra bearing outside the

driving pulley, and each is excited by a small Elwell-Parker

dynamo, driven from a rope pulley keyed on to the shaft of

the main generator. The exciters give 135 volts, and can

thus be used to charge the accumulators which are used for

lighting the central station.

The electro-motive force of the dynamos

can be regulated from 1,100 volts at full load to 1,000

volts at light load, by means of resistances placed in

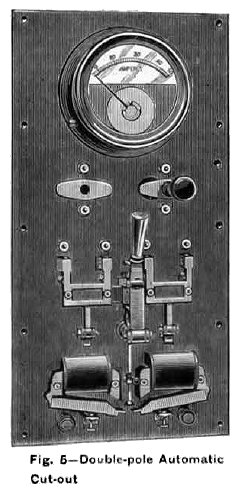

circuit with the exciters. In the circuit of each dynamo is placed

a double pole automatic cut-out, shown in Fig. 5 which

protects the dynamo in the event of any excessive current,

and is reset by hand, but it is so arranged that the cut-out

cannot be held on. The dynamos are all connected in parallel

to two common omnibus bars upon a switchboard at the works.

The foundations for the engines are of

a solid block of concrete, and that for the dynamos another

solid block, weighing about 100 tons each, and about 11ft.

deep. Air spaces are left round the blocks to diminish

vibration.

The switchboard at the works is very

simple, and consists of three panels, each of which is

similar to Fig. 5, and carries one ammeter for the high

tension circuit, one for the exciter circuit and the

knocking-off switch previously alluded to.

|

Two overhead cranes, each capable of

lifting six tons, are provided in the engine house, and a

battery of fifty three E.P.S. cells is used for the lighting

of the station. By means of this battery and of that at the

chief sub-station, it is possible to shut down altogether at

the works for six to eight hours in winter, and twelve to

sixteen hours in summer. At the time of our visit, Mr.

McLean, the engineer in charge, had placed a dynamotor in

the works in order to light up about five arc lamps of

fifteen amperes each, and 370 eight candle-power lamps.

Current was also supplied for the electric cooking, which

formed a feature of the dinner.

From the generating station run out two

pairs of heavily insulated Silvertown cables, each

consisting of 37/14 copper wires; these are laid in

cast iron pipes, and are carried a distance of about

one mile to the distributing station at Broad Street

marked No.1 on the plan, Fig. 3.

The system of working is clearly shown in

diagram-Fig. 6 which we published in a previous

issue. It will be seen that the dynamos are coupled

to two omnibus bars at the generating station, and

thence run the high-tension mains to the central

switch station, whence all the other sub-stations

are controlled. |

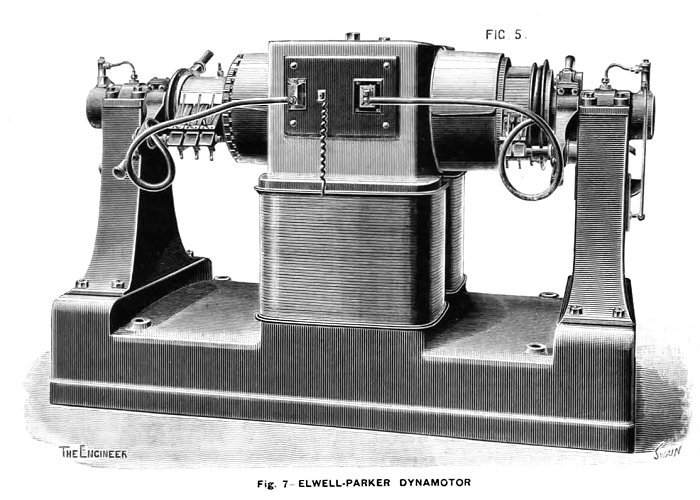

At each of the

stations, Nos. 1, 2, and 3 on the plan Fig. 3, is placed a

dynamotor, such as shown in Fig. 7, which transforms the

pressure from 1,000 volts to 110 volts, and gives out a

current of 360 amperes when fully loaded. The efficiency of

these machines is very high, being 92 percent when fully

loaded, 89 percent at three quarters load, and 87 percent at

half load. The main winding is a shunt to the low-tension

side, and there are a few turns on the magnets in series

with the high-tension armature. The oiling arrangements are

very complete. The end of the armature shaft is provided

with a cam, which actuates the piston of a small oil pump

which feeds the bearing; the oil passes away through a

filter to the oil reservoir, and is used over again. It is

thus possible to run for some days without attention. The

brushes upon the commutator are of copper gauze.

An accumulator of 114 cells of the L.

31 E.P.S. type is installed here, and the cells are arranged

in four groups, two of thirty-eight cells and two of

nineteen cells. They are charged in three groups of

thirty-eight cells each, and are discharged in two groups,

each consisting of thirty-eight and nineteen cells in

series, and are capable of supplying a current of 120

amperes for eight hours.

|

Voltmeters are provided at the central

switch station, which show the pressure at each of the

sub-stations, and all the transformers can be controlled by

one man. In starting a transformer the high-tension circuit

is first closed through a resistance in order not to injure

the armature windings.

The dynamo field is then excited by a

few coils in series. The dynamo part then begins to produce

current, and the resistance is gradually taken out of the

high-tension circuit.

In order to put the transformer into

circuit with the low pressure network, a special apparatus

has been designed, shown in the diagram and also in Fig. 8;

this instrument is placed at the sub-station and is designed

for 400 amperes.

It consists of a long-pull electro-magnet,

which actuates a ratchet wheel and controls the switch. It

is actuated by merely closing and opening a switch which

short circuits the voltmeter on the pilot wire. One of the

wires to the voltmeter is wound round the long-pull magnet,

and the feeble current passing to the voltmeter under

ordinary conditions is not sufficient to attract the

armature, but by closing the switch the voltmeter is cut out

of the circuit, and the long-pull magnet acts; the switch is

then opened, the heavy armature drops, and the double

movement causes the switch which connects the low-tension

network to the transformer to close. In cases of accidental

overloading, an automatic cut out-shown in Fig. 5 opens the

circuit.

|

|

The present capacity of the entire

plant is 12,000 lamps of 32 watts, and 15,000 lamps could be

wired. The low-tension mains were manufactured and laid by

Callender's Bitumen Telegraph Company, under the

superintendence of their engineer, Mr. W. Douglas Reid.

Those cables are of two sizes, half a square inch and a

quarter of a square inch section, and are of the

lead-sheathed type, armoured with two layers of steel tape.

These cables are simply laid in a trench under the footway,

at a depth of about 18in. They are laid in lengths of from

150 to 200 yards, and are connected together in cast iron

joint-boxes by means of copper connectors. The box is then

run in solid with bitumenised wax compound. Disconnecting

branch boxes are provided at different points in the network, so

that any section or street can be cut out without in any way

interrupting the supply to the rest of the network.

House service wires are connected in T

boxes by means of T copper connectors. These boxes and

connectors are so made that the cable is not out, but is

simply bared down to the copper strands and the connector

put on and soldered. The box is then run in solid with the

bitumenised wax compound. The small service wires are of two

sizes, seven fourteenths and twelve fourteenths, lead

sheathed and armoured. The arc cables are similar, but seven

sixteenths. The whole installation is a very interesting

example of the possibility of using high-tension continuous

currents for large areas.

|

|

High Tension Continuous Current Switchgear. The Electric

Construction Corporation, Wolverhampton. The Engineer 31st

March, 1893. |

|

The switchgear illustrated by the

accompanying engravings are those used by the Electric

Construction Corporation, Wolverhampton, for their high

tension continuous supply system, as used at Oxford, and at

Sydenham.

The system consists in supplying a

system of distributing mains with current from a number of

motor generators situated at sub-stations, these being

supplied with current by high tension feeders run directly

from switchboards at a central station. Each transformer has

a separate feeder, and a pair of pilot wires also come back

from each sub-station. The starting, stopping, and

controlling of the motor generators is carried out from the

central station.

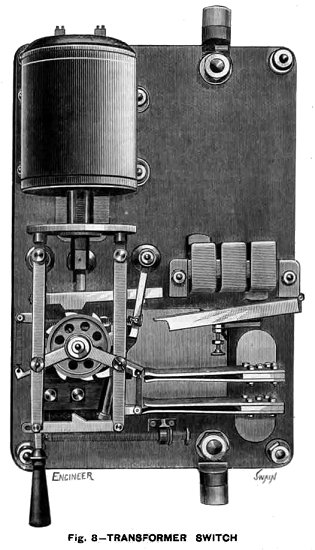

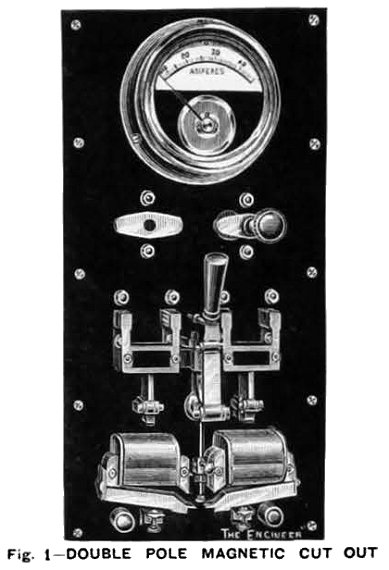

Fig. 1 represents a double-pole

automatic magnetic cut-out and main switch, which is coupled

on to the main omnibus bars at the central station, and from

which feeders running between the transformers are

connected.

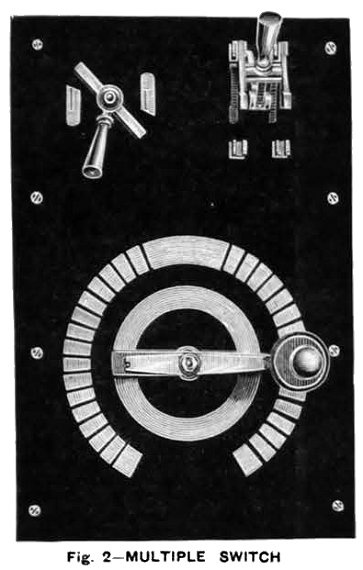

Fig. 2 represents a multiple contact

switch for cutting resistance in or out of the high-tension

feeder circuit. To start a transformer the multiple-contact

switch - Fig. 2 - is turned over, so that all resistance is

in circuit. The automatic cut-out- Fig. 1 - is then put on

so that the high tension current passes to the motor

generator at the sub-station. |

|

|

A few turns of thick wire wound round

the magnets in series with the feeders gives the necessary

magnetic field, enabling the motor generator to start. The

secondary or low tension then gradually magnetises the motor

generator field up to its full strength by a shunt across

the low-tension armature.

The starting resistance, which is

connected to the right-hand side blocks of the multiple

contact switch, Fig. 2 - is then taken out of circuit. The

small quick-break switch, shown at the top left hand corner

-Fig. 2 - is then closed, which short circuits the pilot

wires running back from sub-station, and one of these, wound

round a pot magnet, actuates a special transformer switch,

which connects the low-tension armature of the motor

generator on to the distributing mains. This switch is then

again broken, as only a momentary current is necessary, the

switch being held in either an on or off position by

springs.

A voltmeter is connected across the

pilot wires so as to indicate the electro-motive force on

the network at the feeding point. The regulation of this

electro-motive force is carried out by the left-hand blocks

of the multiple-contact switch - Fig. 2 - cutting resistance

in or out of the circuit. |

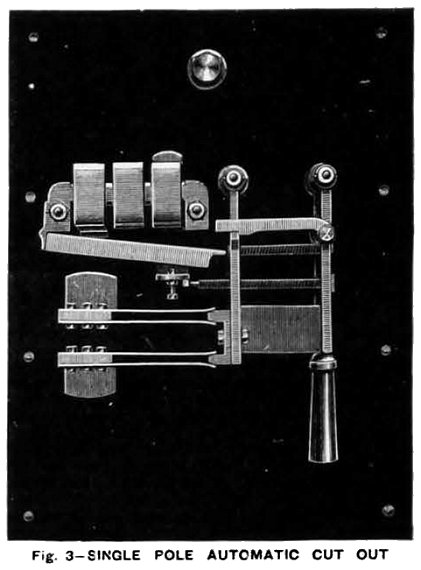

| Fig. 3 represents a single-pole automatic magnetic

cut-out, as is used at Oxford on the low tension of

transformers, situated at the central station, where they

can be reset by hand.

These cut-outs break circuit in event of an excessive

current being demanded by a short circuit on the mains.

The magnet is compound-wound, so that in the event of one

of the motor generators failing to give proper

electro-motive force, the current passing back from the

mains cuts out at a much smaller number of amperes, so as

not to cause an excessive demand from any other motor

generators that may be on the circuit, which is a thing that

always happens where ordinary fuses are employed; any fault

due to one machine failing to give its electro-motive force

usually melting the fuses of other machines that may be

connected in parallel on to the same circuit, owing to the

large current required to cut out the machine that has

failed. |

|

|

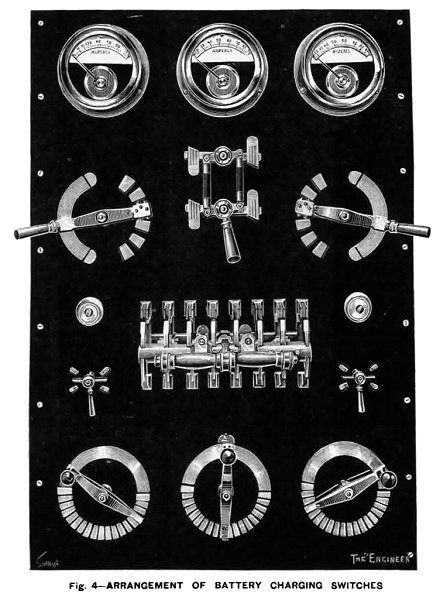

Fig. 4 represents an arrangement for charging a battery

of accumulators from distributing mains. As these are kept

at a constant electro-motive force, it is necessary to

cut-up the battery into sections for charging. At Oxford

there are 120 cells. These are charge in sets of 40 each,

discharging in sets of 60 each. A throw-over switch in the

centre of the board enables this alteration to be effected.

Three multiple contact switches at the bottom of the board,

and three ammeters at the top, are connected, one in each of

the three series when charging.

Two multiple contact switches enable the number of cells

in the discharging circuit to be regulated, and a

double-pole switch is provided for cutting off the

accumulators entirely. The two-way switches are provided for

connecting the voltmeter across one or other of the

batteries. |

|

In1895 the E.C.C. completed an order for the switchboard and

transformers for St. Panchras Station, engines, exciter and switchboards

for the Oxford Electric Light Station. In the same year the company

built and installed the switchboards, switchgear and generators for the

Wolverhampton Generating Station, and generating plant for Oxford

Central Station. The company also installed electric lighting at

Wightwick Manor, which was the home of Charles Mander, whose company

manufactured paints, varnishes and inks. The installation consisted of a

steam driven generator, which supplied 100 volts D.C. for the lamps. A

set of lead-acid batteries was added at a later date.

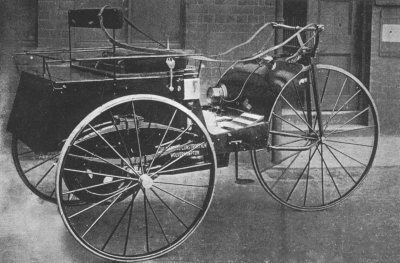

The E.C.C. experimented with motor cars, the most famous of which, the

Electric Dog Cart was built in 1896.

| Reins were used to steer the vehicle because Mr. A.

B. Blackburn who was works manager enjoyed horse riding and so the

vehicle had to be as similar as possible to a horse-drawn one. The

operation of the motor controller was by sliding seat. It was said

by Walter "Wattie" Wall who was an old employee who often drove the

dog-cart, that the arrangement worked quite well when the movement

consisted of sliding the seat backwards, but not so well when it was

necessary to pull it forward. |

Another view of the Electric Dog Cart. |

This difficulty was overcome by screwing a half egg shaped wooden block

to the seat. It rested between the driver's legs and provided the

necessary lock between him and the seat. The vehicle had an interesting

career including a drive through London with the late Duke of Fife as

passenger. In 1896 the car was entered in a race for self-propelled road

vehicles, from the Crystal Palace, London to Birmingham. This was

organised by 'The Engineer' magazine, and there was a 1,000 guinea prize

for the winner. There were 72 entries, but on the day there were only

five runners, and so the race was cancelled. The car however, was highly

commended. The car was eventually broken-up at the works. The motor was

used for many years to drive an ash-hoist in the E.C.C. boiler house.

|

The photograph opposite, shows

an 1897 petrol car, being tested on a 1 in 6 gradient at the

Bushbury works.

Photo courtesy of the late Jim Boulton.

|

An advert from 1896.

|

A visit by

members of the Institution of Mechanical

Engineers in 1897 to the Electric Construction

Company, Bushbury Engineering Works

The present works at

Bushbury stand on a site of about 23 acres. They

were erected in 1889, and the buildings, which

cover an area of upwards of four acres, were

specially designed for turning out heavy

electrical engineering work with facility and

expedition. The whole of the shops and offices

are on the ground level, with the exception of

one first floor for light instruments and arc

lamps. The roofs are of glass and iron,

supported on the cast-iron columns which carry

the traveller gantries, so that there is little

or nothing of a combustible nature. As a further

safeguard, the pattern shop, foundries, and

smiths' shop are detached from the main

buildings, as are also the physical and chemical

laboratories.

The iron foundry is equipped with three

cupolas, capable of turning out 25 tons of

castings per day, air being furnished by a

Root's blower driven direct by an electric

motor. The floor is served by an electric

overhead 10 ton traveller, and by two smaller 5

ton travellers. Recently a ring for a flywheel

magnet, in two pieces, each weighing 11 tons,

has been cast for the Halifax lighting station;

these castings can be seen in the machine shops.

The brass foundry adjoining has eight furnaces,

and turns out a large quantity of plate moulded

work.

The power house contains four water tube

boilers working at 150 lbs. per square inch,

which supply steam to a Robey compound engine of

150 IHP driving by a belt an 80 kilowatt dynamo,

and also to a Willans engine, coupled direct to

an 80 kilowatt dynamo; the two dynamos are run

in parallel to supply the motor and lighting

power. The whole of the shops are driven by

motors, usually belted to short lengths of

shafting, but in several cases driving

individual machines. There are also two other

engines, one of 200 and the other of 100 IHP,

which are used for testing.

The main erecting bay is served by two

electric travellers, having a span of 45 feet

and a travel of nearly 300 feet, which is the

length of each of the bays. It is equipped with

several fine machine tools, notably a planer by

Whitworth, capable of taking work of the largest

size, a faceplate lathe by Muir for work up to

18 feet diameter, and several horizontal boring

machines and other lathes. In this bay and

elsewhere are to be seen parts of several

machines of exceptional size, including 300

kilowatt alternators, 400 and 1,700 kilowatt

continuous current dynamos, and variable ratio

transformers etc.

The press shop, situated to the left of the main

bay, is full of punching and cropping tools of

every description. Here the armature cores are

built up, and the transformer laminations cut.

Overhead is the meter and arc lamp shop. Of the

remaining bays to the right, nos. 2 to 5

inclusive are equipped with high class machine

tools of the usual description, including

lathes, planing, slotting, shaping, drilling,

milling, and profiling machines. Bays 6 and 7

are winding shops. Here a number of girls are

employed in insulating the iron laminations, and

doing light winding work on alternate current

transformers. Instead of the older style of drum

winding, in which each coil crossed over all the

preceding ones, an improvement is here seen in

the Eickemeyer systematic armature winding,

whereby the coil is wound independently of the

armature core, and is readily insulated for any

necessary pressure; and all coils on an armature

are exact counterparts, capable of ready removal

and replacement.

The brass finishing shop contains numerous

turret lathes, universal millers, screwing

machines, and others, driven from two shafts,

each with its own motor. Machinery from these

works is found already in most of the lighting

stations throughout the country; and among the

larger work in hand at the present time are

alternators, dynamos, elevators, lighting plant,

locomotives, tramway motor equipments, rewinding

of dynamos to suit high voltage lamps,

transformers both alternate current and

continuous current rotary. Enclosed factory and

tramway motors, of which examples can be seen in

progress, are meeting with much success. The

number of workpeople employed is at present

about 720; for their use a convenient messroom

is provided on land belonging to the company

outside the works proper. Another portion of

land is divided up into allotments, and let at

low rates to those workpeople who have a taste

for gardening. The engineer and manager is Mr.

A. B. Blackburn. |

|

In 1897 the E.C.C. produced the alternators for the West Brompton

generating Station, and Halifax Generating Station. The company also

completed orders for a variable ratio rotary transformer for Charing

Cross, and another for the Chelsea Supply Company, and tramcars were

built for Hartlepool and Madras.

In 1900 the E.C.C. carried out the re-electrification of the City &

South London Railway.

| There was a recreation ground, which included two

bowling greens, for the bowls club and six tennis courts, four with

grass and two hard courts, for the tennis club. There was a cricket

club, a girl's hockey club, a darts club, a badminton club, an

indoor athletics club, a football team, a table tennis team and a

billiards team. There was an annual sports day and each year a

Christmas party was held for the employees children. Frequent dances

and concerts were also held.

The company also produced a quarterly journal called "Institute

News", which was available for the employees. It contained all

of the latest company news, sports results and a

crossword. There was also an E.C.C. fire brigade, which was

formed in 1903. It was fully equipped and all of the firemen

were trained to deal with any fire that could occur at the

works. |

|

From a 1910 postcard.

|

An advert from 1951. |

|

|

|

|

|

| Return to

the Early Years |

|

Return to

the Beginning |

|

Proceed to

Bushbury Works |

|