The A.J.S. Type 'F'

Receiver - Inside Out

|

Background

The A.J.S. type ‘F’ receiver used the company’s standard T.R.F.

design that was used in most of the A.J.S. non-superhet

receivers. The same components are used in many of the cheaper

two and three valve sloping panel models, the more expensive

table models, the pedestal receivers and the top of the range

Console receiver.

|

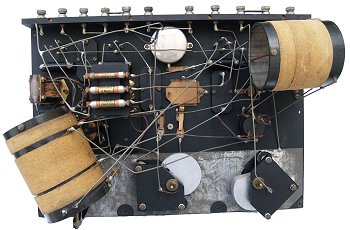

The sloping panel type 'F' receiver with one

of the long wave coils removed. Courtesy of Marco Manfredini. |

Components

Most of the components were made by the company.

Charles Hayward who was in charge of the sidecar section at

Lower Walsall Street works was asked to design a coil-winding

machine so that A.J.S. could produce its own coils. Not only

R.F. coils were produced but also the audio coupling coils that

were a feature of many of the receivers. The company made

everything except for the valves, control knobs and the meter.

It is uncertain as to whether the laminations for the audio

chokes were made in-house.

|

|

The receiver's back panel. Courtesy of Marco

Manfredini. |

|

Part of an advert from 1926

|

The valves used in A.J.S. receivers were initially

made by Mullard and carried the company’s logo. When A.J.S. started

receiver production in 1923, valves used plain tungsten filaments

which had to be heated to around 2,000 degrees centigrade to obtain

adequate emission. These were understandably called ‘Bright

Emitters’ and required high filament currents and had a relatively

short life. They were very expensive and it was common for suppliers

to offer a service to replace a burnt-out filament. Around 1925 this

all changed with the development of ‘Dull Emitters’. These use a

filament that is coated with Barium or Strontium oxide and gives a

much higher electron emission level than plain tungsten. The

filaments now only have to be heated to around 800 degrees and only

emit a dull glow, hence the name. The filament current is greatly

reduced and the valves last a lot longer. Mullard’s dull emitters

are the PM series and these were used in the A.J.S. models for 1925.

From 1926 onwards the company decided to use ‘Six-Sixty’ valves,

which were made by The Electron Company in London. |

Six-Sixty valves were available with different

filament voltages. The types used by A.J.S. with a 2 volt

accumulator were:

|

H.F. amplifier or

detector – S.S.2HF

Detector or L.F.

(non-microphonic) – S.S.2a

Audio output – S.S.10

|

|

| A.J.S. accumulators were made by Joseph Lucas Ltd.,

and the high tension batteries were made by Ever Ready, Columbia and

Siemens. |

|

A receiver front panel showing the

A.J.S. made valve holders. |

| A.J.S. always produced it’s own loudspeakers.

Initially these were horn loudspeakers which used a telephone- type

earpiece with a metal diaphragm. They were available with a wood or

metal horn, but in either case the quality from such a device is

very poor when compared with what we are used to today. Later on

moving iron loudspeakers with paper cones were produced in the

Stewart Street works. Not many of these have survived and it’s hard

to know how they sounded. |

The receiver's front panel. |

The moving iron meter and meter switch.

|

The underside of a type 'F' receiver. |

When A.J.S. radio production ended, Stewart Street

works were purchased by the Symphony Gramophone and Radio Company

and they used moving iron loudspeakers based on the A.J.S. design.

Their loudspeakers were very good indeed and compared favourably

with modern types, so it’s likely that the sound quality from the

later A.J.S. loudspeakers was equally good.

A.J.S. also sold headphones. These were of the standard type of

the day and it is doubtful if they were made in Wolverhampton. |

| The type ‘F’ receiver is a four valve T.R.F. design

consisting of a tuned high frequency amplifier, a detector and two

audio amplifiers. It covers three wavebands; short wave (higher end

of the medium wave band), broadcast (lower end of the medium wave

band) and long wave. A vario-coupled reaction circuit is used which

prevents external radiation on the short wave and broadcast bands

and a metal screen is incorporated to eliminate the possibility of

hand capacitance effects. Provision is made for switching-out the

last two valves, so that the receiver can operate as a two, three or

four valve radio to reduce battery consumption. In the 1920s high

tension batteries were very expensive and the accumulators usually

had to be taken to a local shop for charging, so this kind of

facility would appeal to purchasers. Each valve is fitted with a

plug-in resistor in series with the filament so that a wide range of

valves with different filament voltages could be used. A range of

suitable plug-in resistors was available from A.J.S. dealers. |

| The high frequency amplifier has separate aerial and

output tuned circuits and is neutralised. The coils are wound on

large diameter formers using heavy gauge copper wire. In the mid

1920s this was considered to be good practice because it offered

excellent mechanical stability and a low internal capacitance and

resistance. |

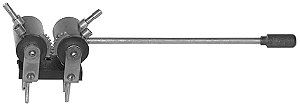

The plug-in long wave coil holder and coil

arm. Courtesy of Marco Manfredini. |

|

The basket wound reaction coil. |

|

An A.J.S. patent audio coupling choke.

The leaky grid detector also provides feedback for reaction and

the audio stages are choke coupled. A.J.S. always favoured choke

coupling and claimed that it produced a higher quality sound than

conventional transformer coupling. Choke coupling was never popular

and was developed because a choke was cheaper to produce than a

transformer and the low dc resistance of the coil meant that the

valve anode was at a higher voltage than when used with an anode

load resistor so that a larger audio signal could be produced. This

was felt to be important because at the time most receivers were

battery powered and so the HT voltage was not that high. In practice

any improvement would only have been marginal.

Circuit Description

High Frequency Amplifier |

A simplified version of the high frequency

amplifier showing just the short wave and broadcast band components. |

Broadcast and Short wave bands

The aerial tuned circuit consists of L1 and C1, L1 being tapped

for short wave. La is the aerial coupling coil which acts as a

coupling capacitor (one end is not connected).

The output of the

amplifier is tuned by L4 and C2. L4 is tapped for short wave and is

mounted at right angles to L1 to prevent feedback.

The internal

capacitance of the valve could produce instability and this is

eliminated by neutralising circuit L5 and C3.

The negative feedback

from L5 is adjusted by C3 to counteract any positive feedback

resulting from the valve’s internal capacitance.

|

| Two terminals on the front panel, normally linked,

allow for the connection of an external tuning coil and two

terminals on the back panel (labelled R and R and normally linked)

in series with V1 grid, allow an A.J.S. Patent Rejector Circuit to

be used with the receiver. |

Long

wave band

External plug-in aerial and anode tuned circuits are used on

long wave. Aerial coil L2 and output coil L3 plug into a switched

socket on the front panel. When the coils are removed their

connections on the socket are automatically short-circuited.

In use

long wave is selected on the rotary wavelength switch and the coil

arm is raised. If the arm is fully lowered the coils are

switched-out. The arm controls the coupling between the coils.

They

are connected so that positive feedback will result if the coils are

closely coupled and so the arm acts as the long wave reaction

control. L4, L5 and C3 remain in circuit on long wave to provide

neutralisation and the aerial is directly connected to the aerial

tuned circuit.

|

A simplified version of the high frequency

amplifier showing just the long wave components. |

| A range of plug-in coils was available allowing

the receiver to operate down to 55KHz. |

|

The detector.

|

Detector

The detector is a conventional leaky grid

detector, directly RC coupled from V1 anode. L6 is mounted

inside L4 and is rotated by the reaction control knob to alter

the amount of coupling between the two coils.

This provides

positive feedback for reaction. L6 is a very thin coil so that

the coupling between the coils at zero reaction can be reduced

to an extremely low value. It also provides an extremely fine

and precise reaction adjustment.

This type of coil used to be

described as ‘basket wound’ and sometimes called a basket coil.

On the short wave and broadcast bands this is the only reaction

control, but on long wave the main reaction is adjusted by the

coil arm and the reaction knob becomes a fine reaction control.

C4 filters out any remaining carrier wave and the audio signal

is developed across audio coupling choke L7.

|

|

Audio Amplifier

The first audio amplifier is RC coupled from the detector

by C6 and R1, the audio output being developed across coupling

choke L8.

The two coupling chokes L7 and L8 are mounted at right

angles to one another to minimise feedback in the audio

amplifier. The output valve is RC coupled to V3 anode by C7 and

R2 and provides a direct output for a horn loudspeaker, moving

iron loudspeaker or headphones.

The loudspeaker positive

terminal is directly connected to the HT(3) + terminal on the

back panel so that the audio output can be supplied from a

separate, or higher voltage supply.

|

The two-stage audio amplifier.

|

The receiver front panel.

|

We would like to thank Marco Manfredini for

providing some excellent photographs.

We would also like to add technical details of other A.J.S.

receivers and if anyone has any information please email the

webmaster.

|

|

Return to the

A.J.S. section |

Return to the

Technical Menu |

|

|