| The Star Aluminium Company Limited was founded in

1933, and quickly acquired half of the vacant A.J.S.

site at Graiseley Hill.

The business was a wholly owned subsidiary of the

Swiss Aluminium Group, Alusuisse. The factory, which in

the early days fronted onto Marston Road, was called

Alustar Works.

The firm’s main product, aluminium foil, was produced

from aluminium ingots, which after casting into slabs

were rolled in a rolling mill to produce a range of foil

thicknesses, down to less than one-tenth the thickness

of a human hair. |

|

|

An advert from the late

1930s. |

|

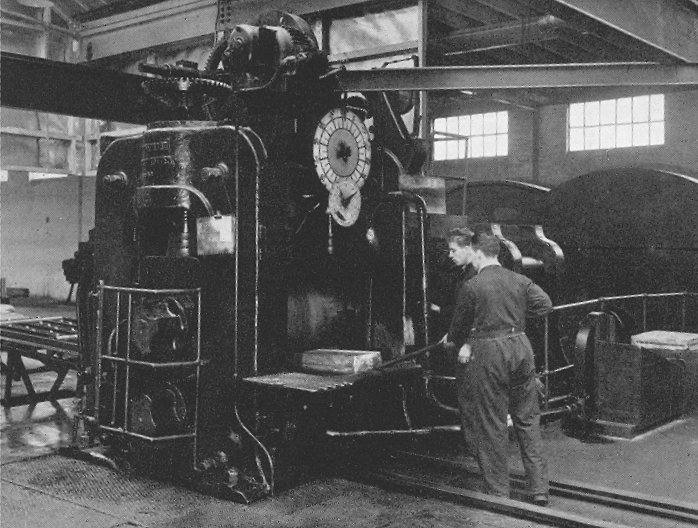

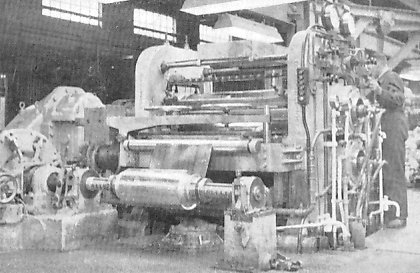

A hot rolling mill for

aluminium billets in the late 1930s. |

|

An advert from 1948. |

|

|

|

|

An advert from 1953. |

|

An advert from 1956. |

|

|

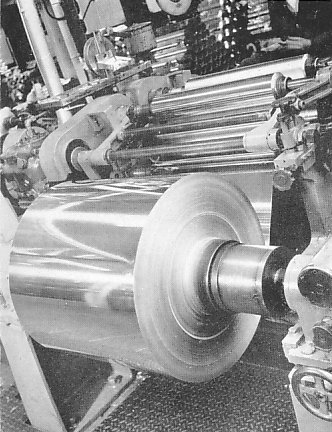

One of the rolling mills on the

Graiseley Hill site. |

The foil’s primary use was for packaging such items

as cigarettes, confectionary, foodstuffs,

pharmaceuticals, and also for cooking and storing food.

It became a familiar sight as a cap for milk bottles,

and a popular packaging for dairy products, baked

foodstuffs, and frozen food.

Star House-Foil and Star Garden Foil were marketed

for the housewife and the gardener. |

|

Because the foil could be produced

in a range of thicknesses to suit the customer, it found applications in many industries, including shipbuilding,

aircraft manufacture, electronics, and engineering

construction.

Its many applications in

electronics included foil for capacitors, cable

screening and transformer windings.

Star foil was supplied in reels of

up to 56 inches wide, the widest foil made in the UK. It

could be laminated to paper, film, or board, and readily

accepted colouring, or printing.

Other applications included rigid

foil containers (‘Sealway’ containers) for the bakery

trade to house cakes or meat pies, and for convenience

food.

It also found a use in the

decorating trade as ‘Star Wall Foil’, an effective

protection against damp. |

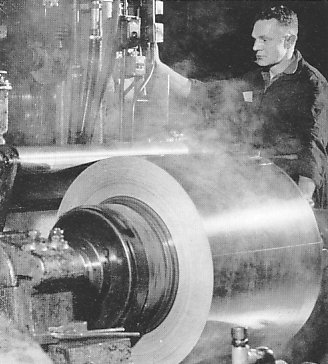

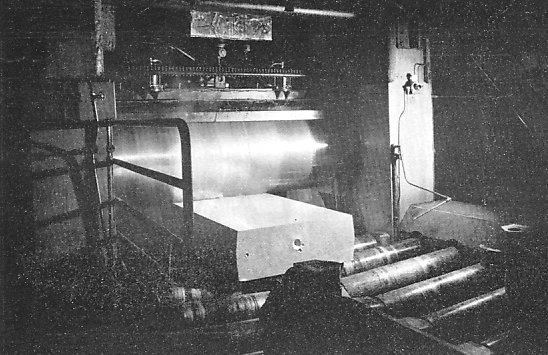

Reducing foil thickness in the

rolling mill. |

|

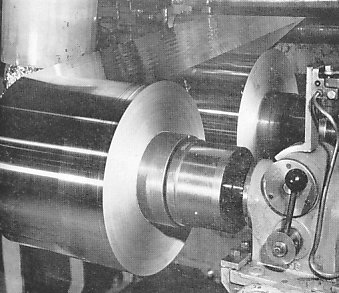

Double foil rolling. |

The foil sold extremely well, and

by 1946, 50 tonnes were produced each week.

In the mid 1960s further extensions

were made to the Marston Road site, extending it the

Penn Road, with a new entrance at number 97 Penn Road.

Additional premises were acquired

in Sedgley Street, Wolverhampton, Primrose Avenue,

Fordhouses, and in 1956 at Bridgnorth, making the firm

the largest manufacturer of aluminium foil in Britain.

By 1961 the company had over 1,000

employees.

|

| Star foil became a household name, and sales greatly

increased. From the two rolling mills at Wolverhampton

and Bridgnorth, the company's fleet of lorries delivered

foil to all parts of the country, and directly to Europe

via the cross-channel ferries. |

The new factory extension on the

Penn Road. |

|

Penn Road entrance in 1970. |

|

The finished product coming off

the rolling mill. |

The company ran a successful sports

and social club at 72 Temple Street, Wolverhampton. It

was above the Palais de Dance.

The works at Wolverhampton

continued to operate in parallel with Bridgnorth until

1981 when the decision was taken to concentrate

production at Bridgnorth. This resulted in the closure

of the Wolverhampton factory.

In 1996 production at Bridgnorth

exceeded 1,000 tonnes per week. A lot of investment has

been made at the site, including a new hot mill,

slitting line, and annealing furnace.

In 2000 the

business merged with the Canadian company Alcan, and in

2001 the Bridgnorth factory, now called

Bridgnorth Aluminium, was acquired by Elval S.A., the

sole Greek producer of flat rolled aluminium products. |

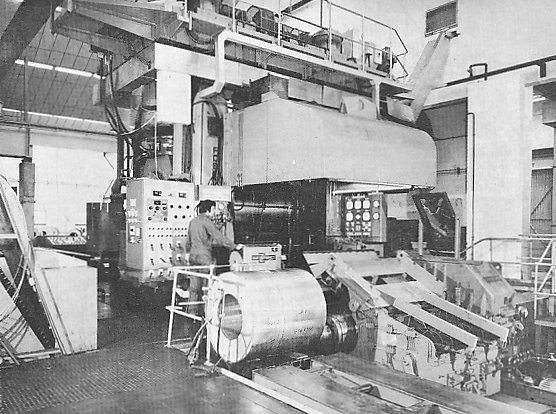

A slab of aluminium enters the hot mill at the

start of the rolling process.

A final view of a rolling mill.

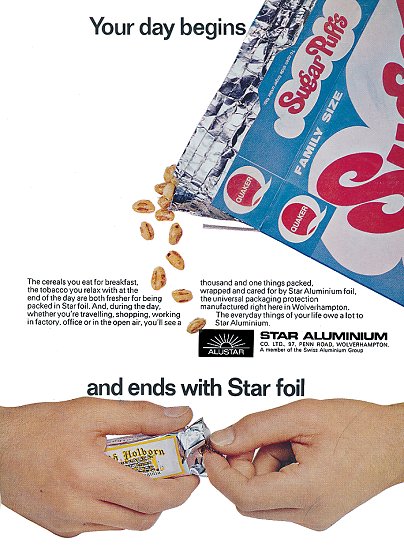

An advert from 1959.

An advert from 1972.

|

Return to

the

engineering hall |

|