The Villiers Engineering Co. Ltd.

Some Technical Details

|

This section includes a few notes and details of the

mechanical and electrical systems that were used in Villiers engines.

One of Villiers famous motorbike engines of the late 1920s

was the 'Standard Sports'. It was a 172c.c. engine with cast iron piston,

fixed cylinder head, twin exhaust pipes and variable ignition, which was

fitted to all Villiers engines at that time. The 'Standard Sports' also

included a large silencer that had 16 times the volume of the swept volume

of the engine. It also had a drip feed lubricator. A higher performance

engine was the 172c.c. 'Super Sports T.T.' which had an aluminium die-cast

detachable head and flywheel magneto. It was also fitted with the Villiers

patent lubrication system which had no moving parts. The quantity of oil

supplied depended upon the engine load instead of engine speed. The

crankshaft journals were drilled with four lateral ports, the outer pair of

which, were placed to permit a small amount of the compressed gases in the

crank chamber, to be forced out through grooves in the main bearing bushes,

to a union on the front of the crank case and up into the oil tank of the

engine. In this way pressure was built up in the space above the oil in the

tank and the lubricant was forced up a vertical pipe into a flush-fitting

drip feed. From there it flowed through a pipe and into the cylinder. In a

similar way oil was also fed to the crankshaft bearings through separate

passages and through the drilled crankshaft to the roller bearing.

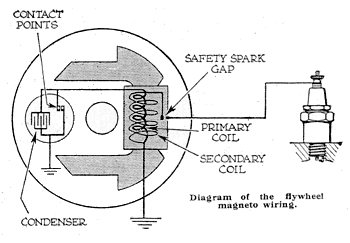

Villiers produced simple and reliable engines, with few moving

parts. One of the company's successful innovations was the

flywheel magneto, in which the high tension voltage was

generated within the flywheel casing, the only moving part being

the flywheel itself. Magnets and pole pieces were attached to

the inside of the flywheel and a voltage was induced in a

stationary coil in the centre. This technique was extended to

provide the low tension voltage for electric lighting and

battery charging. |

The flywheel magneto.

|

The whole arrangement was extremely reliable. Apart from

the spark plug, the only item that needed occasional attention was the

contact points in the contact breaker.

The points needed to be kept

clean and the gap correctly set. Failure to maintain a sufficient gap

led to overheating and considerable difficulty in starting. |

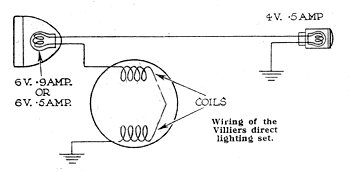

| The wiring diagram of the simple lighting set which did

not include a battery. It produced an A.C. voltage to light the head

lamp and tail lamp.

Due to the special winding of the coils, a rapid

rise of voltage was obtained. This was almost constant over 25m.p.h. |

|

|

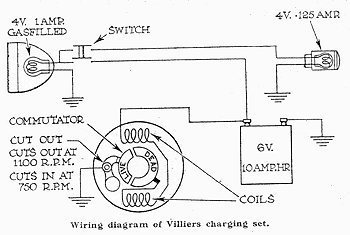

The charging set rectified the A.C. voltage induced in

the lighting coils by a commutator, which was carried on the flywheel.

A

centrifugal cut-out was mounted on the flywheel to prevent the battery

discharging through the lighting coils, when the flywheel was

stationary. A Nife accumulator was used which needed to be topped up

with distilled water instead of acid. |

| Care was required when doing this, as the liquid

electrolyte contained caustic potash which would attack the hands or

clothes. |

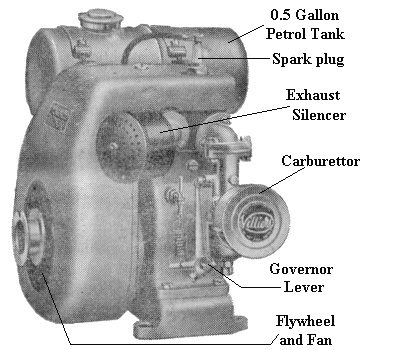

The Villiers Mk.10 stationary engine. |

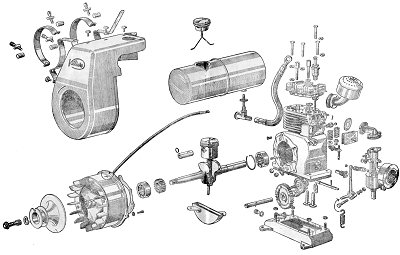

The Mk. 10 Villiers stationary engine was a typical

Villiers product. It was simple, neat and compact, with few moving

parts. Because of this simplicity, Villiers engines were reliable and

easy to maintain. The engine included the Villiers flywheel magneto,

with the engine cooling fan mounted on the outside of the flywheel.

Most

of the parts were made in-house and additional parts were available for

petrol-paraffin running. |

| The engine had a 50mm bore and a 50mm stroke. The total

swept volume was 98c.c. and the engine could deliver 1h.p. at

2,000r.p.m., and 1.3h.p. at 3,000r.p.m. It was air-cooled and used an

oil-wetted type of air filter.

The capacity of the fuel tank was 0.5

gallons and the lubricating oil sump held one pint. It was fitted with a

Lodge spark plug and Villiers carburettor. |

A drawing showing the parts that make up the

Mk.10. |

The Villiers Mark 3 engine. |

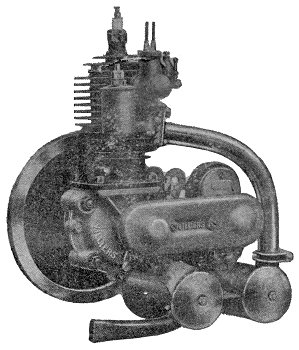

The Villiers Mark 3 engine was introduced in 1920 and

was one of the last engines made by the company before the introduction

of the flywheel magneto. It used the conventional type of chain-driven

magneto with horse-shoe magnets and a conventional flywheel.

The engine

was designed to allow easy access to the various parts for servicing.

The carburettor was attached almost at the top of the cylinder wall to

allow access to the jet. The spark plug was moved to the top of the

cylinder, to isolate it from the top cooling flange and it kept

remarkably cool.

The inlet gas was led through an induction passage,

cast into the cylinder assembly. This arrangement avoided condensation

and gave greater efficiency because the gas was warmed on its way to the

crank case. Like many Villiers engines, it included double silencers and

was very quiet in operation. |

Another view of

the Mark 3. |

|

|

|

|

|

|

| Return

to Other Products |

|

Return

to the beginning |

|

Proceed

to Villiers adverts |

|