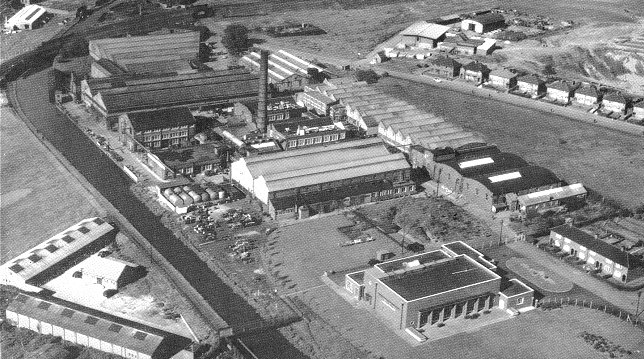

| Mander-Kidd Limited was one of the country’s largest

manufacturers of printing ink. The Heath Town factory had the

most up-to-date equipment of its kind, and produced all kinds of

printing ink for most of the printing processes that were in use

at the time. Inks were produced that were suitable for use with

all kinds of paper and boards, metal foils, and plastic films.

Ink is a complex medium, with exacting requirements. Colour

consistency is essential, across a whole range of colours, and

uniformity, so that the same result is achieved each time. Ink

must not dry in the printing machine if left overnight, but has

to dry in a split second on paper. Some inks are as thick as

putty and others have to flow like milk. |

|

The Heath Town factory. |

|

Ink also had to keep-up with advances in

technology. New machines, materials and processes were

constantly introduced, so a large amount of investment had to be

put into research and development. Well-equipped and

sophisticated laboratories were essential, along with qualified

and experienced laboratory staff.

Raw materials were imported from many

countries including Africa, Brazil, Canada, Central America,

India, Korea, the Middle East, the Philippines, Scandinavia,

Spain, and the United States. The all important colour pigments

came from Britain’s coal mines. They were derived from the

distillation of coal tar, with the careful addition of

controlled quantities of rare metals such as tungsten and

molybdenum. Other important raw materials were carbon black, a

product of petroleum, and titanium, zinc and lead which were

used to produce white ink. |

|

One of the raw material stores. |

| Samples of all of the materials were taken on arrival, and

thoroughly examined and tested in the laboratory before being

released to the factory. This was essential to ensure that high

standards of quality and consistency could be maintained.

Careful stock control was also important to make sure that

adequate stocks were available when supplies were interrupted

due to unforeseen circumstances. |

|

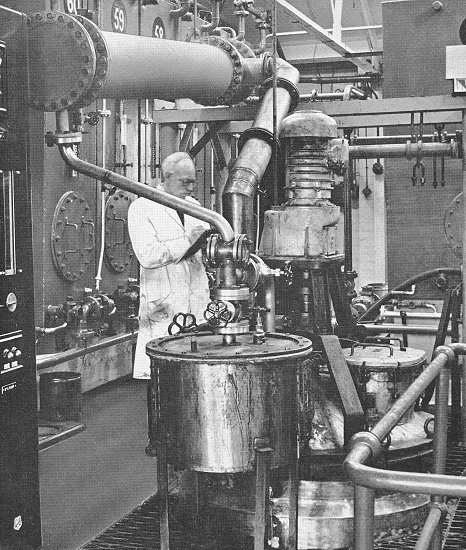

Inspecting one of the varnish pots. |

One of the most important ingredients is varnish, which is

the basis of the ink. It carries the colour, determines the

ink's behaviour in the printing machine, and the quality of the

ink film on the printing surface. It was made in the varnish

plant using the most up-to-date techniques. Manders produced

varnish for over two hundred years, during which time the

process considerably changed.

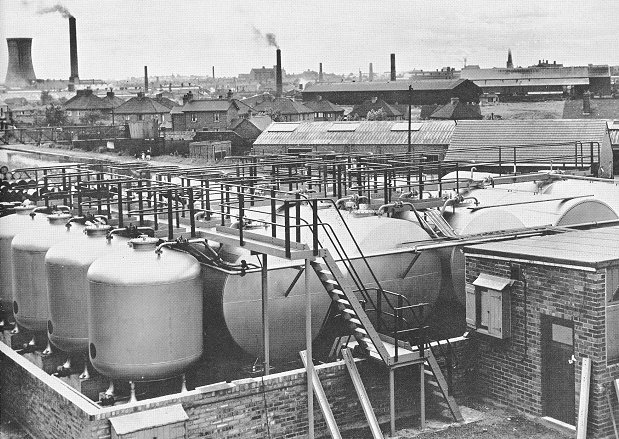

Originally heated linseed oil or semi-drying vegetable oil

was used with a natural gum such as Congo Copal, which had been

previously treated to render it soluble in the oil. This was

replaced with a range of vegetable and other oils that were

stored in a large 'tank farm'. Quantities of chemically pure

compounds were added to the oil, and the mixture was heated in a

closed vessel, which could hold about two tons of raw

ingredients. A batch would usually be finished in less than 24

hours, during which time the temperature was accurately

monitored. |

|

The tank farm where 50,000 gallons of

oil was stored. |

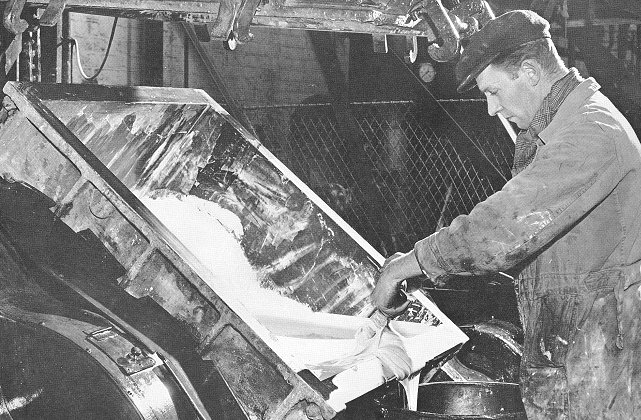

| Throughout the process, by-products such as water were

continuously removed, to leave a synthetic varnish with the

precise qualities that were required for the ink. Periodically

samples were taken, and the viscosity measured. When it was

exactly right, the varnish was piped to a set of coolers, and

through a large filter press to the storage tanks. To produce

the ink, pigments were thoroughly blended with the varnish, to

which driers and reducing mediums were added in correct

proportions. The ingredients were then thoroughly mixed in

powerful mixing machines that could each handle half a ton at a

time. The machines occupied a large part of the floor space at

the factory. |

|

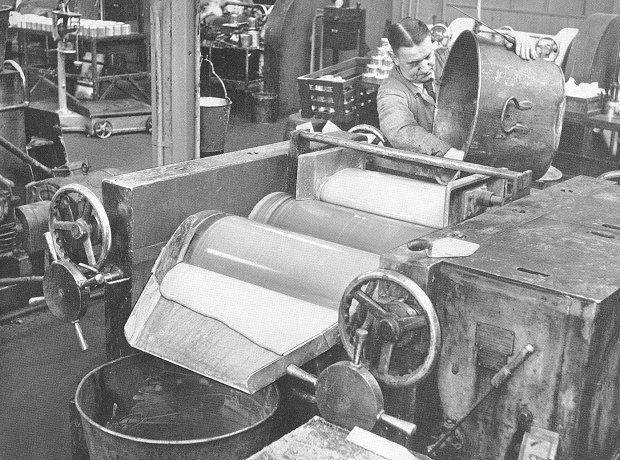

Emptying one of the mixing machines. |

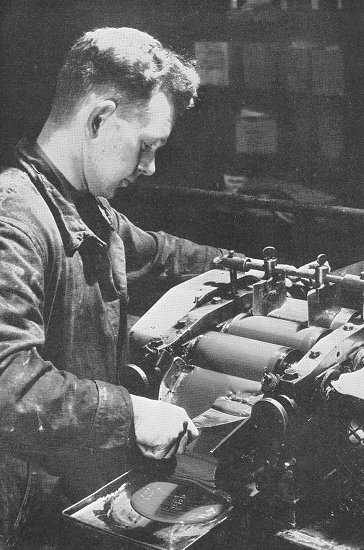

| When mixed, the ingredients were taken to the grinding mills

which dispersed the minute pigment particles evenly throughout

the varnish medium. The mills had three water-cooled,

electrically driven, polished steel cylinders that were geared,

so that the second cylinder rotated slightly faster than the

first, and the third cylinder rotated faster again. The degree

of 'nip' between the cylinders was carefully adjusted according

to the kind of ink being made. |

|

Part of the main mill room showing

some of the three roll mills. |

| The operators would pass the ink through the mill for

anything up to eight times depending on the type of pigment, and

the requirements of the formula. A sample would then be taken to

the testing room to be compared with a standard sample. The

properties, including colour and consistency, tackiness and

drying speed were examined by an expert, and when correct, the

batch would be measured into cans, which were sealed and

labelled for despatch. Every can was stamped with a code number

so that the whole history of its manufacture could be traced. |

|

A batch of ink nearing completion on a

Torrance three roll mill. |

| The company also produced batches of special

inks that were different in some way to normal inks, and catered

for customer’s unusual requirements. They were often produced

in small quantities from a mixture of standard products,

sometimes with additions, and were ground by hand on mixing

slabs or benches.

Hand mixing a special colour on a slab. |

|

|

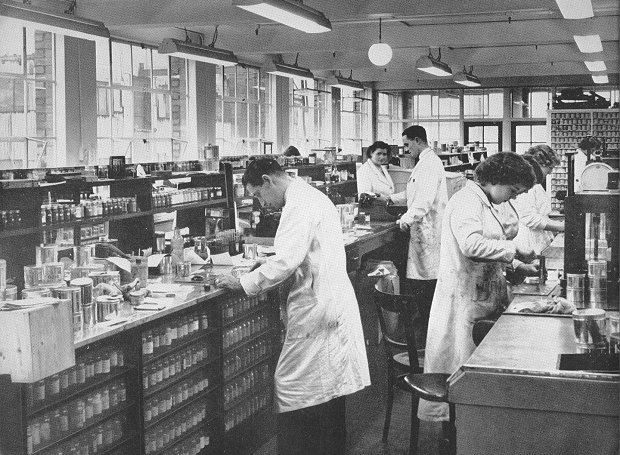

One of the laboratories with some of

the large collection of pigment standards in the foreground. |

| The firm’s laboratories were an essential part of ink

manufacture. Every stage of production was carefully monitored

and subjected to stringent physical and chemical tests.

Laboratory staff also prepared formulae for new inks, and looked

after special matchings to customers' orders, and matchings to

paper. The best equipment was used, including extremely accurate

electrically controlled balances, devices for measuring colour

by spectrum analysis, viscometers, miniature grinding mills, and

a great variety of chemical apparatus. |

|

There was also a light fastness testing machine (seen on the

left) which could subject sample panels to the equivalent of

several months' exposure to sun and rain in a few hours, and an

automatic machine for determining the printed film's resistance

to abrasion. There were also machines to test every physical

and chemical property of ink so that the result could be

recorded in mathematical terms. |

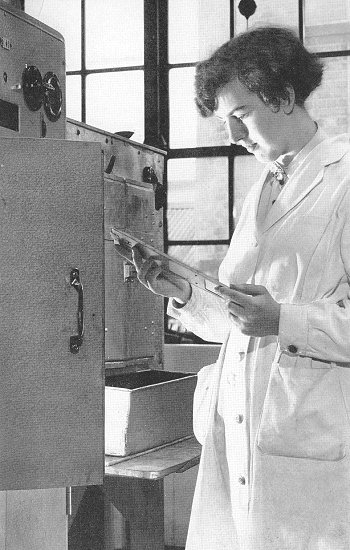

| Testing the viscosity of a new batch

of varnish in a thermostatically controlled bath. |

|

|

A carton ink being tested for abrasion

resistance with a Sutherland rub tester. |

| Producing a trial quantity of ink

on a miniature three roll mill. |

|

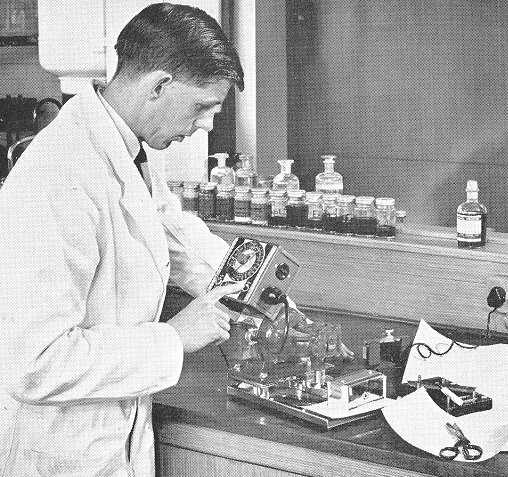

| A continuous programme of research into possible new

materials and processes was undertaken. New papers and other

printing surfaces were minutely examined, and a close eye was

kept on developments in the printing trade so as to find a way

of meeting future requirements in advance. |

|

One of the research laboratories. |

|

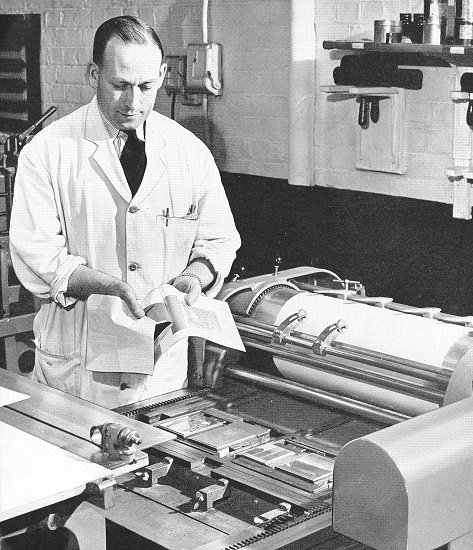

The factory also had a printing department,

equipped with a full range of printing machines. The

letterpress section had a flatbed Miehle, Heidelberg and Arab

platens, and a Soldan.

The offset section had an A.T.F. Chief and a Rotaprint, and

the gravure and aniline section had a Chambon.

The machines allowed the operators to test the performance of

inks under normal workshop conditions.

A proofing press in the machine room. |

|

The letterpress section in the

printing department. |

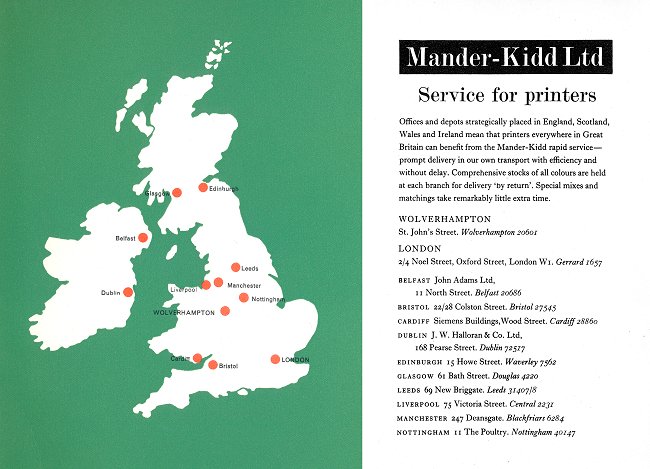

| After manufacture, the ink was quickly and safely

distributed to printers. Mander-Kidd was ideally situated in the

centre of the country, and able to service all areas through the

London factory or one of nine branches. All of them carried

large stocks of inks and had their own delivery service. Some of

them were also able to mix special matchings on the spot, and

the London factory had manufacturing and laboratory facilities

to cope with urgent orders. |

|

UK factories and branches. |

|

There were also three factories in South

Africa, one in Rhodesia, another in Australia, and over sixty

agents throughout the world. Mander-Kidd offered a service that

was second to none. It was greatly appreciated by the vast

number of customers who regularly used the products. |

�

|

|

|

|

|

Return to

Heath Town |

|

Return to

the contents |

|

Proceed to

George

Cox's Memories |

|