|

At the works one gathers the impression

that success on a very large scale indeed has come somewhat unexpectedly,

for they are hard put to keep pace with the demand. There is not a square

foot of floor space to spare, not a single machine that is

not hard at work day and night, and not a man who is not

pulling his weight. There is no room for duds-mechanical or

human. Of course, with the cars being built on

such a very large scale a “flow" system of production is essential, and the

Clyno is singularly well adapted to the conditions of its

manufacture, for the design is ideal for rapid assembly.

This is apparent so soon as one enters

the works, for one can literally see the cars taking shape before one's eyes.

Almost the whole of the car is manufactured in the works at

Wolverhampton with the exception of the engine, which is made by a well-known firm of

specialists in the Midlands, and the bodies. Unlike most of the works engaged on

producing cars in very large numbers, no moving assembly

tracks or other “American" methods are adopted, although of

course a “flow" system is in force.

One is greeted at the entrance of the

works with a giant stack of chassis frames: these are taken

from the stack and first the springs, front axle and front

wheels are secured. The car is then pushed stage by stage

along the floor of the big assembly shop. The rear axle

unit, with the gearbox which has been previously assembled

in a different shop, is then run into place (with the road

wheels fixed), the engine with the clutch shaft in place

lowered on to the frame from above, the steering gear column

and connections assembled; the fitting of the radiator,

brake rods and so forth completes the assembling.

An engine being lowered onto the chassis frame

in the assembly shop.

All this happens in a remarkably short

space of time, the car finishing this first stage in its

career at the opposite end of the shop to the stack of

frames where it started. It is then turned round and the

body is dropped into place so that the car can be pushed

stage by stage to the original end of the big assembly shop

whilst the wiring up, trimming and fixing of hood and side

curtains and so forth are carried out.

The car is then turned round again and

progresses back down the shop to be elevated near the centre

on to a platform which allows mechanics to make sure that

everything is in order beneath it and that all parts needing

oil or grease are well supplied before it emerges from the

far end of the shop for a road test.

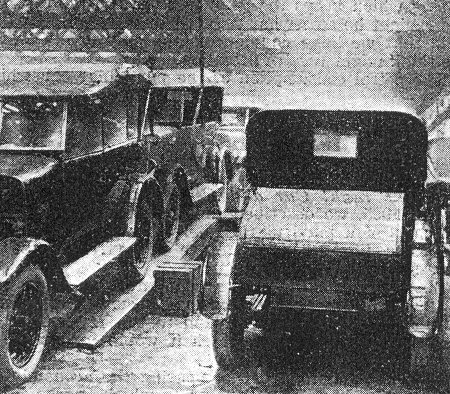

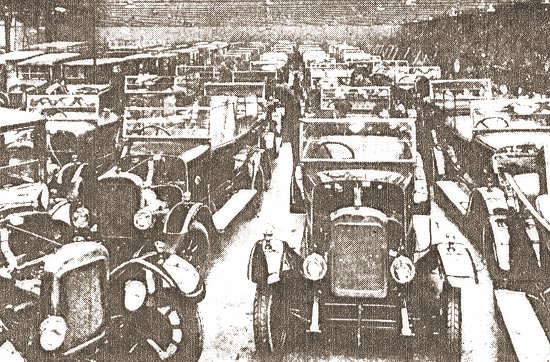

Final assembly.

The thing which impresses one

principally in the large assembly shop is the extraordinary

amount of space which so many manufacturers waste; for in

this single shop the whole of the actual building of the

cars is carried out in greater numbers and with less delay

than in many giant works equipped in a lavish manner and

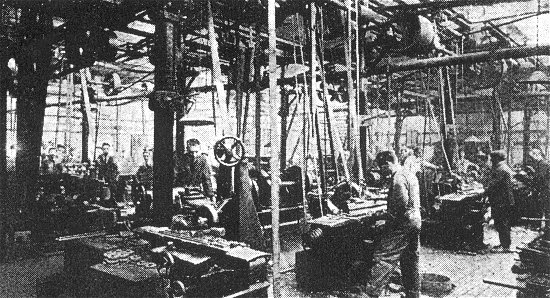

planned on the most up-to-date lines. In the machine shops at the Clyno works

one observes the same unobtrusive efficiency that is

noticeable in the assembly shop, the work being carried out

very rapidly indeed and with no waste of time or material.

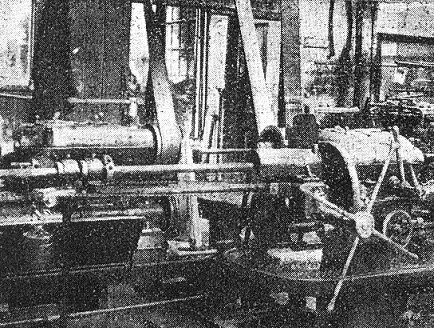

The machine shop.

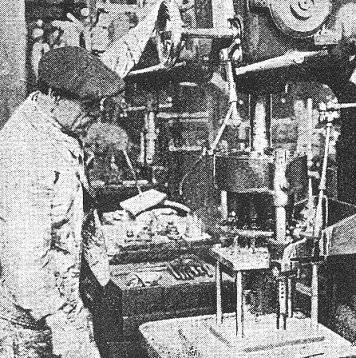

A multi-drilling machine, drilling 8 holes in one end of the axle.

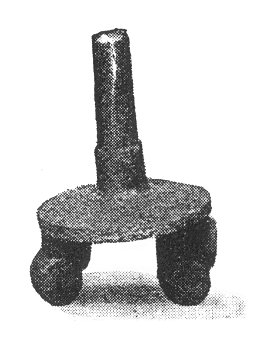

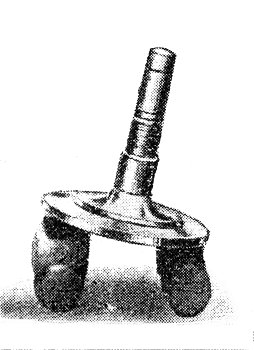

A case in point is illustrated by the

accompanying photographs, which show a stub axle in the

rough and partly machined. For turning the two faces,

machining the spindle to two different diameters

and cutting the thread upon it six minutes are allowed;

actually this time allowance is on the generous side.

Another operation which typifies the efficiency of the

machine shop is the production of gearbox layshafts machined

complete from 1¾inch steel bar at the rate of four minutes

per shaft-a somewhat remarkable achievement.

|

On the left is a

forged stub axle blank. It is shown on the right

after machining. An operation that took just 6

minutes to complete. |

|

Machining a gearbox layshaft. It took

just 4 minutes.

With regard to the equipment, the Clyno

works are very well provided, the machines which are

installed being of the best, and in many cases designed

specifically for the work which they produce.

So far as the assembly of axles and

gearboxes is concerned, the gearbox of the Clyno is on the

front end of the torque tube. Little need be said except

that precision methods in the manufacture of the parts

ensure no delay in putting them together, whilst so

straightforward is the design that comparatively unskilled

labour can be employed.

The chassis erection shop.

We understand that at the present time

there are something like a thousand men on the pay-roll at

the Clyno works, whilst, of course, many hundreds more are

busy in the production of the engines and the coachwork. The

company is a firm believer in the fact that a car to be

described as a British car must be British throughout,

therefore every detail of the Clyno is of British

manufacture.

From the Light Car and Cyclecar magazine, 12th March, 1926.

11hp. Clynos in the assembly shop. |