| Decline and Fall

Around 1926 things started to get a little

shakier, as if reflecting the problems which Nobel Industries were

having. In 1927 they amalgamated with Brunner Mond Limited to form ICI,

a vast conglomerate of which John Marston Limited was but a small part.

Initially this had little impact at the works, Sunbeamland remained

under the control of Sidney Bowers, and Works Manager, F. T. Jones. |

|

The company did not do badly under ICI, but

motorcycles were not their chief interest, and this was certainly

felt at Marstons, where 1927 became a year of uncertainty for the

workforce.

Of course the general depression did not help.

Motorcycle sales slumped and the company contracted. The machines

were still good ones, but they had undergone a great change, no

longer being the Rolls Royce of motorcycles, but a considerably less

highbrow machine.

Luckily John Marston had decided to begin producing radiators in

1906 for the growing car industry, initially in Temple Street, then

at Sunbeamland.

The radiators were a very popular product, and sold well,

eventually becoming the company's most important asset.

Radiators were not only made for road vehicles, versions were

available for aircraft, and industrial applications. |

An advert from 1907. |

|

An advert from 1919. |

| An extension to the works |

|

The Elms, Penn Road. |

On the opposite side of Penn Road to Sunbeamland stood an old

square red brick house called the Elms. It was built in the late

18th century, and was the family home of John Mander and his first

wife Esther. John was the founder of Mander Weaver and Company,

manufacturing chemists in Cock Street, Wolverhampton.

Because of John's profession, the house became known as "Gallipot

Hall" after the glazed earthen pots that were used for storing

medicines. |

|

The house had extensive grounds, and during the last years of

its life was known by many people as the doctor's surgery because it

was occupied by general practitioner, Dr. Brookes.

Around 1926 the

house and grounds were purchased by John Marston Limited to make way

for a new factory building.

The house was demolished in September, 1926.

|

The Elms Works in the mid 1950s. |

|

A plan of Elms Works. |

The new building, known as Elms works,

or Clock Works because of the clock on the roof, opened in 1928. It contained the Service and Spares Department run

by Joe Dudley, the stores run by Freddie Simpson, the Competition

Department, the canteen and Social Club, and offices. At

the time, the staff were actively encouraged to participate in

social and sporting activities outside working hours. As a result

the Sports and Social Club upstairs acquired snooker tables, and

became the meeting place of many sports teams, and even the

'Beamers' dance orchestra. Sporting activities included bowling,

cricket, fishing, football, and tennis.

The canteen was also the site of the official celebrations when

Charlie Dodson won the Isle of Man Senior T.T. in 1928. This was the

company's third T.T. win. |

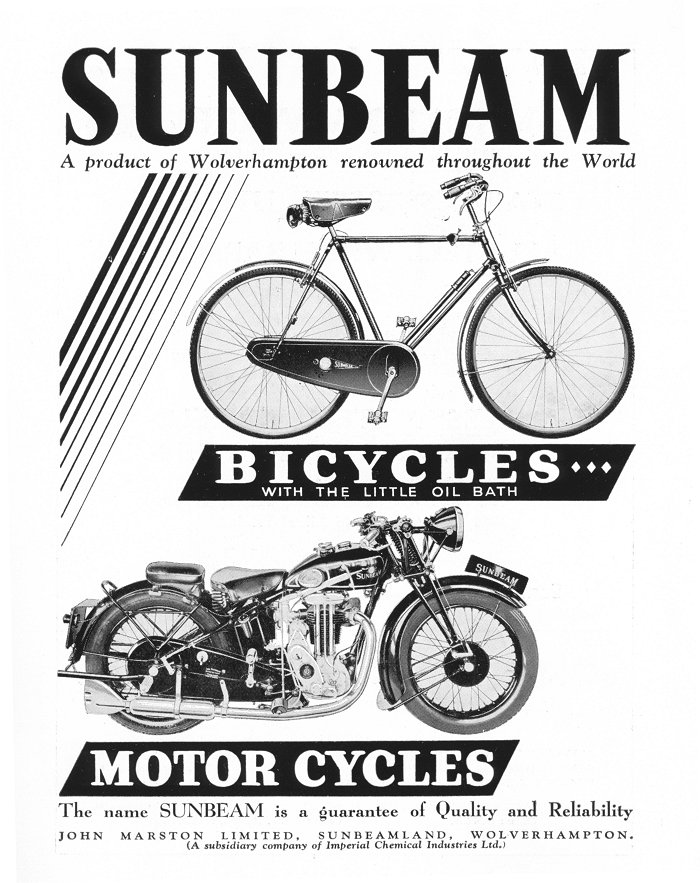

An advert from 1928.

| In November 1929 production of the Deloford portable boat

began in an empty workshop on the top floor. The boat, made of

plywood and rubberised sheet, could be packed flat for easy

transportation. A lot of orders were received, the venture

appears to have been a great success. |

|

|

|

|

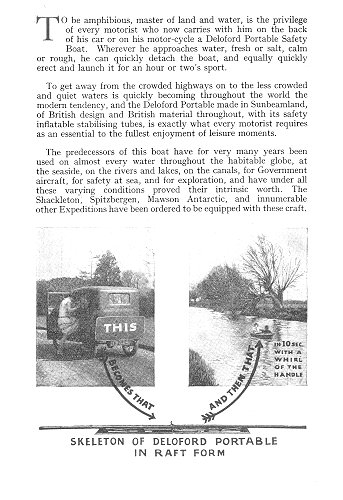

The first

and second pages of a Deloford leaflet. |

|

|

|

|

|

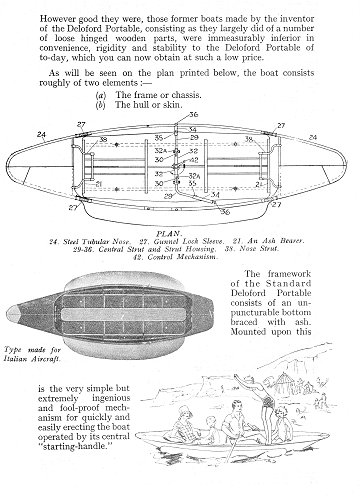

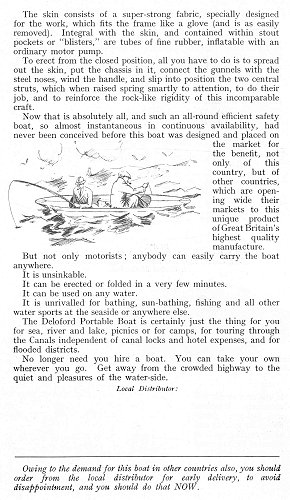

The third

and fourth pages from the Deloford leaflet. |

|

|

In 1929 Sunbeam finally adopted

the saddle tank, which had been invented by Howard Davies in 1924. It

was a significant year because

Charlie Dodson won the Senior T.T. for the second year running, at an

average speed of

72.05 m.p.h. He also made the fastest lap in

30 min.47 seconds at a record speed of 73.55 m.p.h.

Team mate Alec Bennett came

second and Arthur Simcock finished in seventh place. To cap it all

Sunbeam also won the team prize for the third year in succession. Sadly

this was the company's last successful Isle of Man T.T.

1930 started badly. Sidney

Bowers was taken seriously ill, and on January 26th, replaced by

accountant Graham Bellingham. Sales were falling because of the

depression, and a new range of models was announced in readiness for the

Motorcycle Show. Sidney Bowers' departure

heralded the start of many changes that would take place at the works

during the next few years, beginning with a costing exercise in the form

of a time and motion study. |

John Greenwood (standing) and Charlie Dodson,

after his T.T. win in 1928. |

| The inspection was carried out by experienced employees who

timed and checked all operations and procedures. This must have

worried many of the 600 staff. The

study led to a rationalisation process which ended many of the

old-fashioned, uneconomical processes, such as the large amount of

hand soldering of components. For the first time many components

were purchased from other manufacturers rather then made in-house.

One of the conclusions of the study was that many of the machines

were worn out, but as investment was not a priority at the time,

nothing was done about it. |

|

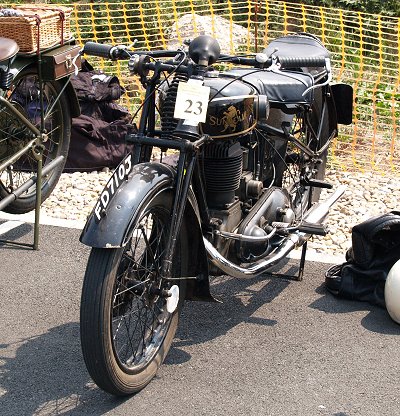

Mark Homer's Sunbeam Lion. |

A number of changes to the

range of models took in 1930. The Model 6 'Longstroke' was

restyled and called 'The Lion', which was named after one of the ICI

trademarks. The design of the fuel tank was a departure from usual

Sunbeam practice. The soldered petrol tank was replaced by a

bought-in welded and chrome plated tank.

There was also the new

344 c.c. Model 10, which had an overhead valve engine, and

was designed by Stephenson and Greenwood. It had a three speed

gearbox, was lightweight and economic on fuel. Fuel consumptions of

over 100 m.p.g. were not uncommon.

In the new range, the

Druid-type forks were replaced by Webb-type centre spring forks, and

soldered petrol tanks were discontinued (except on the Model 90)

in favour of the welded, chrome plated bought-in type that was

fitted to the 'Lion'. |

|

In 1931 prices were reduced due to the

continuing depression, and the company adopted more internal

economies in an attempt

to reduce manufacturing costs.

Sunbeam machines continued to take

part in trials events, but racing was discontinued. George Dance left

the company and moved to Diamond Motors, and then went into market

gardening.

August 1931 saw the introduction of

a 2-stroke outboard motor for boats. There were

three versions, a 340 c.c. twin, a 102 c.c. single, and a 78 c.c. single.

It was produced

at Wolverhampton for several years, and distributed by Merlyn

Motors, Whiteladies Road, Bristol. It became known as the 'Seagull'

outboard motor. |

John Grew's Model 6 from 1930. |

|

The 78 c.c. and 102 c.c. versions were tested on

the Staffordshire and Worcestershire Canal at Coven, near Three

Hammers Farm. The 102 c.c. version was also tested on the River

Severn. The 340 c.c. model was tested on the River Severn, near

Lincoln Weir, Holt Fleet, Worcestershire. The engines were

tested by G. E. Greenwood (son of John Greenwood), and F. W.

Matthews. |

|

In 1932 only minor changes

were made to the models. New detachable and interchangeable wheels

were fitted to all models along with a 4-speed constant mesh

gearbox. Sales continued to fall and more economies were introduced

at the works. Most of the spares were sold off

In a further attempt to

reduce manufacturing costs, the 'Lion' was revamped with a detachable

cylinder head, and the Model 90 only produced in small numbers,

because it was expensive to build, as much of the machine was hand

fitted. The Model 10 was dropped, and the old 350 c.c. Model 8

reintroduced.

John Greenwood, known in the

works as 'Cherry' Greenwood because of his red nose, retired in

April 1934. As chief designer he had been the leading light behind

the Sunbeam designs,

Sales were still falling and

a re-assessment of the cycle and motorcycle production began at the works.

By the summer of 1934 motorcycle sales had greatly declined, but

bicycle sales had doubled, so more emphasis would be placed on

bicycle production. Around the same time it was decided to greatly

increase, and fully mechanise radiator production. As a result, many

of the buildings in the factory yard were demolished and replaced in

August and September by a range of modern assembly bays.

The

writing was now on the wall for the cycle and motorcycle part of the

business. |

|

R. J. Cook's Model 8 from 1935. |

At the 1934 Motor Cycle

Show, Sunbeam introduced the 'High Camshaft' Model 16. It was

designed by George Stephenson and had a duplex cradle frame, Burman

gearbox, and powered by a

249 c.c. engine. It sold for £49.10s and was

in production for about 12 months. Unfortunately sales of the

machine were not good, due to competition from other manufacturers,

particularly Velocette.

The 1934 catalogue featured

the 493 c.c. overhead valve Model 95, a top of the range machine that

sold for £95.10s and the

246 c.c. overhead valve 'Little 95' that sold

for £69.10s. There were also the 500 c.c. and 600 c.c. 'Lion Longstroke'

machines, the

250 c.c. overhead valve 'Longstroke', and the 350 c.c.

Model 8. The 1935

catalogue featured much the same range of machines as in the

previous year, but all at greatly reduced prices. |

|

Sunbeam bicycles and motorcycles were still

in the doldrums and so ICI started to look at selling their two wheeled

subsidiary. On the motorcycle side there was not too much to sell.

ICI wanted to keep the factory, for which they had other work.

There were no groundbreaking machines on the drawing board, no large

order books, and not even a production line, production lines had

never been quite the thing at Sunbeamland and the factory was not

even designed for it.

In

most years, only around 35 motorcycles were built each week. The

best year for sales was 1930 when production briefly peaked at

around 50 motorcycles a week. Although bicycles were made in larger

quantities, only 2,000 to 3,000 were made in a year, at the height

of production.

An advert from the early 1930s.

Motorcycles were always hand-built on a bench, production techniques

never improved with time. This was quite a contrast to A.J.S. which

used to be based at Graiseley Hill, where the latest machinery and

production techniques were in use, and 20,000 to 25,000 machines

were built in a good year. Because A.J.S. parts were accurately

machined, they were easily replaced when necessary. Sunbeam spares

still had to be hand-fitted, which could involve filing, or

re-drilling holes to a suitable size.

The same range of machines

remained in production in 1936 with two major innovations. All

machines now used the new duplex cradle frame and several models had

larger, improved brake drums.

During 1936 ICI continued to look for a buyer

for Sunbeam bicycles and motorcycles, and clearly caught the

attention of the Collier Brothers who ran Associated Motorcycles (AMC).

Walter Iliff, Sunbeam's Company Secretary was blissfully unaware of

this when he offered motorcycle sporting personality, George Rowley

of A.J.S. the job of Sales Manager and rider. A.J.S. had been

acquired by the Collier Brothers in 1931 and was now based at

Plumstead. George accepted the job and returned to Plumstead to

inform his employers of the situation. On his return he was told in

secrecy that AMC were about to acquire Sunbeam. He instantly wrote

to Iliff stating that he could not accept the job because he had to

give 6 months notice to AMC. This must have been quite embarrassing

for Iliff because he had already notified the press about George's

appointment.

The sale finally took place in August 1937.

On the afternoon of the sale, George arrived at Sunbeamland with an

AMC Director, the AMC Production Engineer, and the AMC Paintshop

Manager. They were clearly shocked when they looked around the

factory and saw the antiquated production techniques. None of the

machinery was of use, it was extremely old and worn-out. They

decided to transfer the large stock of components to their London

factory, along with the design data, and drawings etc. Everything

else, including the machinery, was scrapped, and the factory records

destroyed. AMC had however acquired the

customer's goodwill, the brand name, and the

dealer network. Two new companies were formed, Sunbeam Bicycles Limited,

and Sunbeam Motor Cycles Limited, and production began at Plumstead.

ICI absorbed the whole of

the cycle and motorcycle workforce into large-scale radiator

production, which was essential to secure the future of the factory.

Epilogue

Today original Sunbeam

motorcycles remain popular, and many of them are preserved

around the world. They are not only preserved, but regularly used in

rallies and vintage events, and still prove to be reliable. Although

Sunbeam got off to a slow start with motorcycle production, they

outlived most of their local rivals. When production ended in 1937,

only one of the other early Wolverhampton motorcycle manufacturers,

Wolf, was still building machines.

Sunbeamland, as it was several years ago.

|

|

|

|

|

|

| Return to The

Golden Years |

|

Return to the

beginning |

|

Proceed to

Sunbeamland |

|