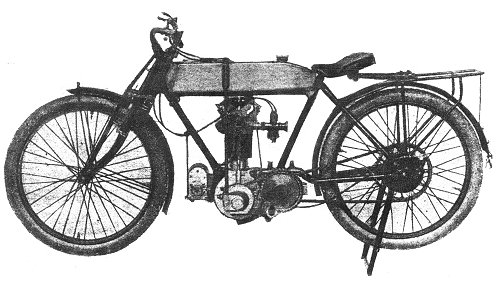

2¾hp.

Machines for the 1920 Isle of Man T.T.

An article from 'Motor Cycling', 19th May, 1920:

2¾hp.

Racers Develop 10hp.

Full details of high

efficiency junior T.T. machinesThe Stevens brothers, than

whom few people in the motorcycle trade have more experience

in engine building, have produced an extremely efficient

2¾hp. racer for this year's Tourist Trophy. One machine will

be ridden in the senior event, and six in the junior, the

riders being Eric Williams (who will also ride a Sunbeam in

the senior), Howard Davies, Bert Haddock, Harris, Harold

Heath, and O. Wade.

The A.J.S. racer is a

four-speed machine, two sprockets of different size being

mounted on the engine shaft, and driving thence to a double

sprocket machined out of the solid on the countershaft,

where an ordinary two-speed gear is fitted. The latter is

controlled by a lever mounted on the offside of the tank,

whilst the engine-shaft gear, which is changed by clutching

up either sprocket, by means of internally cut dogs, with

the engine shaft, is operated through a rod and Bowden wire

arrangement down the right handlebar.

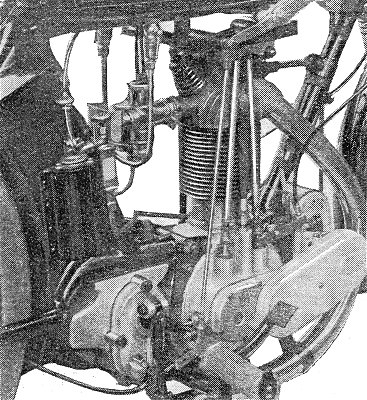

The T.T. A.J.S. simply

bristles with innovations. The new type of gear is

shown in

this view, as is the unique method of saddle springing. |

At present the gear ratios

obtainable are 4⅝, 5½, 7¼, and 8½ to 1, though these may be

modified later after practice in the Isle of Man.

The top

gear is used down long slopes with a view to saving the

engine, which would otherwise be turning over at a terrific

speed.

|

An astounding r.p.m.

has been obtained, and 10hp.

developed by the dynamometer

test by the use of very light

working parts, a very high

compression, and large overhead

valves set at an angle of 45

degrees to each other.

A single

ring drilled steel piston is used in preference to an

aluminium one, as the latter type broke up when tested at Brooklands. The piston is machined out of a solid bar of

steel, as are the flywheels. The connecting rod is a

wonderful piece of work, being machined all over, and as

light as it is possible to make it without risk of fracture.

|

A detachable combustion head

with large and smoothly-polished surface and ports, carries

the inlet and exhaust valves, the exhaust port being a good

deal larger than the inlet.

The cylinder head is held down

by a metal strap, which is anchored in the crankcase and

provides a very neat, light and strong fixing.

The overhead

rocker arms and their supports are all made of the highest

grade steel, the arms being operated by hollow tappet rods.

The compression used is 5½ atmospheres. Some trouble has been

experienced in discovering a sparking plug, which will stand

up to the work, but the Cooke plug has now been adopted

after prolonged tests.

The cylinder, like the head, is made

of cast iron. It is machined inside and out, the radiating

fins being a particularly fine piece of work. |

| The tank holds two gallons

of petrol and is provided with extra large filler caps. The

oil filler communicates with its tank, which is clipped to

the rear down tube and holds half a gallon of oil, via a

large passageway, and is arranged thus to facilitate

filling, the oil being pumped into the tank by the rider

himself at the depot.

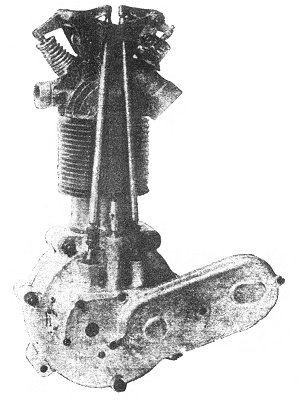

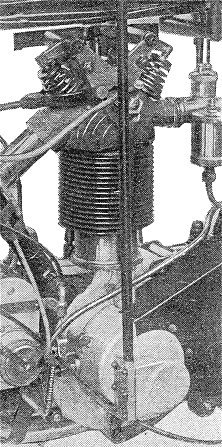

The two pictures show the

novel construction of the engine. The placing of the valves

at an angle in the head enables those of large diameter

to be used. The top picture also shows the two-speed

countershaft gear which is employed conjointly with an

Enfield type of gear. |

|

|

|

|

An article from the

'Motor Cycle', 10th June, 1920:

A.J.S.

Machines for the T.T.

Four-speed gears applied to

sturdy machines having high efficiency single-cylinder

enginesConsiderable interest will

be taken in A.J.S. machines, which besides defending their

title in the junior race next Tuesday are the only 350c.c.

engines entered for the senior event.

Frame, gearbox, forks, and

brakes are A.J.S. standard practice, but the engine and

certain features of the transmission are new. The

single-cylinder engine has a bore and stroke of 74 x 81 mm

respectively. To all intents and purposes the crank case is

standard, but steel flywheels are used and the cast iron

cylinder has a detachable hemispherical head in which

overhead valves are mounted inclined from the centre line at

approximately 45 degrees.

|

|

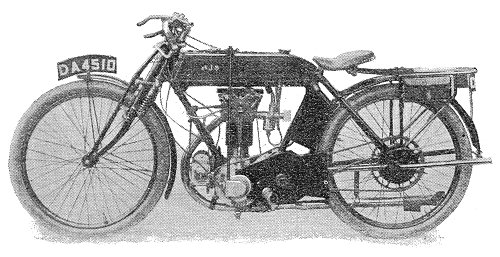

Driving side of the A.J.S.

which will defend the junior trophy.

|

These valves are operated

through standard timing gear and long push rods, overhead

rockers being carried in brackets bolted to the head.

The

fixing of the cylinder head is unusual and very ingenious,

as it is held down by a flexible steel strap passing over

the head of the engine and tightened by turnbuckles on

either side of the crank case. |

| Unorthodox Transmission

A very light steel piston is employed having two

rings at the top and a series of oil grooves,

the lower part of the skirt is copiously

drilled.

The transmission

from the engine shaft to the gearbox is somewhat

unusual, two equal sized sprockets are machined

on the clutch ring, and mounted loosely on an

extension of the crankshaft are two sprockets

which differ slightly in size.

Either of these

sprockets may be dogged to the shaft at will, a

control being operated from the handle bar.

When the smaller

of these sprockets is being utilised for the

drive, the normal high and low gear are obtained

by means of the countershaft gearbox, but the

larger sprocket can be used for long descents,

and gives slightly higher ratios so as to

prevent over-running of the engine. |

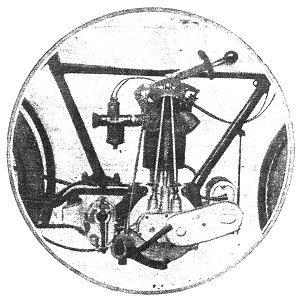

The cylinder head of the

A.J.S. is held down by a steel

strap, and oil is supplied by

a handle-bar controlled

pump from a tank behind the saddle

tube. |

Driving side of the T.T.

A.J.S., showing the housing for the engine shaft gear and

the inclined overhead valves. |

The saddle tank contains

two gallons of petrol, and the entire oil supply is carried

in a tank behind the saddle tube. A somewhat unusual method

of filling this tank is employed, since a large diameter

pipe is carried upwards through the petrol tank so as to

bring the filler cap into a normal and easily accessible

position. Lubrication is effected by a

spring pump controlled from the handle bar, the flow being

regulated by a sight feed drip. It is just possible however,

that this drip will not be used during the race.

From the illustrations, it

will be noticed that the cylinder is stayed to the front

down tube. The machine is fitted with a Brooks saddle, Amac

carburettor, Hans Renold chains, Dunlop tyres, and

Thomson-Bennett large size magneto.

It is a most workmanlike

mount, which has been designed rather with the idea of a

high efficiency machine which will stand up to the work,

than with the idea of saving weight.

A Sporting Chance

There is no doubt that the

A.J.S. stands an excellent chance of retaining its title

since there are few machines which have been so thoughtfully

designed and well constructed. It is unfortunate, therefore,

that T. H. Haddock and N. C. Heath, two of the T.T. riders

of this model, should have suffered accidents during

preliminary practice. Whether these accidents will prevent

their riding in the race is not certain, but we understand

the A.J.S. firm have other good riders in reserve.

|

| That one of these machines

has been entered in the senior event gives the A.J.S. a

sporting chance of winning both events; in any case, its

performance in competition with machines of 30% larger

capacity will be watched with great interest. |

|

|

Return to the

previous page |

|