|

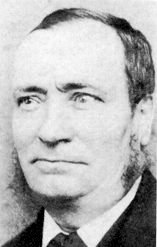

Henry Clarke |

Henry Clarke, a skilled wheelwright and

blacksmith joined the 38th Foot Regiment in

1855, at the outbreak of the Crimean War. He was

wounded in the attack on Redan, and subsequently

discharged. On making his way home via Paris, he

saw his first bicycles. These would have been

hobby horses with wooden wheels, which were very

similar to the carriage wheels that Henry was

familiar with. He realised that he could easily

make this type of wheel himself and so he made

contact with some of the French manufacturers

who were interested in his skills. When he

returned to Wolverhampton he set up the 'Temple

Street Wheel Company' to make all kinds of

wooden wheels for export to France, including

some for velocipedes. At around the same time

he married Harriet Powney from Wombourne and

they had six daughters and five sons. |

|

In the 1861 census the

family is listed as living at Baptist End Lane,

Dudley. Henry Stephen Clarke, aged 28 was born

in Pattingham, and was a Chelsea Pensioner and a

Wheelwright. His wife Harriet, age 25 was born

in Wombourne. Their children were Thomas Clarke,

aged 4, born in Wombourne, George Edward Clarke,

aged 4, born Wombourne, and Sarah A. Clarke,

aged 3, born in Netherton.

Their other children were

Henry, born in 1863, Elizabeth, born in 1865,

William, born in 1867, Jane, born in 1869,

Fanny, born in 1871, John, born in 1875,

Harriet, born in 1878, and Emma, born in 1880.

By 1863 the family had moved to No. 2, Court,

Darlington-street, Wolverhampton.

In 1887 George Edward

Clarke's son died under tragic circumstances, as

can be read in the following newspaper report:

Death of his son. 'An

inquest was held Yesterday, at the Newmarket

Inn, Cleveland Road, Wolverhampton, touching the

death of Henry Stephen Clarke, 4½,

son of George Edward Clarke, blacksmith, Great

Hampton Street. The child was, on Thursday

morning, in the kitchen with a sister eight

years old, when he reached some matches from a

chimney, and some of them being struck, his

nightshirt caught fire. The mother extinguished

the flames with a woollen shawl, but not before

the child had sustained severe burns, from the

effects of which he died in the hospital two

days afterwards. - A verdict of "Accidental

death" was returned. |

| Being a skilled blacksmith he soon picked up

the necessary skills to build complete bicycles

and decided to manufacture them himself. In

1868 he founded the 'Cogent Cycle Company' in

Darlington Street, and was joined by his five

sons; Tom, George, William, Jack, and Henry. The

first Cogent machines appeared in 1869 and sold

extremely well.

By 1877 'Cogent Penny Farthings' were selling

at prices from £8 to £10 and the company was

very successfully producing many different

models. Hubs were made in two halves and when

built-up secured the spokes, and rounded case

hardened cone bearings helped to reduce

friction. |

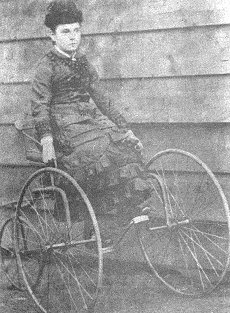

| Bessie

Clarke riding an early Cogent

tricycle in about 1870. Courtesy of

the late Jim Boulton. |

|

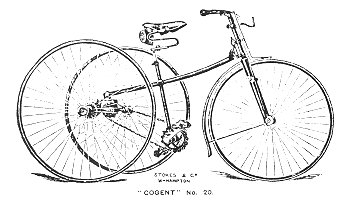

| A short

description from "Bicycles of the Year 1877"

by Harry Hewitt Griffin: "The

Cogent.- Henry Clarke, Cogent Bicycle Works,

Darlington Street, Wolverhampton. In days of

bone shakers Henry Clarke was well known as

a maker, and he cannot fail to have gained

great experience as to how a bicycle ought

to be built.

An improved form of rounded

cone bearing is adopted, which appears to be

superior to the ordinary; the working parts

being of case hardened steel, friction is

therefore greatly reduced; the hub is double

(something like Deacon's), and put on in

halves, in which the spokes are firmly

secured. Small good rubber pedals on flat

cranks are used, and the Stanley head is

employed. The handles are low and in front

of the neck. The spring is of a good shape

and very pliable. A 50in. machine weighs

about 44lb. Hollow backbones are in every

case employed. The machine is finished half

bright, and will be found a very fair all

round bicycle. The Spider is made at £2

less." |

|

| |

|

|

View the 1883 Cogent catalogue |

|

| |

|

|

An advert from 1877.

| The Cogent

No. 20 tricycle from 1887. Courtesy

of the late Jim Boulton. |

|

The company also produced a number of

tricycles.

The 'Cogent' No.20 of 1887, sold for

£15.10s.0d. It had ball bearings, a large front

wheel to reduce vibration, and a hollow steel

frame, part plated with an enamel finish. |

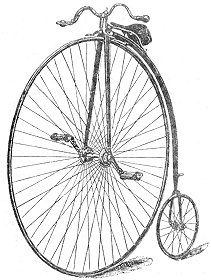

| The 'Cogent' No.5 high wheeler had seven

eighths of an inch, and three quarters of an

inch non-slipping tyres. The wheels had Crescent

rims, and 60 and 20, No.11 direct spokes.

The

back wheel was 16 inches in diameter, and the

large wheel had four and a quarter inch G.M.

Hubs, and a ten and a quarter inch axle.

The

bicycle had rat-trap coned pedals, and the

cranks had a throw of five and a quarter

inches. The machine cost £4.10s.0d. |

| The Cogent

No. 5 ordinary from 1887. Courtesy

of the late Jim Boulton. |

|

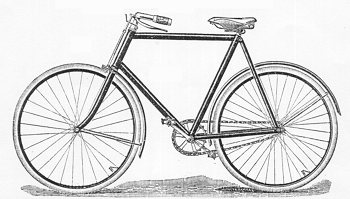

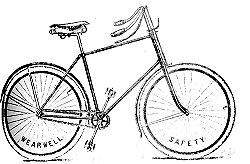

| The 'Gent's Popular' had a weldless

steel tube frame, 28inch wheels, rubber or

rat trap pedals and was finished in black

enamel. The machine was priced at £5.17s.6d. |

The Cogent Gent's Popular. Courtesy of

the late Jim Boulton. |

|

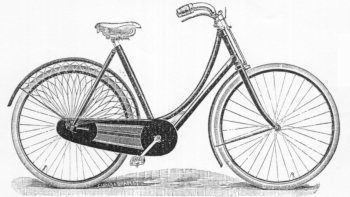

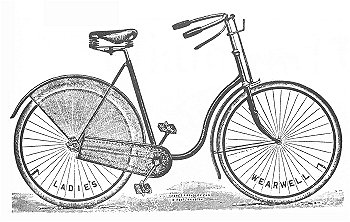

The Cogent Ladies' Popular. Courtesy of

the late Jim Boulton. |

The Ladies' Popular' had a weldless

steel tube frame, 26inch wheels and was

finished in black enamel. The machine was

priced at £6.5s.0d. |

| The following

is a short description of the Cogent No.

10 from "Bicycles & Tricycles of the

Year 1889" by Harry Hewitt Griffin:

"The Cogent No. 10 Dwarf Safety Roadster

(H. Clarke's Executors, Darlington

Street, Wolverhampton). The framing is

composed of strong double tubing, with

extra long centres; the chain adjustment

is effected by drawing forward by a set

screw on the slotted fork end. The curve

of the front forks brings the handles

well back. The machine has no striking

peculiarity, but is well and reliably

made, and is to be depended on. It is

finished with all the usual details,

including direct plunger brake, and with

balls all parts, etc. The price is

£16.10s." |

|

Wearwell's

works at 46 Darlington Street. |

| In the 1881 census Henry Clarke is

listed as living at Darlington Street, Court

2 with his wife Harriet, sons Henry,

William, and John; and daughters Elizabeth,

Jane, Fanny, Harriet, and Emma. His

occupation is given as a bicycle maker

employing 3 men and one boy. Presumably his

other sons, Tom and George, had left home by

this time. Henry Clarke senior died in

1889 at the age of 56, and one of his sons took over the

running of the business. This appears to have

been unacceptable to the other

brothers, and so Joseph Parker took over for the

executors. This resulted in Tom Clarke

leaving for Manchester, where he set up the

Express Cycle Company, while William, Jack,

Henry and George founded Wearwell.

An advert from 1892.

William became Managing Director, and the works

were situated at 46 Darlington Street, a stone's

throw from Cogent, which eventually went into

liquidation. William Married Agnes Ann Pickard

and they had three children: Elsie Elizabeth

Clarke; Henry Steve Clarke; and Albert Clarke.

By 1911 they were living at 6B Oaks Crescent,

Wolverhampton: with William's father-in-law John

Pickard, and a servant. It seems that Cogent ran for at

least ten

years after the formation of Wearwell,

trading as Henry Clarke's

Exors. This can be seen from the date on the

poster below. |

|

The 1893 Wearwell tricycle. Courtesy of

the late

Jim Boulton. |

Wearwell listed 9 Models in 1893, including

the standard cross frame safety bicycle, which

sold for £10 with solid tyres, or £10.10s.0d

with cushion tyres. There was also a tricycle

that cost £23 with solid tyres, or £29.10s.0d

with Dunlop pneumatics. The most expensive

machine, the model 'A' had a double tubed frame

and was claimed to be the strongest on the

market. The bicycle included ball bearing hubs,

a Reynolds Roller Chain and sold for £18 with

solid tyres, or £23.10s with pneumatic tyres. |

An advert from 1893.

| |

|

View the 1893

Wearwell catalogue |

|

|

The

following description of the company is from the

"Illustrated Towns of England Business Review of

Wolverhampton" from 1897:

Henry

Clarke's Exors., "Cogent" Cycle Works. A

firm that has gained distinction in the cycle

trade in Wolverhampton is that of Henry Clarke's

Exors., widely known as the Cogent Cycle Works.

The enterprise was founded in 1868, and has had

a career of prosperity, and the evolution of the

cycle from the old bone-shaker to the splendid

machines now in the market, has been due to such

enterprise and inventive skill as has

characterized this firm.

We may

state that the year 1896 proved one of

unprecedented success for this firm, the demand

for their machines being considerably in excess

over former years, in fact, the resources of the

establishment were frequently taxed to meet the

increased trade. In consideration of this

expansion, additions in plant, machinery, and

apparatus have been made and also extensions in

the factories to enable the firm to execute the

anticipated greater demand. The works are

prominently situated and splendidly equipped

with the best improved machinery and appliances.

The

productions are notable for elegance of design,

quality of material, superior workmanship and

finish; while prices are consistently low, in

fact, this firm prides it upon its ability to

supply a machine of unsurpassed excellence at

the lowest possible price. They are built with

the celebrated seamless steel tubes, the

bearings are made from the most reliable steel,

and the gearing and fittings throughout are of

the finest quality. Either racers or roadsters,

for ladies, gentlemen, or youths are

manufactured upon the most scientifical

principles and improved construction. For

specifications and prices an illustrated

catalogue may be obtained from the firm.

The

Cogent cycles have won golden opinions from the

most competent judges and experts, testimonials

being received from all quarters as to their

special merits. An extensive export trade is

done, whilst in the home markets the Cogent

cycles are duly appreciated. An adequate staff

of experienced artisans finds constant

employment, and no efforts are spared by Mr. J.

Parker, the manager, to enhance the reputation

of the firm. |

William Clarke,

Managing Director of Wearwell Cycles.

Courtesy of the late Jim Boulton. |

|

From the 1893 catalogue.

| Sales continued to grow and the

company soon became one of the most important

cycle manufacturers in the town. In 1899

William Clarke had the idea of producing powered

vehicles. He formed the Wearwell Motor Carriage

Company, and opened new premises in Pountney

Street on the site that is now occupied by J. W.

Braithwaite & Son Ltd, bookbinders.

They produced a 4 wheeled, powered vehicle

which had two Butler, two and a quarter horse

power engines, mounted side by side. It was not

generally liked. |

|

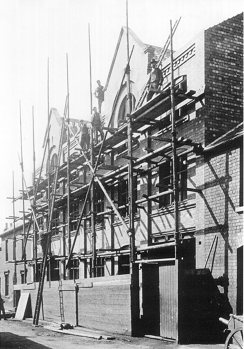

This photograph, which

came from Albert Clarke's collection, was given

to us by Geoff Stevens. It shows a small part of

the Wearwell works in Pountney Street during

construction. The

street was originally made up of mainly housing,

which was slowly replaced by factories as the

area became industrialised.

The Wearwell works

eventually covered much of the site that was

later occupied by The Star Engineering Company,

and eventually Braithwaites. It is now a banqueting

suite. The photograph shows

the original building nearing completion. The

houses on each side would eventually disappear

as the works were extended. |

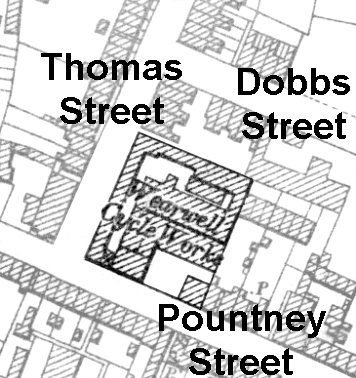

| The location

of Wearwell's factory on the corner of

Pountney Street and Thomas Street.

The site had

previously been occupied by Lion Iron

Works and was advertised for sale by

Nock and Joseland in 1881. |

|

| The

engraving on the company's

letterhead gives a good

impression of the large area

covered by the factory. |

|

A letterhead from 1907.

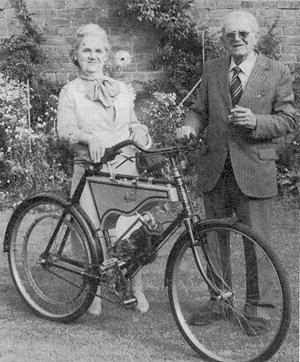

| William saw the early Stevens brothers'

motorised bicycle and realised that this was the

way forward. The company already had links with

the Stevens Motor Manufacturing Company, who

supplied spokes and screws for the bicycles.

An agreement was entered with Stevens and a

contract drawn-up. Stevens agreed to supply a

minimum number of engines each week, which were

fitted to heavy duty bicycles.

The new motorcycles were called

Wearwell-Stevens machines, and sales were very

good.

See the motorcycle section for more details. |

Mr. and Mrs. Albert Clarke with a 1901 Wearwell-Stevens

motorcyle.

Photo courtesy of the late Geoff Stevens. |

|

|

The model B from 1893.

The basic bicycle with solid tyres weighed 38lbs

and sold for £16. Dunlop pneumatic tyres were £5

extra and a Carter's gear case could be fitted

for another £3.

Courtesy of the late Jim Boulton.

|

| A ladies cycle from

the 1893 Wearwell catalogue.

Courtesy of the late Jim Boulton. |

|

| An advert from 1904. |

|

|

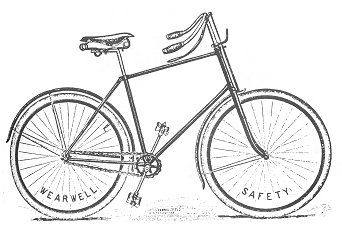

The Wearwell Road Racer. |

By 1905 the company was displaying about 15

models. There was a 7 guinea gentleman's

roadster machine, with Crabbe back and front

brakes, Micrometer, Hyde, or Crabbe free-wheel,

Brampton's chain and Clincher B, or Warwick

tyres. The machine was finished in black enamel

and gold lining. The ladies version cost

£7.12s.6d. There was also a path racing machine

weighing 19 pounds and a road racer which

weighed 21 and a half pounds. |

| The model 'B' weighed

38 pounds, and sold for £16 with solid tyres.

Dunlop pneumatics were an extra £5 and a

Carter's Gear Case cost another £3. |

|

|

By 1908 about 500 machines were produced

each week, many of which were exported. One of

the main importers was Holland, from where

orders of up to 10,000 cycles were not uncommon,

with machines being sold for as little as 27

shillings each. At the same time the company

produced about 20 Wolf motorcycles per week.

Another very different product were 4 wheeled

and 2 wheeled roller skates. At the time roller

skating was extremely popular and most towns had

at least one skating rink. Wearwell designed a

skate with rubber shock absorbers and about 500

pairs a week were sold. 2 wheeled versions were

also widely used and Wearwell produced a version

of their own.

|

| Disaster struck in 1909 when it was

discovered that the Company Secretary, Mr. King,

had been using the company's money to gamble at

pool in a local public house. A large sum of

money had disappeared, which led to the company

going into liquidation in 1911. Mr. King tried

to commit suicide, but William Clarke did not

bring any criminal charges against him, because

he discovered that one of his brothers was also

involved. |

| The

company manufactured and distributed Pickard's Patent Lining

Apparatus, as can be seen from this advert from

1917.

|

Read about

Pickard's

lining apparatus |

|

|

|

An advert from 1921. Courtesy of the late Jim Boulton. |

After the liquidation, William Clarke

purchased the ailing Wulfruna Cycle Company from

John Barratt. He revitalised the business and

reintroduced the Wearwell and Wolf names at

Eagle works in Great Brickkiln Street. William

died in 1922 and the business was sold to Theo

Waine in 1928. |

| Some members of the Clarke family continued

in the motorcycle business. Jack joined the

Stevens Company in 1911 and became manager, and

Albert, who was Henry's grandson joined H.R.D in

1925 as works manager, when one of their

machines won the Isle of Man T.T. |

| Read about the

Wulfruna Cycle Company |

|

|

The Old Wulfruna bicycle works in Great

Brickkiln Street. |

|

Joseph Waine & Co. Ltd, were general lock, latch & bolt

makers, and brass and iron founders at Imperial Works, Wood Street,

Willenhall. Joseph had three sons, John Vincent Waine, G. A. Waine and

Horace T. Waine.

John Vincent Waine, and his brother G. A. Waine, started the

Vulcan Manufacturing Company at Blackheath, Birmingham, in about 1910.

The company manufactured Heel Tips, Toe Plates and had the most up to date

machinery in the world. The factory turned out 288,000 pairs of heels per

week, under their Vulcan brand name. The company specialised in a

number of products including No. 0 and 1 York heels, 21B heels, mule & horse

shoes for the Indian, Turkish, African and South American markets, and

japanned and galvanised door bolts. A large number of other products were

produced including the following:

Brass, chromium-plated and special finishes, stainless

steel, garage bolts, cabinet bolts, shelf brackets, aluminium door and gate

latches, casement stays and fasteners, hasps and staples, hinges, brass and

steel gate and tee, gutter brackets, swivel ties, tinned angle brackets,

rim, dead and mortice locks, latches, padlocks, stamped brassware and

household soldering sets.

|

|

The works covered over an acre. Extensive trade

was done with the War Office, the Army and in various parts of

Europe. Horace T. Waine was also involved in the business, and

due to his international travels the products were also sold in

Japan, Burma and Egypt. The company also had an establishment in

the Potteries.

In 1913 the Directors decided to move the three

factories to one site to improve the company's efficiency. In

June a large disused works was purchased in Colliery Road,

Wolverhampton and the three factories were combined under one

roof, and called the New Griffin Works. |

The New Griffin Works today. They are

occupied by hydraulic equipment manufacturer

Hydrofix. All that is left was originally part

of the Vulcan Manufacturing Company. The

Wearwell works have gone. |

|

1914 Whitakers Red

Book, Who's Who in Business:

Joseph Waine & Co.,

Ltd., Merchants and Manufacturers, with

which are amalgamated Luke Lawrence &

Co., Mills & Green, Green Brothers,

Isaac Waine & Co., David Furguson & Co.,

John Arnold & Co., The Brook Tile Co.,

Lincoln Pottery, Burslem; New Griffin

Works, Horsoley Fields, Wolverhampton.

Hours of Business: 9.30 a.m. to 5 p.m.

Established in 1880 by Joseph Waine.

Continued by G. A. Waine, J. Vincent

Waine, and H. T. Waine.

Incorporated as a

Limited Company in 1909. Directors: G.

A. Waine (Managing Director), J. V.

Waine, H. T. Waine. Of the firms

amalgamated, Messrs. John Arnold & Co.

has been established 100 years, and is

under stood to be the oldest firm in the

Brass Lock trade.

Staff: Total of

amalgamated firms, 100 hands, and

Lincoln Pottery employ eighty hands.

Depots and Branches: At Bombay,

Calcutta, Madras, Colombo, Karachi, Hong

Kong, Shanghai, Batavia, Singapore, &c.

Specialities: Locks of all descriptions,

Door Bolts, Safes, Hinges, Rabbit Traps,

Combs, Floor Tiles, Brass Foundry, Tools

and General Hardware, &c. Patents:

Numerous. Connection: United Kingdom,

Foreign, Colonial, Egypt, Holland,

France, South Africa, Canada, Ceylon,

India, Java, China, Japan, Burma,

Australia, New Zealand, &c. Telephone:

No. 521 Wolverhampton. Bankers: Lloyds

Bank Limited. |

|

The works back on to the canal where

barges could be loaded and unloaded. |

In 1928, Theo Waine and his brother Mr. G.

A.Waine, took over the Wearwell Cycle Co. Ltd.

from the liquidators of the Wulfruna Engineering

Co. Ltd.

Their sons, H. V. Waine and T. A. Waine were

issued with one ordinary share each, and were

appointed directors at the first shareholders

meeting, which took place at the New Griffin

Works.

The new company was registered as the

Wearwell Cycle Co. (1928) Ltd. |

| Initial finance was provided by the issue of

£4,000 worth of £100, 7% debentures which were

the responsibility of H. V. Waine, who had also

been appointed company secretary. At a second

meeting shortly afterwards it was resolved to

purchase from the Vulcan Manufacturing Co.

(Wolverhampton) Ltd, the plant, tools and

stock-in-trade of the cycle manufacturing side

of their business, for £10,209.16s.5d. |

| A full range of machines were on offer in

1929 including tradesmen's cycles, juveniles,

scooters, and the 'Duplex' with a distinctive

cross frame consisting of a thin top tube

running from the seat lug to the fork crown,

with twin tubes running from the steering head

to the rear hub.

The very strong frame weighed only about one

pound more than a conventional diamond frame. |

The Wearwell stand at the

1934 motor cycle show. |

| The 'Le Grand' road racer had a double

cog gear hub, 2 calliper brakes and a very

attractive selling price of £5. The top

model the 'Golden Roadster' had a 3 speed

hub, oil bath gear case and sold for

£6.17s.6d. The following year the machines

were on display at the 1930 Olympia Show and

again at the 1931 show with the addition of

the new 'Schneider' sports machine. It had

Endrick rims, 'No Weight' mud guards,

Pelissier brakes and a swan neck handlebar

stem. The new machine sold for £7.10s.0d. A

cheaper version called the 'Wanderer' was

also on offer at £6. |

|

The company's stand at

the 1931 Olympia Show. |

|

The top of a Vulcan Manufacturing Co.

order showing

the company's letterhead. Courtesy of Peter Waine. |

|

The Vulcan Manufacturing Co. (Wolverhampton)

Ltd applied for 6,000 ordinary shares of £l each

to be issued for cash and in 1931 the factory

was expanded and the production of 'Wolf' motor

cycles began. The company prospered and sales

continued to increase, though the works were

damaged by fire. In March 1932 fire fighters

battled for eight hours to control the fire

which caused £10,000 worth of damage. |

| Mr.

H. V.Waine, a keen motorcyclist, was

responsible for the design and production of

both motor cycles and cycles, while Mr. T.

A. Waine was responsible for sales. In July

1932, Mr. G. A.Waine, and Mr. J. V. Waine of

the Vulcan Manufacturing Co. were each

issued with one share each, and appointed

advisors to the company. Waine Eastern

Agencies of Singapore, were appointed sole

selling agents for India, Ceylon, Burma, Straits

Settlements, Siam and China. Other agents

elsewhere were subsequently appointed. |

The 1949

'Tradesmen's Carrier' costing

£14.6s.2d. |

|

An advert from 1950. |

A considerable number of cycles were

exported to India, and post war Wearwell (India) Ltd, a wholly Indian owned

company, manufactured cycles with technical

support from the Wolverhampton company,

which had reverted to the title of the

Wearwell Cycle Co. Ltd. in 1933.

Motor cycle production ceased during the

war and was not restarted post-war. H. V.

Waine, who was an air raid warden during the

war, remarked one night during the blitz

that there was quite a blaze on the horizon,

only to discover it was his own factory!

The workers set-to the following day and

soon had some production restored. The

factory buildings were soon rebuilt, though

fire damaged machinery was not all cleared

away until after the end of the war.

After the war the cycle side of the business

continued to be successful with 75% of sales

going to around 38 different countries and the

company cycle team won the Tour of Britain cycle

race in 1953.

By this time the company was

employing several hundred workers. The company

also developed a toy department which made

childrens' tricycles, swings and other items.

|

| The company's bicycles were sold in many

countries including the U.S.A. The Waine

family had discussions about different

product names for different countries and

decided to use the "Vulcan" name for their

products destined for North America. The

photograph opposite shows the badge on a

Vulcan bicycle from the mid 1950s. |

Courtesy of Thomas

Collette. |

|

|

Thomas Collette's

excellent Vulcan bicycle from around 1954.

Courtesy of Thomas

Collette. |

| In 1969 the Vulcan Manufacturing company

went into voluntary liquidation, and the

goodwill was sold to Tippers, who were in the

same line of business.

The Wearwell Cycle Co. was also sold, though

production continued on a smaller scale at

Alverley, under Martin Wells, with Mr. H. V.

Waine acting as Chairman. |

The 1949

'Anglo Continental' that sold for

£16.14s.11d. |

|

|

After retirement he continued to work for

the company on a part time basis and initially

about 300 bicycles were built each week. The

business was soon sold to the Elswick-Hopper

Cycle Company and production moved to Brigg in

Humberside. Unfortunately sales started to

decline due to the recession and the company

closed. |

|

A

'Wulfruna' bicycle that was made at the New

Griffin Works in about 1957.

photo

courtesy of Peter Hällström. |

|

| I would like to thank the late Peter Waine, and

Charles V. Waine for their encouragement and

valuable assistance. |

|