H. M.

Hobson Limited,

Accuracy Works Limited,

Lucas Aerospace

| Hobsons was founded in 1903 as H M Hobson Ltd., by

Hamilton McArthur Hobson, George Cheeseman and Edward A. H. de Poorter.

It was originally an agency for selling bicycles. It was a London

based firm with registered offices at 36 Basinghall Street, EC,

works at Pelham Road, Wimbledon and, later, premises in Vauxhall

Bridge Road. |

|

H. M. Hobson.

H. M. Hobson. |

Mr. de Poorter, who seems to have been a Belgian, lead them into the

motor trade. At that time the interest in and development of motor

transport was much greater on the continent than it was here.

Hobsons took up agencies for Mathieu and Dasse cars of Belgium.

They

did not sell many and Hobsons swapped to Decauville. They imported

chassis and fitted bodies to them. Hobsons found they sold well but

Decauville gave up making them in 1909.

Hobsons then got the agency

for Delahaye cars. Hobsons imported the cars but altered them

considerably for the UK market. They also sold well. |

|

In 1907 Hobson's exhibited the Nagant-Hobson car at the Olympia Show.

Whether this was their own design or another agency deal is not clear. But

these cars also seem to have sold quite well.

Through de Poorter they obtained an agency for Pognon spark plugs. These

seem to have been recognised as clearly the best on the market and were much

pirated. They were therefore re-named Pognon Hobson. Hobsons seem to have

started with an exclusive agency for the UK but later they got worldwide

distribution rights and annual sales started to amount to more than 120,000.

Hobsons also distributed Jenatzy Tyres and the Hobson "La Perfecta" non-skid

device.

In 1908, on a visit to France in connection with the

Pognon plugs, the directors met Claudel, a French engineer who was

making a car with his own design of carburettor. The carburettor seems to

have been demonstrably superior to existing types.

|

| Hobsons got

Claudel over to England and negotiated an agency and manufacturing

deal for his carbs. At first Hobsons main business was fitting these

carburettors to existing cars, replacing inferior originals. Later

they sold them to Sunbeam, Vauxhall and other car manufacturers. |

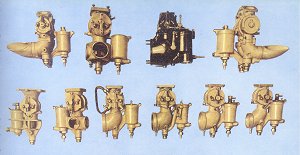

A collection of old Hobsons carburettors. |

|

The directors had a personal interest in flying and in 1909 Hobsons

advertised that they could supply Sommer's Aeroplane, for which they had,

presumably, yet another agency deal. In 1910 two of the directors fitted a

Claudel carburettor to a Wright biplane which they owned between them. They cast it

in aluminium, not the usual bronze or gunmetal, in order to save weight but

did not otherwise adapt it. This was their first venture into aircraft

carburettors.

So Hobsons started with a group of business men who had a good eye for a

good product and great skill at negotiating business deals. The company was

principally a sales organisation with a service department and a willingness

to try anything which might turn a profit. Their first big success was the

Claudel carburettors. These they imported from Claudel in France but soon they were

selling so many that Hobsons started making them in this country. Such was

the state of the art at the time that the work was given to a firm of

instrument makers.

|

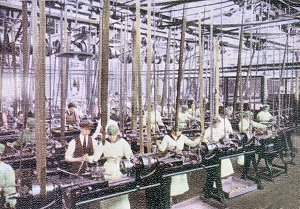

An old, heavily re-touched photo of the

original Accuracy Works.

An old, heavily re-touched photo of the

original Accuracy Works. |

In 1909 the French designer Louis Coatalen joined

Sunbeam in Wolverhampton. One of the first things he did was to

design a new engine which used the French Claudel carb.

The quantities Sunbeam needed could not be supplied by Hobsons.

But, Hobson's company history relates, "the Sunbeam company knew of

a small factory in Cousins Street which seemed suitable". |

| So a meeting was convened of Sunbeam directors

(Cureton, Coatalen, Iliff) and Hobsons (Hobson, Searight, Cheeseman,

de Poorter) "and a decision made to take over the Cousins Street

premises and form a small company, which was eventually registered

as Accuracy Works Ltd on May 9th 1911". It is not clear what part Sunbeam played in the Accuracy

company: they may have helped to finance it or they may simply have

given guarantees of orders. |

The original Accuracy Works as

they are in 2003. |

The interior of the old Accuracy Works, a

forest of drive belts. |

In 1912 James Montgomerie was appointed General Manager of

Accuracy Works and was there for nearly forty years. The

continuing success of the works is largely attributed to him.

His background is not known but he seems to have been a rough

diamond in the Edward Lisle mould. Bill Bradley, the works

foreman, said of him: "Mr. Montgomerie and me was the best of

friends. I had the sack six times a week! I once had the sack

for a fortnight - but he paid me for it". |

| At the outbreak of War in 1914 most of Accuracy staff

were sacked on the grounds that there would be no work for them

during the short duration of the war.

Hobsons then found there was a

profit to be made from a lengthy war, especially one in which the

forces were beginning to rely heavily on mechanised transport. They

expanded greatly, with Accuracy working round the clock.

Hobsons did their own development work on the Claudel

carburrettors which were used in Sunbeam-Coatalen aero engines, all

the Liberty engines from USA, and the Rolls Royce Eagle Falcon and

Hawk engines. |

A detail of the original

Accuracy Works. Its original builder and use are not known but

it was far from the basic factory design of its time. |

|

After the war the company continued its carburettor production, and

developed the Automatic Boost Control with Bristol Aero Engines. This was

fitted to the Bristol Pegasus engine, and led to the development of the

Hobson-Penn Automatic Mixture Control. From this start Hobsons finally

developed the sophisticated Master Control Injection Carburettor.

But they were still looking for new products and new opportunities. In

1919 they introduced the Hobson-Perfect Window Regulator, which was the

first wind up system for windows in cars, buses, coaches and railway

carriages etc. This seems to have been invented by Hobsons themselves and

was a market leader for decades. But it does not seem to have been made in

Wolverhampton.

In 1922 they acquired the right to make an American petrol gauge. It was

sold as the Hobson-K.S. Telegage. They developed this and adapted it to

gauges for oil pressure, water temperature, and battery water level and made

it in hydrostatic and electrical form. These gauges were widely used

throughout the British car industry and were later adapted for use in other

industries, such as the brewing, dairy and petroleum industries, to become a

major company product.

Sometime post war Hobsons decided to stop relying on the erratic M.

Claudel for design and development and engaged as consultant, and then

employed, Captain E. Dodson, who was there until his died in 1947. He seems

to have been responsible for most of the new ideas, innovations and designs.

These included the Hobson Master Control System which incorporated intricate

controls in the carburettor as one unit for maintaining engine boost

(induction) pressure and mixture strength at any pre-determined requirement

. "The first fully automatic carburettor was fitted to an Armstrong-Siddeley

Cheetah engine in the mid 1930s and so efficiently did it operate that it

was not long before the Accuracy Works were making large numbers in various

types suitable for Armstrong-Siddeley Motors, the Bristol Aeroplane Company

and later de Havilland".

In the post-war years Hobsons were associated with many car and plane

speed and endurance records and racing successes. In 1919 Alcock and Brown's

Vickers Vimy was powered by two RR Eagle engines with Hobson carburettors.

In 1927 Hobson moved all of their London operations to Acton Vale. At

that time they listed their products as: Claudel-Hobson Carburettors,

Hobson-Perfect Window Regulators, Hobson-KS Telegages, Belflex-Hobson Fabric

Spring Shackles and Engine Mountings, Hobson Sparking Plugs.

In 1935 what had been a private company was turned into a public company

called H. M. Hobson (Aircraft and Motor) Components Ltd. In effect

this was a holding company which owned:

H. M. Hobson Ltd.: basically the selling organisation for the

other two companies and makers of Hobson-K.S. Telegages and Hobson park

plugs

Floats Ltd.: who made the window regulators

Accuracy Works Ltd.: which made "the Hobson-Penn automatic mixture

control, Hobson induction pressure (boost) control, Hobson-Swan ice

eliminator, Hobson automatic ignition control, and the Hobson fuel pump and

control diaphragm" and everything made under the "exclusive licences of the

foreign patents right for Claudel-Hobson carburettors and controls".

|

|

The factory expanded back from

Cousins Street to what is now the Birmingham New Road which this

large building (date unknown) fronted on to.

Its last use was

by Yarnolds (curtain makers) who moved out of all but a small part

at the rear several years ago. |

| This view was taken from the top

of the eastern end of the original Accuracy Works, looking towards

the Birmingham New Road. It gives some impression of the size

the factory eventually became. But it also shows that the

buildings suffered the usual fate of abandoned buildings and fell

prey to vandals, undesirables and the like. |

|

|

This photo, taken from the

Birmingham New Road and looking down one side of the Accuracy Works

site towards Cousins Street, again gives an idea of the eventual

size of the works. It also shows that, as with most factories of

this size, the development tended to be piecemeal, with new

buildings being erected as need arose.

The company also owned the Integral works

in Wolverhampton.

|

| When the Second World War broke out Hobsons, who anticipated that

London would be bombed, moved all of their works out of London to

Bridgwater and Coventry and Oldham. Their premises in Coventry were

then bombed out and all the work from there was transferred to

Wolverhampton.

Their products were in enormous demand for the war effort. Most

British aircraft had Hobson equipment. The Accuracy works were

working flat out, as were several shadow factories (other companies'

factories which were turned over to war work and authorised by the

government to make other people's products). The company history

also refers to "the relatively new Hobson factory adjoining the

Stafford Road at Fordhouses" as engaging in war work. Presumably

they had acquired their Stafford Road site sometime in the mid

1930s. The old Accuracy works had been expanded far beyond the

original premises in Cousins Street as far as what became the

Birmingham New Road. But when Hobsons left those premises is not

known.

|

|