|

Bradley & Co. Ltd.

(Beldray)

Mount Pleasant, Bilston

|

|

A short account by a former employee

George Phillpott

The company's premises at Mount

Pleasant, Bilston, are locally listed as a good example of 1930s

architecture. They are now occupied by the Wolverhampton City

Council social services and the company's works lie behind them.

Starting out

The company's logo can still be seen

above the

door of their old offices. |

For many years Bradley's, trading under the

product name "Beldray", were one of the U.K. leaders in the

manufacture of domestic hollowware, with a wide range of

products. The firm was founded in 1872 by Walter Smith Bradley

and further developed by his two sons, Herman and Hector

Bradley. The trade name was an anagram of the family surname.

Eventually the company changed its name to Beldray Ltd. Their

logo was a bell on a dray - "dray" being the old word for a

wagon. |

| When I left school in December 1932, jobs were hard to come

by. I was lucky to be taken on by Bradley's and I started

there in January 1933, aged 14. When I joined the company was

owned by the two brothers, Hector and Herman, both of whom had

served as officers in the First World War.

Hector had been wounded or gassed and we seldom saw him at

the works. In fact a few years after I joined the company

he died and I remember that one of the works vans was filled

with flowers on the day of his funeral.

Herman liked fast cars. I think that in his youth he

had raced at Brooklands. He travelled to the works from

his home on the Thames in a French car, a Darracq, and although

he had a chauffeur he used to take the wheel himself when they

hit the open road (there were no motorways then).

Conditions of employment were rather different then to those

of today. This is not any criticism of Bradley's - it was

common practice among employers. They would take on school

leavers, such as myself, and when a few years later they had to

start paying them adult wages, they would sack them and take on

other juveniles. I had been at work there for several

weeks before I found out that I had been given the job from

which a very good friend had been dismissed (but there were no

recriminations).

My first job was to help to make coal scuttles. They were

called "Waterloos" because they were shaped like the hats which

soldiers wore at the Battle of Waterloo. After about twelve

months I went into the tool room as an apprentice tool maker.

This meant a drop in wages but it ensured that I would still

have a job after I reached the age of 18 and that I would have a

trade to my name. The tool room foreman was a man of most

uncertain temperament and, apparently because he frequently

referred to peoples as "proper Job's comforters", he was known

as Joey. He called everyone "Chile", in much the same way

that men today used the terms "mate" and "pal". I do

remember, however, one pearl of wisdom that he imparted to me:

"Remember this, Chile, the man who never made a mistake, never

made anything".

|

|

The company had an excellent reputation as makers of high

quality domestic wares, and the product range included dustbins,

buckets, household shovels, kettles of all sizes, watering cans

and a host of other items, including frying pans by the

thousands. Most of the products were galvanised, though some

were tinned and others, such as kettles and coalscuttles, were

black enamelled.

Some of these items we made then have now passed into history

such as the small hand bowl, with a wooden handle about 6" long,

with which the housewife would ladle the water out of the

washing tub when washing was done. Another was the mortar bowl,

a large steel receptacle shaped like a pudding basin, which had

been flattened somewhat, and about 24" in diameter. I never saw

them in use but I always understood that ladies in Africa

carried them around on their heads with goods and merchandise in

them. |

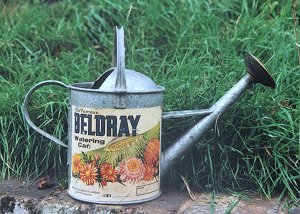

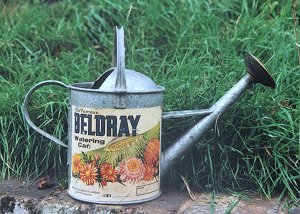

This is me holding a

watering can, which I can still remember making the tools for |

Yet another was the egg bucket, a specially designed bucket,

the purpose of which was to preserve eggs before the days of the

fridge. A substance called isinglass (which Bradley's did not

provide) was added to keep the eggs in good shape.

| This is another of

Beldray's many products: the Rapid Vacuum Ice

Cream Freezer. It was like a huge vacuum flask.

You packed ice and salt in the bottom, round the flask,

then poured your ice cream mixture into the flask at the

top. Then you left it until it froze.

The instruction book which came

with it explains that ice cream is particularly good for

you because it contains so many calories! It even

provided a list of other foods, including chocolate,

which had fewer calories and which were, therefore, not

so beneficial.

I think this device was made in

the 1920s or 30s. |

|

|

The watering can, from Reg Aston's

collection, is dated before 1950. The body is galvanised

iron and the rose is brass. With its original label it is

now a rare survivor. |

Thousands upon thousands of paint cans were made,

some bearing proprietary names such as "Walpamur".

One shop made oval tin baths and in the tool room was a

machine which I believe was most unusual.

It was a lathe made by Maud & Turner. It machined no circular

but elliptical shapes on which tools were machined to produce

the bottoms of the oval baths and oval frying pans. The rise and

fall of the revolutions of the lathe head were achieved by a

series of cams and slides. Needless to say it did not revolve

very fast. |

| But there were more arrows in the Beldray quiver than kitchen

utensils. They made a charming selection of ornamental vases,

rose bowls, cake stands and the like, from sheet copper and

brass. These were made in what was virtually a separate factory,

though within the Mount Pleasant premises. It was known to one

and all as the "Copper Side". |

| The manager of the "Copper Side" was Mr George

Freeman.

Freeman Place, off Bunkers Hill was named after him, since he

bought one of the first houses in that culde-sac, (though others

may say that it was named after his wife, Mrs Hattie Holland, a

JP and local councillor who represented the New Town Ward on the

Bilston Urban District Council).

Similarly Holland Road was named after Mr Albert Holland, the

foreman/manager of one of the large machine shops. |

This display at the Made in

Bilston Exhibition, 2002, shows many pieces of Beldray brass and

copperware and some chrome plated ware too. |

| On the copper side I remember there was a German made machine

which used to roll the patterns into the brass and copper sheet

used for vases and the like. I think it was installed just

before World War 2. It was operated by Herbert Martin. The

company was making this brass and copperware at least up until

the time I left. The manager then was George Freeman, the

foreman was Rubin Timmins and the forewoman was his wife, Floss

Timmins. The shop foreman over the spinning of bowls was George

Lee. |

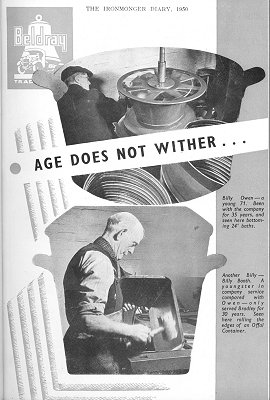

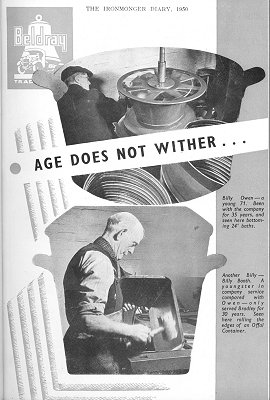

An advert from 1950, showing, at the

top, Billy Owens, then aged 71; and, at the bottom, Billy Booth.

They both symbolise the traditional craftsmanship of the

factory. |

The Despatch Department was presided over by Mr

Walter Williams and included in his staff was his elder son,

also named Walter. He had a younger son, Bert, who I believe

worked at Bradley's for a short while before moving on to fresh

fields, namely those at Wolves, Molineux, Wembley and others

further distant.

An old chap who appeared in many of Bradley's adverts was

Billy Owen. One of these adverts is shown on the right. I knew

him very well, although he was old enough to be my father. He

lived near us, in Beech Road, and we sometimes walked to work

together - before I got my first bike!

The shop in which we worked was known as Hayward's Shop, for

the simple reason that that was the foreman's name. Billy's

machine was the only piece of machinery in that shop. Everything

else was bench and hand work. In the picture he is rolling

together the body and the bottom of an oval bath tub, to make a

watertight joint and seal. (You can just make out the shape of

the bath through the slots in the plate and spindle which were

holding them in place while they revolved). |

Note that in the advert above Billy Booth's age is not mentioned.

I have been shown a letter by a descendant of his, which was sent in

response to his daughter writing to ask if Billy Booth could retire.

The reason for that was that in those days you were not entitled to a

pension but the company might grant you one if you had worked there many

years. The letter, sent in December 1953, comes from Hermon

Bradley saying "I am surprised to hear he is as old as 76" and that "he

has been a very excellent servant to the company in all ways". And

"iof he retires he will certainly get a pension and he will also get a

lump sum for the number of years he has been here ... and I certainly

agree that if it is knocking him up it is certainly time he retired".

I suppose that in all factories there were, and still are, certain

"characters". I remember one chap who worked in the galvanising shop as

a labourer and who, to put it kindly, was not very bright. The men in

the shop were very protective to him and woebetides anyone who tried to

"take the Mickey". He used to use the Market Tavern pub opposite the

Market Hall where some clever people used to amuse themselves and others

by lining up a shilling, a sixpence and a penny on the bar, then

inviting him to take one. He always took the penny, because, so they

thought, he believed it to be the most valuable because it was the

largest. Someone asked him why he didn't take the shilling since it was

worth so much more. "I know it is" he said, "but if I was to tek one o'

them they wouldn't do it again would they? They think I'm saft".

Then there was George, the works blacksmith. A man who

was very much overweight but who could swing a sledgehammer with the

best of them. It was he who told me the story of the blacksmith who was

training a new striker and told him. "I shall put the red hot iron on

the anvil and when I nod my head, you hit it as hard as you can”.

|