|

Cannon Iron Foundries Limited

Deepfields, Coseley |

|

|

The company was founded by

Edward and Stephen Sheldon in 1826, on a piece of

land, known as 'The Dowry', that been purchased from

the Turton family. John Turton gave the land to his

daughter Elizabeth in 1807. The company was

initially known as Edward & Stephen Sheldon &

Company Limited. The piece of land was ideally

located for such a business, lying alongside the

Birmingham Canal, next to many adjacent collieries.

For around 100 years, the company purchased pig iron

from the neighbouring Prioryfield Furnaces.

The opening of the Coseley

Tunnel and the completion Telford’s mainline canal

in 1838 must have greatly helped the business.

Products initially consisted of cast iron pots and

pans, which were very popular at the time.

The foundry initially covered

nearly half an acre and employed between 15 and 20

people. The products sold well and expansion

followed. Some time in the 1840s, Stephen Sheldon,

who was the junior partner, left the business,

leaving Edward solely in charge.

|

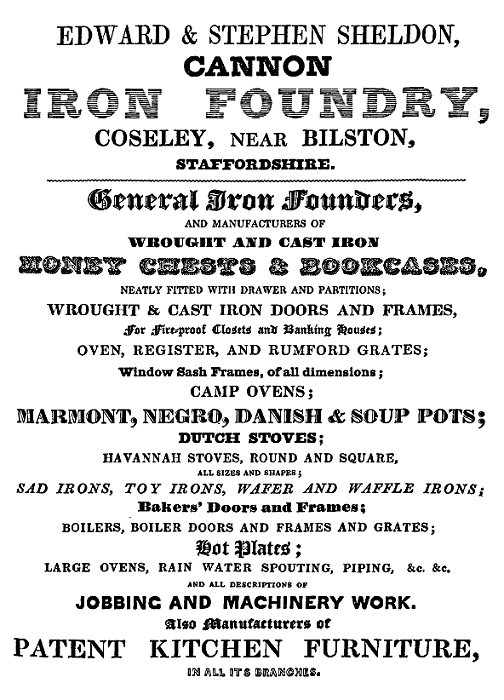

An advert from 1842.

| On 1st April, 1853, Edward died,

and the business was carried on by his sons-in-law,

William Barnett and John Hawthorne. In January 1855

the name was changed to the ‘Executors of the late

E. Sheldon’, then in June 1860, company director

William Barnett, took the decision to change the

name to E. Sheldon & Company. In May 1884 the

business became a private limited company with a

capital of £50,000 and became Cannon Hollowware &

Company Limited. The shares were held only by the

partners, who were all family members. |

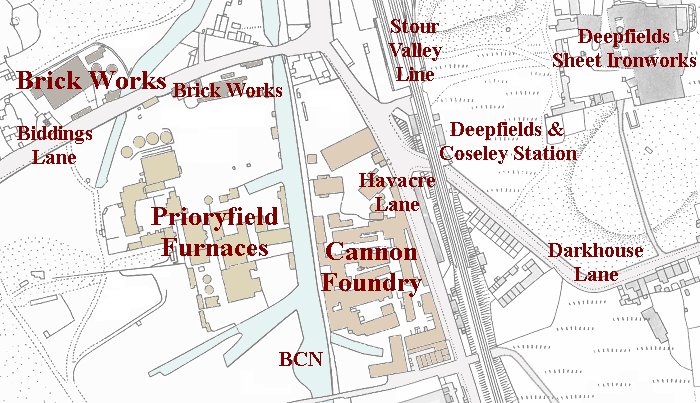

The site of the original

factory.

|

The product range was

greatly extended to include kettles, preserving

kettles, pots, saucepans, and stewpans. The

products were made in large numbers and

distributed throughout much of the world. The

products were continuously improved and many

patents were taken out. Items were given a

porcelain enamelled or a tinned finish. The

enamelled products were sold under the

‘Porceliron’ name. Saucepans were fitted with

patented hexagonal handles, known as ‘F.G.’,

meaning firm grip.

Steam-powered automatic

presses and tools were used, and the japanning

shop, where the exterior of various products was

given a japanned finish, had two tiers of drying

stoves, each holding between 400 to 500 pots and

pans. There were five floors in the warehouse,

each having a weekly output of over 5,000

saucepans alone.

In the 1840s the foundry

began to produce Cannon brand Colonial castings

that were sold in Africa, South America, the

West Indies and the Far East. The vast product

range included a wide range of cooking pots,

camp ovens, Havana stoves, baking pots, cassada

plates, rice bowls and rice pans. One of the

larger products was a huge three-legged pot with

a capacity of 140 gallons, for palm oil boiling.

It was sold to the West African market.

|

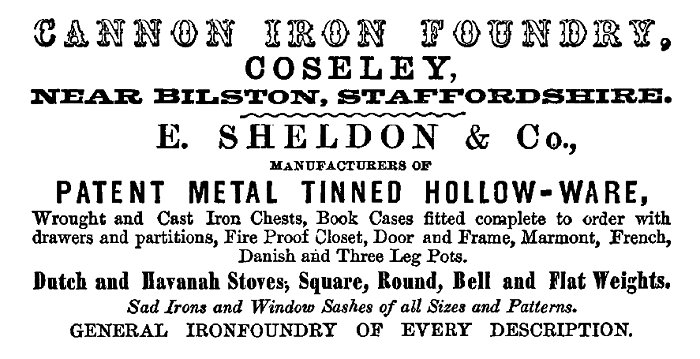

An advert from 1865.

| In 1894, the company formed its own fire

brigade, made-up of members of staff. The first

Captain of the brigade was W. H. Hawthorne, a

company director. On the 8th May, 1895, the

brigade faced a huge challenge when a large fire

occurred at the Deepfields site. It destroyed

the warehouse and most of the stock, and caused

around £5,000 worth of damage. The blaze was

brought under control by the Cannon fire

brigade, and fire brigades from Bilston, Dudley,

Tipton and Wolverhampton. In 1895, Cannon purchased

the business of Richard Hickman, a grindstone

manufacturer, and opened a grindstone

department, producing Cannon ‘Excelsior’,

‘Little Wonder’, ‘Standard’ and ‘Universal’

grindstones, as well as glass cutting stones. |

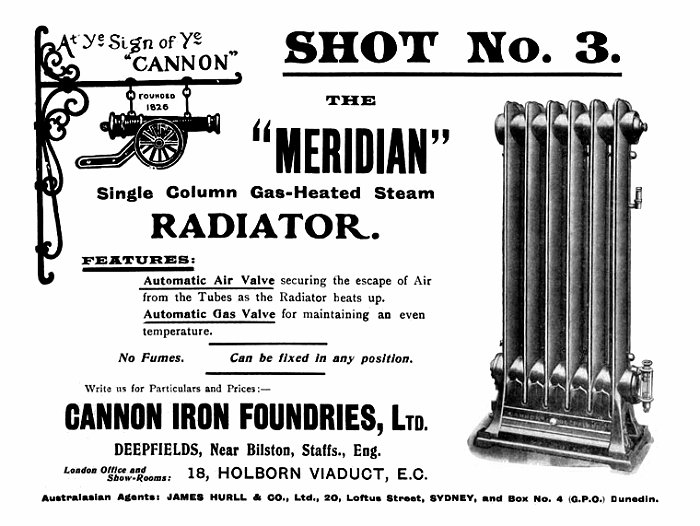

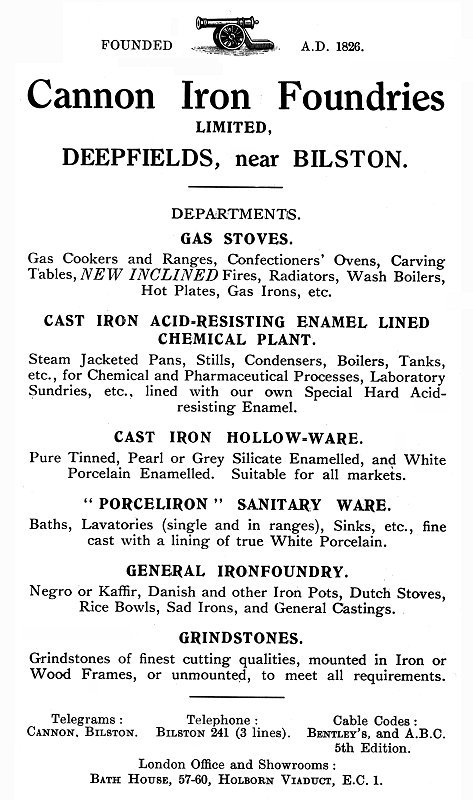

An advert from 1909.

|

In 1900, the firm became

‘Cannon Iron Foundries Limited’, to reflect the

wider range of its business, which included

Cannon sad irons, cast iron door hinges, axle

pulleys, and even dumb bells for keep fit

enthusiasts. Richard Clayton, who lived at

Coseley Hall, became Chairman and Managing

Director. By 1902 the firm had around 700

employees, including 40 clerks.

The ‘Porceliron’ trade mark

was also used for a wide range of enamelled

sanitary ware, including baths, toilets,

urinals, showers and foot baths, which all sold

extremely well. Products were also developed for

the chemical industry including autoclaves,

boilers, bowls, condensers, crystallisers,

digesters, evaporating pans, stills, and tanks.

The firm even produced ‘Cannon Cast Iron Quartz

Crushing Mortars, which were exported to the

goldfields in Australia and South Africa.

In 1905 the firm began to

manufacture gas meters in London, after

acquiring William Smith of London, a long

established gas meter manufacturer. The business

rapidly grew and large numbers were sold at home

and abroad. By 1914, the firm employed about

1,000 people and by 1926 the site covered 26

acres.

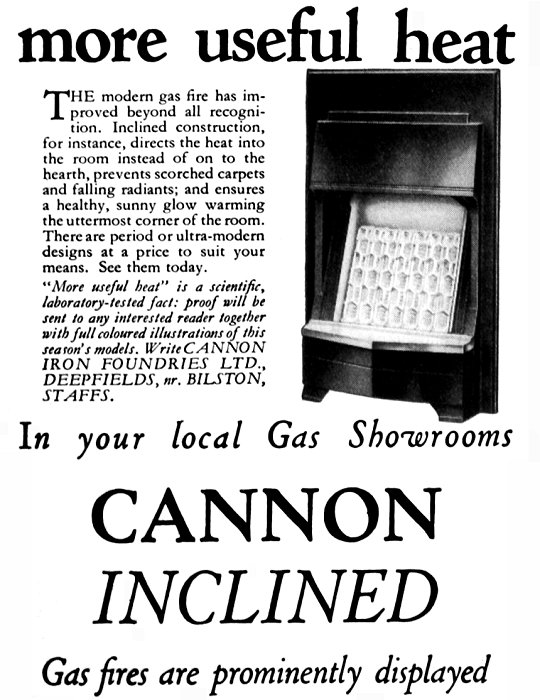

Cannon also became well

known for its gas fires, which were produced

from the early years of the 20th century and

became a

great success. The fires were finished with a

new patented enamelling process called ‘Vitro

Lustre’ that was extremely durable and

unaffected by the heat. Cannon also produced

gas-heated radiators. |

An advert from 1929.

An advert from 1934.

|

Cannon gas cookers became a

household name and were sold in vast quantities.

The first gas cooker left the factory in 1895.

At that time the gas stove department covered

300 square yards and grew so rapidly that by

1926 it covered 12 acres. This was made possible

because a new works was built to the east of the

railway line. The new factory, which opened in

1906, had the most up-to-date machinery and

extensive warehouses. Other products produced in

the new factory included bathroom geysers,

boiling rings, breakfast grillers, cooking

ranges, carving tables, hot closets for hotels

and schools etc., laundry irons, gas-heated

steam radiators, tailor’s heaters, washing

boilers, and water circulators.

|

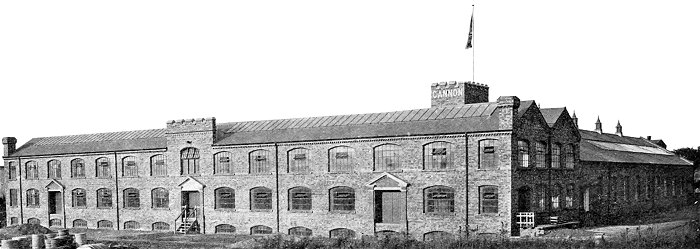

The new buildings

for the gas stove department, were erected in 1906 on six acres of land. From Cannon's

September 1915 Illustrated General

Catalogue. At the front is the warehouse,

with the fitting shops behind on the right. |

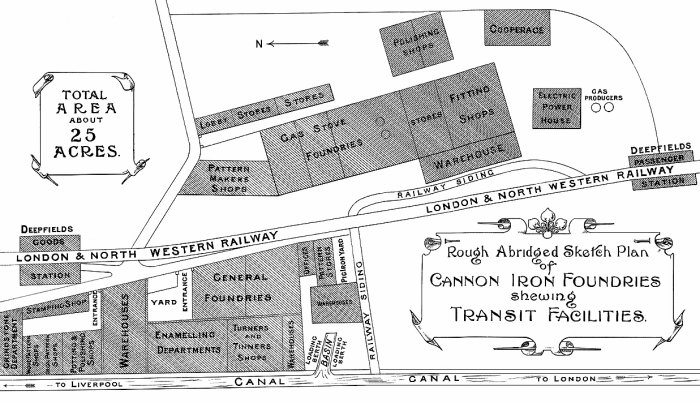

A plan of the old and

new works at Deepfields from a Cannon

catalogue of gas cookers, gas heating stoves

and gas meters etc., produced in about 1906. |

|

The opening of the new

factory coincided with the Cannon’s 80th

anniversary and so a celebration dinner was

held, at which a toast was drunk to the new

works.

One of the most popular of

the early gas cookers was the ‘Hercules’, which

efficiently used gas for baking, grilling and

roasting etc.

The company also introduced the

‘Chef’ cooker which was enamelled in dark green.

There were also ‘penny in the slot’ cookers and

the top of the range ‘Grosvenor’.

On Saturday 18th September,

1926, the company celebrated its centenary with

an excursion to Blackpool and a celebration

dinner.

Two trains carried 850 members of staff

to Blackpool, where they had an enjoyable day.

The celebration dinner was held in the Indian

Lounge at the Blackpool Winter Gardens.

|

|

|

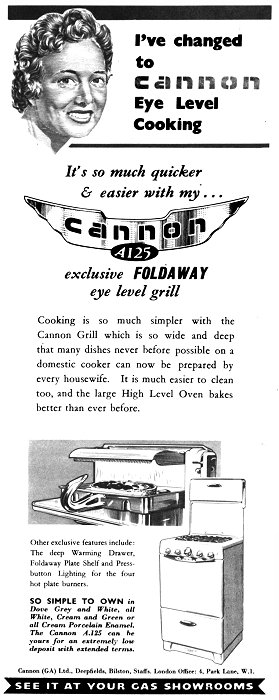

An advert from 1954. |

In the mid 1930s, the

company was incorporated and changed its name to

C.I.F. Investments Limited, on the 8th March,

1935. The name was then changed to Cannon Industries.

By the late 1930s, the

company’s products included the ‘Champion’ and

‘New Challenge’ gas cookers and the ‘Autimo’

inclined gas fire along with a range of portable

heaters and radiators. In 1952 the company changed

its name to Cannon (Holdings) Limited, and in

the following year, two subsidiary companies

were formed, Cannon (GA), gas appliance sales

and service, and Cannon (CP), chemical plant

sales and service. The subsidiaries were formed

when Cannon acquired the uneconomical Midland

Steel Company, which was closed. In 1959, Cannon

introduced ‘Power Maid’ multi-purpose kitchen

appliances, under a licence from the USA.

In the 1950s, Cannon became

one of the country’s leading manufacturers of

gas cookers and gas heaters. It was the first

company to introduce eye-level foldaway grills.

In 1964, GEC took over

Cannon Holdings Limited and in 1987, became part

of General Domestic Appliances, a joint venture

company owned by GEC and GE of America in 1987.

In 1993, Cannon's manufacturing facility and

offices moved from Coseley to Blythe Bridge,

Stoke-on-Trent.

The original foundry has

since been demolished and houses have been built

on the site. The later development on the other

side of the railway has been transformed into

Cannon Business Park, where a large number of

businesses are based. A few of the old

outbuildings still survive and have been sold to

various businesses. |

|

|

|

Return to the list

of

companies |

|