General Metal and Holloware

In his History of Bilston in 1897 G. T. Lawley provides some information on the origins of this company. He wrote:

He also says that "in addition to General Castings manufacture Tinned and Enamelled Cast Iron Hollow-ware for the foreign markets exclusively". Presumably this is intended to mean that they make castings for all markets but they make holloware only for the export market. Sheldon's were one of the companies that had themselves written up in the Staffordshire Illustrated Review in the 1890s. Here is a slightly curtailed version of the report and the photos that accompanied it. "Originally founded in the year 1853 by the late Mr. Thomas Sheldon, the concern was steadily developed by that gentleman with untiring energy and enterprise until his death in 1878, after which the business was continued under the able management of Mr. Joseph Millington, a son-in-law, who now takes the sole direction of affairs.

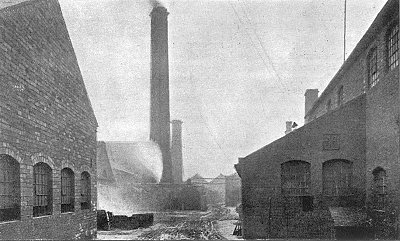

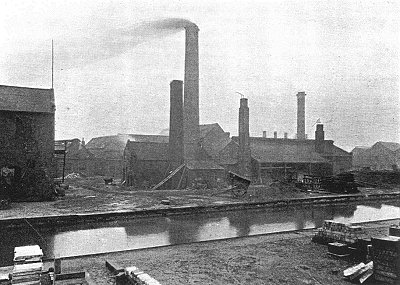

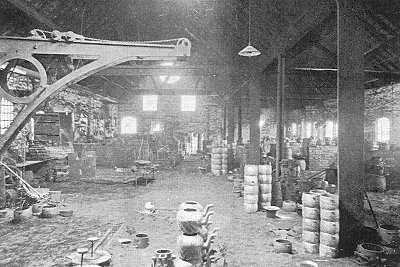

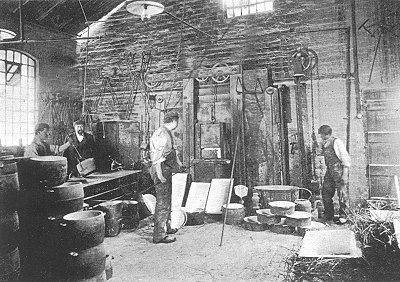

In the front portion of the premises are the offices, warehouse, and pattern room, flanked by a gateway entrance giving admission to the works. To the right is a two-storeyed building, of which the ground floor is occupied as warehouse for finished goods ready for immediate delivery, and the upper portion for reserve stocks. Beyond is the spacious yard, in which is erected the large cupola and foundry, the latter furnished with a powerful travelling crane and all the necessary plant for the production of light or heavy iron castings. The principal items of output in this department are cast-iron hollow-ware culinary utensils, and some interesting shapes peculiar to the firm's foreign trade, including long and short legged Negro pots, Danish pots, camp ovens, and a speciality in the fluted-leg Dutch stove with ring handles. In this department, too, are cast all sizes and shapes of sad irons, of which the " Star" pattern, with round and sharp point, is made on an American design, of which Messrs. Sheldon are sole manufacturers in this country.

On the other side of the yard is a building used as pattern stores and stock warehouse, and adjacent are the enamelling shops, furnished with two dry and two wet mills and the usual stoves; varnishing shop, fitted with tanks, etc; hollow-ware stores, and the turning mills, where the inside of the vessels are smoothed. In the tinning shop we had an opportunity of seeing this process performed, and here may be mentioned as an important feature of this department that none but the best pure English refined tin is used in coating the insides of the hollow-ware. A fine new engine of 30-horse power, recently erected by Tangyes Limited, provides driving power for another portion of the machinery, steam for both engines being generated in three large boilers. In a portion of the premises is stacked a large quantity of timber used in making the packing cases for export, which are constructed on the ground, of hard wood of substantial thickness. Returning from our tour of the works, we had the opportunity of inspecting the various classes of goods in the warehouse, of which the following particulars will undoubtedly prove of interest to our readers in the trade.

The special feature of Messrs. Sheldon's enamelled hollow-ware is embodied in the report of 28th of March, 1887, of Mr. E. W. T. Jones, F. I. C., the public analyst for Staffordshire, who states "I have made an exhaustive chemical examination of the enamel on this hollow-ware, and find it is free from any metallic, or other substance of the least objectionable character on sanitary grounds for the lining of culinary utensils . . . . . The enamel is also wonderfully acid proof. I have boiled strong mineral (hydrochloric) acid and acetic acid in saucepans and left in them several days without the surface of the enamel being affected." In their tinned cast-iron saucepans the firm have advantageously introduced their patent socket handles and seamless steel covers. The first, by a patented process, can be applied to all saucepans, stewpans, etc., with the utmost simplicity by unskilled hands, and as the improved handle can also be supplied loose economy in packing is ensured and all screws, cones, rivets, punches, or other loose appliances are quite unnecessary. A marked improvement also is the firm's seamless steel covers, which are made in one piece without seam or rivet, and with curled-in, or double-edged rim, the superiority of which over the old style, with a sharp edge, is perfectly obvious. These covers are also re-tinned after stamping, thereby adding greatly to their strength and durability. A body, numbering about 200 hands, is employed in the several departments to which allusion has been briefly made, and with the admirably-organised mechanical resources of the well-equipped works, it may be readily inferred that the annual output of the Spring Vale Foundry is on a scale exceeded by few other firms in the South Staffordshire hollow-ware trade. It was but natural to enquire the destination of this vast quantity of manufactures for such an infinite range of utility, a query promptly answered by the fact that goods bearing the "Star" brand of the firm are familiar both within and without the confines of civilisation, and quite as acceptable to the natives of "Darkest Africa" as to the inhabitants of the busy industrial centres of our own country, our colonies, and, in fact, in every quarter of the globe to which British enterprise has penetrated in the markets of the world." That ends the report from the 1890s. It may suggest that Sheldons were no longer selling their cast iron holloware exclusively into the overseas market. Indeed, Sheldon's goods can still be found in this country. Their irons, for example, sometimes turn up in antique shops.

Note: this company is Thomas Sheldon & Co. Ltd., founded in 1853 by Thomas Sheldon. A different company, E. Sheldon & Co was founded in 1826, presumably by E. Sheldon, and became Cannon Holloware Co Ltd. in 1884. The two companies had premises in the same district. Whether there was any connection between the companies or their founders is not known. |