|

|

About the Industry |

|

Enamels, japanwares and steel jewellery provided the glamorous side of

Wolverhampton's industry. But from the eighteenth century to modern

times Wolverhampton has produced millions of more prosaic items in

metal, for domestic, commercial and industrial use. Many metals

were used - iron, steel, copper, brass and so on. These might be

left with no finish at all or they might be finished, for decorative or

utilitarian purposes, in any number of ways, whether by coating the

surface or embossing, stamping or pressing patterns into the material.

Wolverhampton had easy access to coal and somewhat more remote access to iron. But Wolverhampton was not particularly accessible: it had no sea port and no major rivers by which to get in raw materials or to distribute finished products. So the first metal working industries in Wolverhampton had to produce small items which were easily transportable. It was only the coming of the canals and then of the railways that made larger items practicable.

The Wolverhampton Trade Directory of 1780 says: "The trade of this and the adjacent places is chiefly in the iron, steel, and brass manufactories, as locks, hinges, steel buckles, steel toys ...". (Toys, of course, are not children's playthings, but any small item, usually decorative). The list of inhabitants in this Directory bears out this picture of the town's trade, with makers of small metal items predominating, almost to the exclusion of other manufacturing trades.

The story of this sector of industry therefore starts with small items made of metal, such as steel jewellery and "toys". It goes on with splendid decorative techniques such as enamelling and japanning. In all of these areas Wolverhampton, and what was then the separate town of Bilston, found world renown. By the end of the 19th century metalworkers were turning out large numbers of domestic hollowware and similar goods and this continued long after the other trades had either vanished or been greatly reduced. Tools of all kinds, including edge tools, were also largely made here, flourishing well into the 20th century.

|

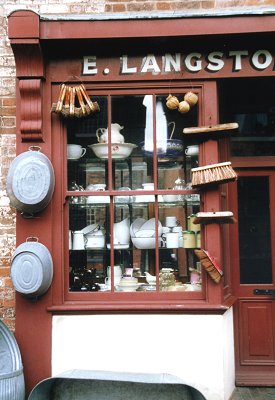

All the goods in this shop window at the Black Country Living Museum, including the brushes, galvanised tubs and baths in front of it, could have been made in Wolverhampton. The only exceptions would be the ceramic ware. |

In the first half of the nineteenth century these industries would still be on a very small scale - individual workmen operating from their own premises and rarely employing more than a few members of their own families. An enormous volume of production was achieved, not through large factories, but through a multiplicity of small workplaces. During the nineteenth century large firms appeared and, by the end of it, amalgamations and takeovers often occurred. But smaller firms always remained.

The trades could be greatly subdivided, so that individuals might engage in only one part of the production of larger objects. For example, there were individuals and companies which produced blank trays - which they sold to the japanning works; and other individuals and companies which made metal boxes - which they sold to the Bilston enamellers. These trades also produced spin off trades and industries: Manders started out as japanners but soon came to specialise in the making of the varnishes which other japanners bought from them - and from there expanded into many other finishes, from general varnishes, to enamels, to house paints and printing inks.

The crafts of these trades also proved to be highly transferable, so that many people engaged in them ended up in the vehicle manufacturing industries, applying high grade finishes to bikes, motor bikes and cars.

The large firms, and even some of the smaller one, produced a great range of products, often in a variety of materials. Wolverhampton firms do not appear to have been great innovators, whether in new types of goods or new methods of production. What they seem to have been good at was recognising new markets and responding to them. For example, the coming of the railways and a general increase in wealth, lead to a great boom in travel, whether for business or holiday purposes. This created a market for travelling trunks and all sorts of local companies, small and large, started making them. More and better houses meant more coal fires in houses - so Wolverhampton started producing coal scuttles and boxes in great numbers. And the coming of motor vehicles and aeroplanes lead many companies into new products, whether it was metal components for building vehicles or the paints and varnishes for finishing them. The general growth of industry itself lead to many firms making tools, including edge tools, in which Sheffield certainly did not have a monopoly (though we cannot find that Wolverhampton ever went in for making cutlery).

Many companies, especially the larger ones, did not confine themselves to a single product or even to a range of similar products. They tended to make whatever their equipment, premises and knowledge allowed. Some companies sometimes changed the nature of their business. For example, James Marston started off making domestic utensils, moved into cycles and motor vehicles and then sold off the non-vehicle side to Orme Evans. Indeed some say that "Sunbeam" was originally applied to the domestic utensils, not the bicycles.

What we exhibit in this part of the Metalware Hall are the smaller metalware items. The way we have divided up these items is somewhat arbitrary, as we feel it is bound to be; and the divisions between our arbitrary sections are somewhat vague, as we feel they are bound to be. So, for example, we have here fencing and railing; but steel structures which are buildings, or parts of them, are in the Engineering Hall (even though the fence and railing makers also made structures!). And, of course, Locks and Safes have their own Hall, which includes Lock and Door Furniture - letter boxes, finger plates and so on. Larger examples of metal bashing can be found not only in the Transport Hall but also in the Engineering Hall

We have no proper history of this section of the trade generally nor full histories of many of the companies. But in this Hall (and elsewhere in the Museum) you will find material which makes a start. What we exhibit here are just a few of the companies, chosen by the chance of material being to hand. We would greatly appreciate further information, including the recollections of anyone who worked with the firms mentioned or any others.

Such are the vagaries of economics and industrial upturns and downturns, that we have not been able to find out who might now be the inheritors or successors in title to many of the companies shown.