|

The Darlaston Iron

Bridge and Roofing Company Limited |

|

One of Darlaston’s once large

industries was the manufacture of structural iron and

steel work. Many of the country’s important buildings

and structures were built using locally made

fabrications. Darlaston based company’s including Rubery

Owen and E. C. & J. Keay Limited were known throughout

much of the world.

The industry started in the town in

the 1840s in the first large factory in the area; King's

Hill Works, that was owned and run by S & R Carter.

Sadly the business ended in 1866 because the bank used

by the firm, the Birmingham Banking Company, suffered

serious liquidity problems and ceased to trade, leaving

Carters with many unpaid bills and angry creditors. As a

result the factory and contents were sold at auction in

June 1867 at the Old Castle Hotel in Pinfold Street.

The Darlaston Iron Bridge and

Roofing Company Limited was formed on 29th July 1867.

The Directors were Richard Mills, Samuel Rubery, and

James Slater. John Tunner Rubery became Company

Secretary, and Simeon Carter was Works Manager.

It is likely that the new company

acquired at least part, if not the whole of S & R

Carter’s Kings Hill Works to enable work to immediately

go ahead on several important orders including the

wrought ironwork for the roof of Liverpool Lime Street

Station. In 1867 to 1868 the station was lengthened and

widened. The northern-most bay of the roof, designed by

the London & North Western Railway’s Chief Engineer,

William Baker, was built at that time. Seven years later

the southern bay, also designed by William Baker was

added.

The roofs are 645ft long and cover

most of the platform area. The north roof was the

largest arched, single span wrought iron roof ever built

at the time. It took 2,500 tons of iron to build the

structure. The spans of the roof vary between 185ft and

215ft, with an average of 212ft. It appears that the

Darlaston Iron Bridge and Roofing Company were acting as

sub-contractors to G. Thompson & Company, Railway

Contractors of Liverpool, who were awarded the original

contract. The cylindrical cast iron columns were

manufactured by George Forrester & Company, Vauxhall

Foundry, Liverpool.

The roof was erected by the

Darlaston Iron Bridge and Roofing Company under the

watchful eye of the company’s Forman of Works, Mr. James

Kean. Work was completed in 1871 at a cost of £44,347.

|

Lime Street Station. Courtesy of Peter Carter.

|

The company may also have had a

site at Fallings Heath. In J. G. Harrod & Company’s

Postal and Commercial Directory of 1870 the company is

listed as: Darlaston Iron Bridge and Roofing Company,

Limited, Fallings Heath.

In 1871 Andrew Shirlaw, a Scottish

mechanical engineer became Managing Director of the

Darlaston Iron Bridge and Roofing Company, and by August

1872 the nominal capital had been increased to £20,000.

The shareholders were: Alexander Brogden M.P. for

Ulverston Lancashire; Simeon Carter, Works Manager;

Edward Eastwood, Wagon Builder at Chesterfield; Enoch

Horton, Nut & Bolt Manufacturer at Darlaston; Anna Wood, of St.

John’s Wood, London; Richard Mills; Samuel Rubery; John

Tunner Rubery; Samuel Rubery Junior; James Slater; and

Andrew Shirlaw.

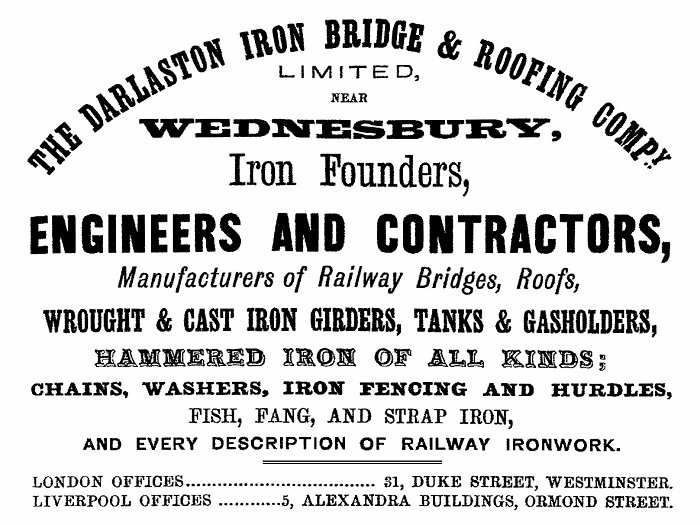

Around 1870 the company moved to a

new factory in Station Street, Darlaston, on a site that

is roughly opposite to where Salisbury Primary School is

today. It was an ideal site lying next to the Darlaston

Branch of the London & North Western Railway, giving

easy access to much of the country. The branch line opened in

1863. This was one of the first factories in the area,

which had previously been extensively mined for coal by Batchcroft Colliery. Other factories soon appeared

including Enoch Horton’s New Alma Works which was built

next door.

|

An advert from 1872. Courtesy of Peter Carter.

|

In the 1870s the London & North

Western Railway quadrupled the West Coast Main Line

between Stafford and Crewe to accommodate more rail

traffic. Plans for the scheme were drawn-up in 1871 and

the contract for new bridges was given to William Moss &

Son, contractors and builders, based in Wolverhampton

Road, Stafford. In October 1872 William Moss asked for

tenders for the ironwork for the bridges, which amounted

to around 1,200 tons of wrought iron in main girders and

cross girders, bent plates etc. all fixed and painted.

The contract for the ironwork was

given to the Darlaston Iron Bridge and Roofing Company

in November 1872. The company had quoted the following

prices per ton: wrought iron bridges - £19, cast iron

bridges - £9.10s, and bolts - £24. The total cost of the

materials quoted came to £22,589. It was later

discovered that an extra bridge which had not been

included in the original plans was required. The

Darlaston company supplied the ironwork for the bridge

at a cost of £319.

The project was completed in 1876,

but William Moss withheld part of the payment to the

company because some cappings on the bridges had not

been supplied. This resulted in a court case in the High

Court of Justice, in London in 1877. The Darlaston

company claimed £2,843 for the capping and the extra

bridge, and a full payment totalling £25,632.

In June 1872 the company was

awarded a contract by the Liverpool Corporation Health

Committee for the ironwork for a wrought iron arched

bridge to carry Sandhills Lane over the Leeds and

Liverpool Canal. The Sandhills Bridge is still in use

today.

In 1873 Simeon Carter, Works

Manager at the Darlaston Iron Bridge and Roofing Company

left to start his own business. In 1870 he had purchased

some land at James Bridge from James Slater and Richard

Mills on which he opened a new factory under the name of

Carter, Ford and Company Limited.

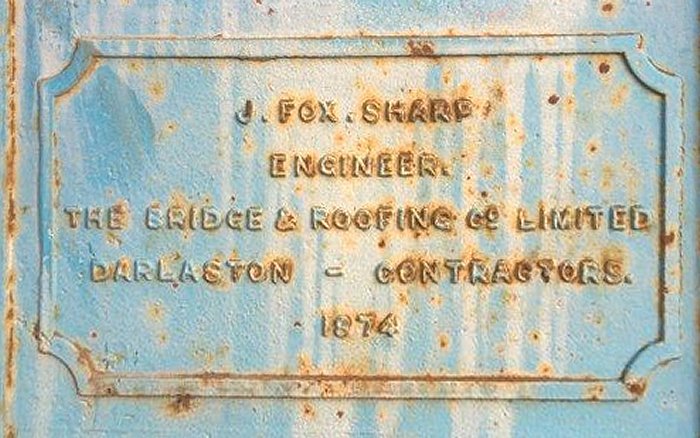

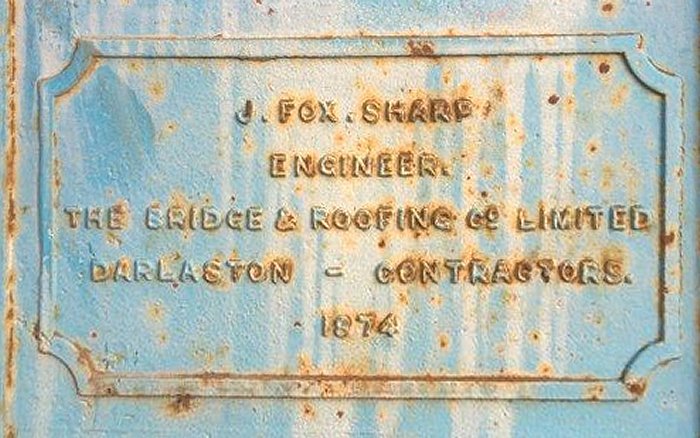

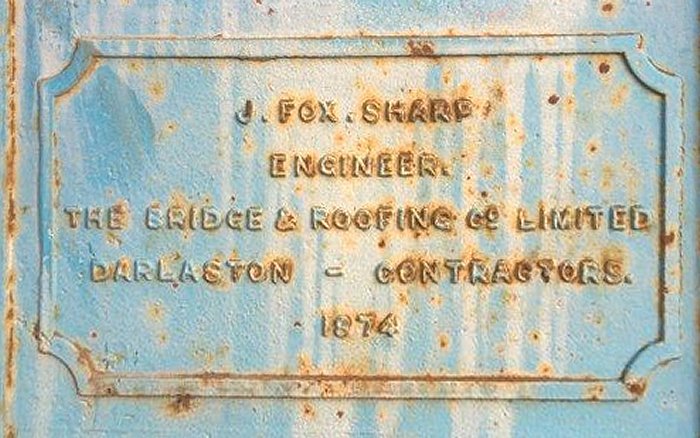

The Bridge and Roofing Company

Limited

In September 1873 the Darlaston

Iron Bridge and Roofing Company became The Bridge and Roofing

Company Limited. One of the company’s projects

was the construction of Sculcoates Swing Bridge over the

river Hull, in Chapman Road, Hull. It was constructed in

1874 and is now Grade II listed. The bridge officially

opened in January, 1875.

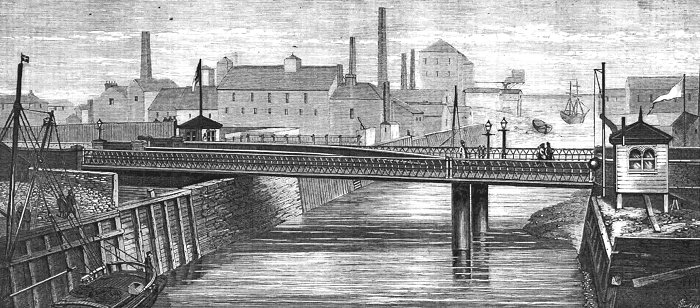

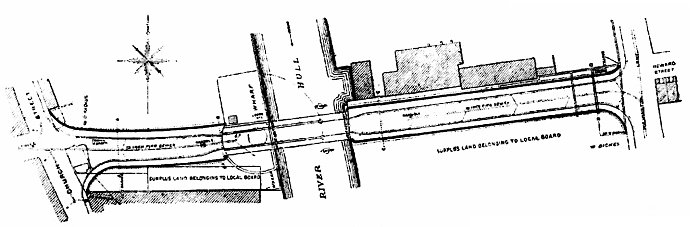

|

From Sculcoates Bridge.

From Sculcoates Bridge.

| From The Engineer,

2nd April, 1875.

Sculcoates Bridge,

Kingston-upon-Hull

We give this week the

first of two working drawings of the new

bridge at Kingston-upon-Hull, opened to

the public by the Mayor and Corporation

on the 9th January. The bridge is over

the River Hull, and is constructed in

two spans of 56ft. and 27ft., the wider

span being movable for the purpose of

navigation. The appearance of the bridge

is light, though at the same time its

structure is substantial.

The swinging portion of

the bridge is formed by two longitudinal

plate girders, 113ft. in length,

supporting a carriageway between them

and footways on cantilevers on each

side, and at the tail end of each girder

a cast iron counterbalance box of

ornamental design is constructed in

three compartments, the arms of Hull,

encircled with a festoon and riband,

being cast in relief on the two end

panels of the side elevation. The

introduction of a counterbalance box in

this manner gives a character to the

design, and greatly adds to the

symmetrical appearance of the structure,

and is, we believe, the first

application of this feature to a bridge

of this description.

The turning

machinery is in duplicate, and is fixed

in and under the counterbalance box,

where it gears into a rack fixed round

the circular retaining wall of the

bridge pit, and is worked by hand power

from the footpaths. The moving load, 240

tons can be opened or closed by four men

in two minutes. The motion of the bridge

whilst it is being turned is perfectly

smooth and without any perceptible

vibration. The pier in the centre of the

river consists of two cylinders 5ft.

6in. in diameter at the bottom, and 4ft.

3in, at the top, of cast iron, varying

from 1⅛in. to 1¼in. in thickness.

The method adopted

for the sinking of the cylinders was by

excavating from the interior and by

weighting. They were sunk by this means

to a depth of 22ft. below the level of

low water of ordinary spring tides, or

to about 18ft. below the bed of the

river, when a hard dry bed of the

boulder clay was reached. After being

sunk to within a few inches of the

required level, they were filled with

cement concrete, and each subsequently

weighted with a load of 96 tons, which

was kept on until the cylinders remained

perfectly stationary for 24 hours, the

north cylinder being forced into the

clay 1⅛in. during the process, and the

south cylinder 1 and 17/32in.; and it is

noteworthy that the actual depth to

which they were sunk was within 1 and

1/14in. of each other, so that the

uppermost castings, which it is usual to

leave off for adjusting any differences

in this respect, had only to be varied

to that small extent.

The strength of the bridge was tested

with most satisfactory results with a

weight of 50 tons, when the deflection

was only ¼in., and it resumed its

original level on the weight being

removed. The whole has been erected from

the design and under the immediate

superintendence of the engineer and

surveyor to the local board, Mr. J. Fox

Sharp, C.E.; the contractors for the

ironwork being the Bridge and Roofing

Company, Darlaston, and for the masonry,

Messrs. Simpson and Malone of Hull. |

|

|

In October 1874 The Bridge and

Roofing Company Limited won a contract to build a large

road bridge over the Metropolitan Railway at Farringdon

Road. The company quoted £18,250 for the work. Other

contracts included the Egremont Ferry Pier and the

floating approach to the Princes Landing Stage, including

the six sets of pontoons that supported the staging.

On 15th November 1876 the London &

North Western Railway put out for tenders for the

construction of a second shed at Liverpool Lime Street

Station. The contract was awarded to The Bridge and

Roofing Company Limited at a price of £35,840. The roof

which had spans varying from 170ft to 195ft was erected

by E.W. Ives, Civil Engineer of London. The project was

completed in the middle of 1879.

|

Lime Street Station.

In June 1883 The Bridge and Roofing

Company were awarded a contract for the building of

towpath bridges over the river Soar in Leicester for

£849. Other projects included the roof of the new

Midland Railway station built alongside Birmingham New

Street Station, covering 16,000 square yards. One of the

sub contractors for ironwork was Horton and Son,

Darlaston.

In the mid 1880s a

growing preference for the use of steel rather than iron

led to a reduction in orders and the closure of the

company in about 1886. On 25th and 27th of May 1887 much

of the

company’s machinery etc was sold in a two day sale, held

at the factory. The factory was acquired by Horton and

Sons in 1891, and the Bridge and Roofing Company

Limited was officially dissolved on 21st June, 1892.

The

company's projects included:

Liverpool Lime Street

Station North Shed 1867-71

Snow Hill Station Roof, Birmingham, around 1871

Radcliffe-on-Trent Viaduct 1872

Sandhills Bridge, Liverpool over the Leeds and Liverpool

Canal 1872-4

All the Bridges on the widening of the LNWR line from

Stafford to Crewe 1872-5

Bridge over Metropolitan Railway at junction of

Clerkenwell Road and Farringdon Road, London 1874

Egremont Ferry Pier 1874

Sculcoates Swing Bridge, Hull 1874

Floating Approach to Princes Landing Stage, Liverpool

1875

Birkenhead Station Roof 1878

Liverpool Lime Street Station South Shed 1876-1879

Birmingham New Street Station, Midland Railway terminal

1884

|

| I have to thank Peter Carter, who supplied much of the

information. He has extensively researched his family and

their various business ventures. |

|

Return to

the

previous page |

|