| Rubery

Owen (Warrington) Limited |

|

In 1939 Rubery Owen acquired

Electro-Hydraulics based in Warrington, makers of

undercarriages and hydraulic equipment for aircraft. In

March 1943 its engineering work was transferred to a new

company, Rubery Owen (Warrington) Limited, and its

machine shop was built beside the Electro-Hydraulics factory

in Liverpool Road, Sankey, Warrington. |

|

The company had a three-storey office

block, supported by steelwork produced by Rubery Owen’s

Structural Department. It rested on around 60 piles driven

30 feet into the ground.

The main workshop covered around 60,000

square feet, and was divided into three areas, road making

and material handling equipment, lathes, and front and rear

axle assemblies for motor vehicles, and for the company’s

Conveyancer fork lift trucks, built in the factory next

door.

There was also a toolroom, an inspection department,

stores, a maintenance department, light plate shop, joiners’

shop, a compressor house, and the constructional shop where

main frames, and thousands of fabricated parts were produced

each week. The shop was dominated by a large press brake. In

the yard stood the boiler shop, canteens, and kitchens. |

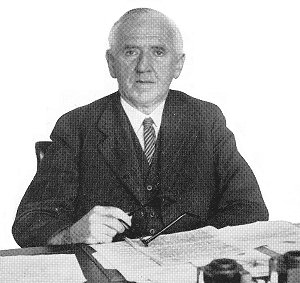

Mr. J. Pratt, Managing Director. From

the Christmas 1947 edition of the staff magazine "Yuletide". |

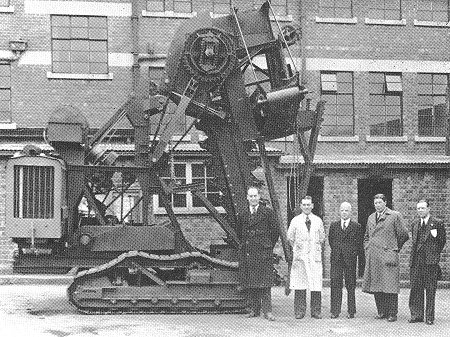

The first Barber-Greene Ditcher

produced by the company. From the summer 1951 edition of the

staff magazine "Goodwill". |

During the Second World War the factory

produced around 600,000 anti-aircraft and field gun shells,

mortar bombs, 11,000 Bailey bridge panels, 3,700 tail wheel

assemblies for heavy bombers, 2,500 castings for Bofors

guns, 2,300 axle and brake assemblies, and 600 paravanes.

The factory employed around 550 people,

under the leadership of Mr. J. Pratt, Managing Director, and

Mr. A. W. Hill, General Manager and Director. |

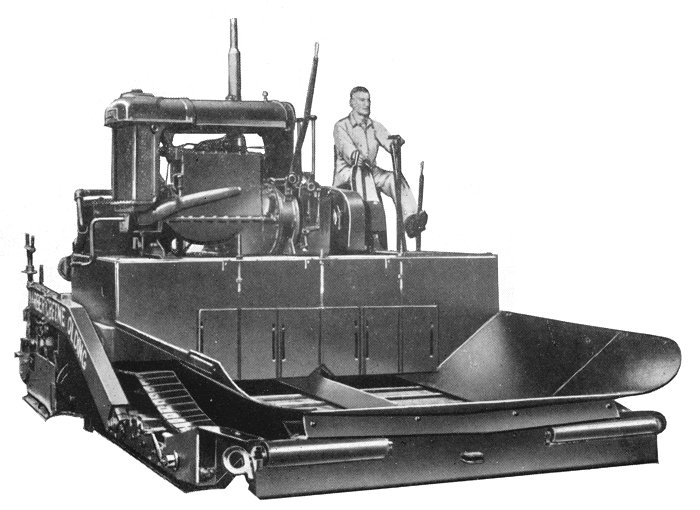

| One of the company’s products was a road-making machine

known as the Barber-Greene bituminous finisher which could

lay vast amounts of tarmac in a very short time.

They were originally used in this country for laying

aircraft runways during the Second World War. There were

only twenty one of them in the country, and because of the

high demand in North America, the Illinois-based

Barber-Greene company decided to concentrate on their home

market. |

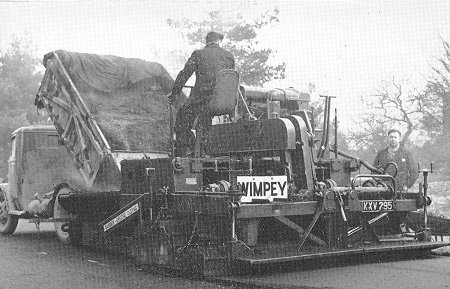

A Barber-Green 879A Road Finisher.

From the summer 1951 edition of the staff magazine

"Goodwill". |

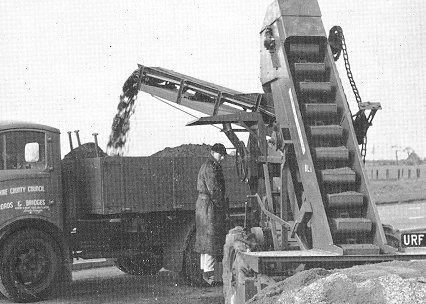

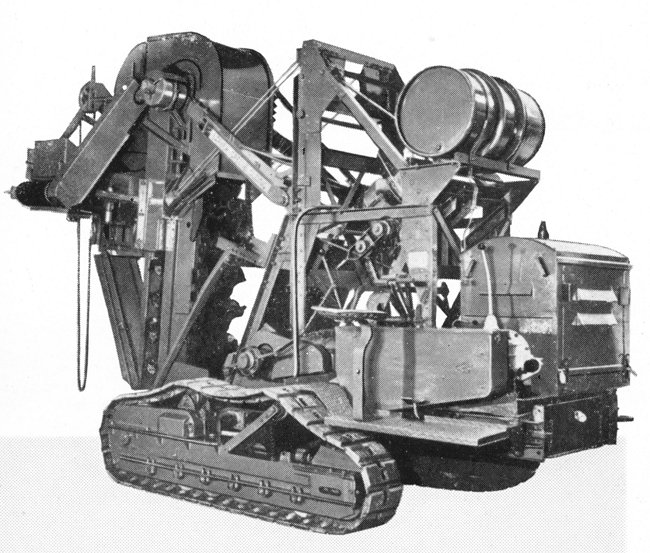

A Barber-Greene 44C Ditcher. From the

summer 1951 edition of the staff magazine "Goodwill". |

In 1946 Barber-Greene Olding & Company Limited, of

Hatfield, Hertfordshire, placed an order with Rubery Owen

which involved drastic modifications to the American design.

Soon a new version of the machine came into being, which was

manufactured in its entirety by Rubery Owen (Warrington)

Limited.

Other road-making machines including the Barber-Greene

Ditcher, and the Barber-Green Bucket Loader were produced by

the company. |

| Another of the company’s successful products was the

'Eaton' two-speed axle for heavy lorries, produced for the

Eaton Manufacturing Company of Cleveland, USA., and also

trailer axles produced for Trailmobile (Canada) Limited.

The factory also produced Harrison seven inch centre

lathes, most of which were exported to North America and

Canada.

Production ended in the late 1980s as a result of the

industrial recession. The company was finally dissolved

in 1993 when Rubery Owen moved away from manufacturing. |

A Barber-Greene Model 522 Bucket

Loader. From the summer 1951 edition of the staff magazine

"Goodwill". |

|

A Barber-Greene Olding bituminous

finisher for road maintenance. |

A Barber-Greene Olding Model 44C

vertical boom ditcher. It could cut trenches from 18 to

24 inches wide, and up to 8 ft. 3 inches deep. It was

powered by a Henry Meadows diesel engine. |

|

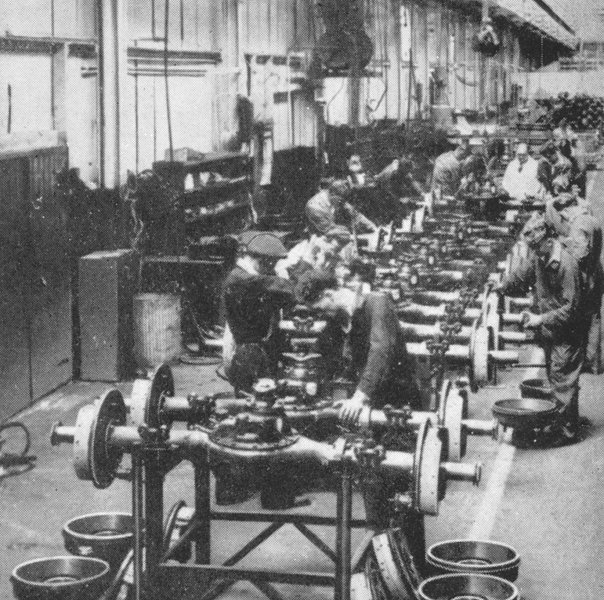

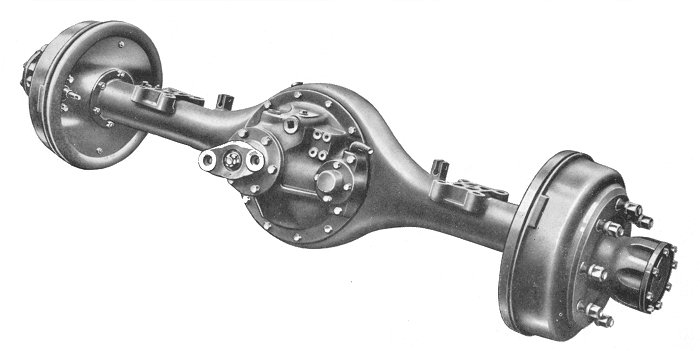

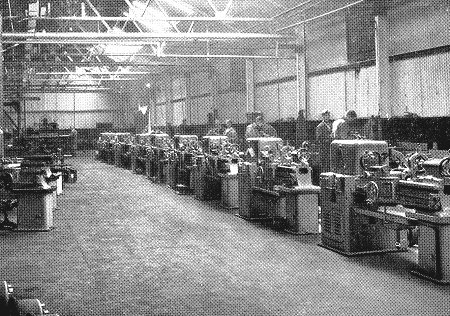

Production on a large scale of

'Eaton' 2 speed rear axles. |

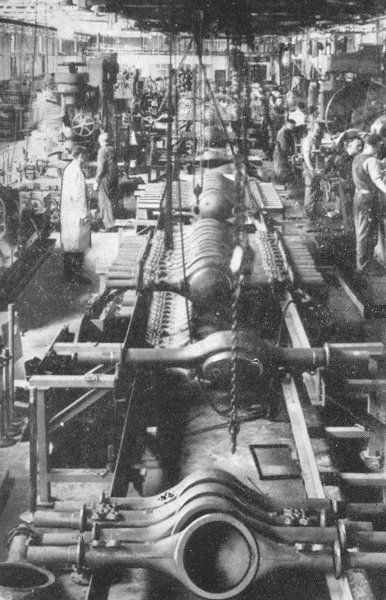

| Another view of the 'Eaton' 2

speed rear axle production line. |

|

|

An 'Eaton' 2 speed rear axle. |

|

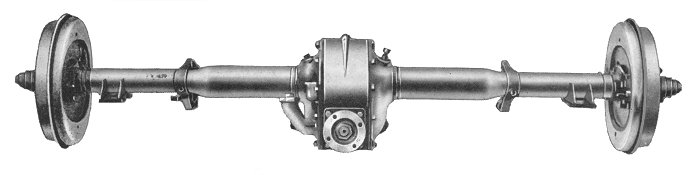

Another product, a rear axle for

taxis. |

|

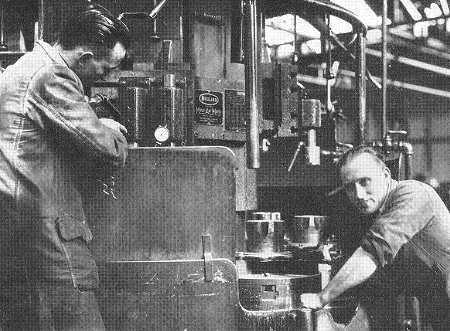

Jimmie Bennett, and Jimmie Norton

machining wheel hubs for Eaton axles.

From the Christmas 1947 edition of the

staff magazine "Yuletide". |

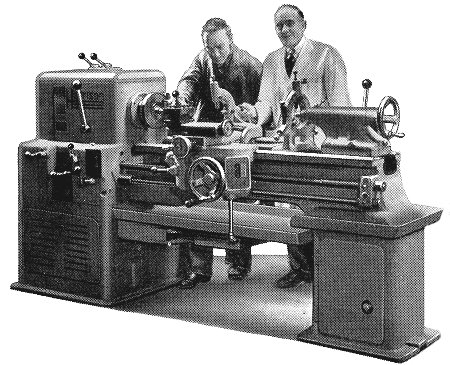

| A Harrison lathe being finally

inspected. From the Christmas

1947 edition of the staff magazine "Yuletide". |

|

|

A line of completed Harrison

Lathes awaiting despatch.

From the Christmas 1947 edition of the staff magazine

"Yuletide". |

|

Return to

the

previous page |

|