|

The Mechanical Filtration and Softening of

Water

|

The mechanical filter. |

|

The most

frequently adopted method of

filtering water is that of slow sand

filtration, which requires a large

area of land and a small filtering

bed, the rate of filtration varying

between one and four million gallons

per acre per day.

In places where

the price of land renders this

system impracticable, and where the

cost of the filters is a matter of

consideration, mechanical filters

can be substituted, as they not only

take up very considerably less

space, but also compare very

favourably with the slow sand

filters as regards working costs. It

should be pointed out that the term

"mechanical" here applies to the

means adopted for cleansing the

filtering material.

There are two

principal methods of cleansing in

use. In one, the water is caused to

flow through the filter bed in the

opposite direction to that in which

filtration usually occurs, air being

also injected underneath the bed. In

the other the reverse flush of water

is used simultaneously with a

mechanical agitator.

Some makers

introduce the necessary air by means

of a steam injector. In the

apparatus we are about to describe,

which is made by Rubery, Owen and

Co., Darlaston, the steam jet is

done away with and the reverse flush

itself is utilised to inject the

air. In addition, a hand-operated

agitator is provided, so that the

filtering material is thoroughly

broken up and a uniform contact with

the air results. |

|

The header tank

A contains a supply of clean

water which flows through pipe B

into the cone D from where

the water carries a current of air

from openings T1

and T2 into space

F, beneath the filters H.

The filters

have been specially designed for the

bacterial purification of water for

town supplies, and are employed in

conjunction with coagulants, by

means of which a film is formed on

the bed artificially. The coagulant

is introduced into the pipe which

supplies the filter with water.

The makers

claim that, owing to the filter

being covered, the growth of algae

is prevented, and the formation of

the desired film is under control,

the time required for the growing

process being only a few minutes.

The water and

air pass upwards through the

filtering material, and the air

finally escapes by way of an air

pipe not shown. |

|

A sectional elevation of the

mechanical filter. |

|

The unfiltered

water enters at P, and the

filtered water passes through the

filtering medium H and

perforated filtering plate G,

fitted with specially constructed

screening chambers and gauze

screens. The filtered water flows

into the header tank via pipe U

and flows out of the header tank

through pipe L. Wheel S

allows the filter to be agitated. |

| |

|

|

|

|

|

|

|

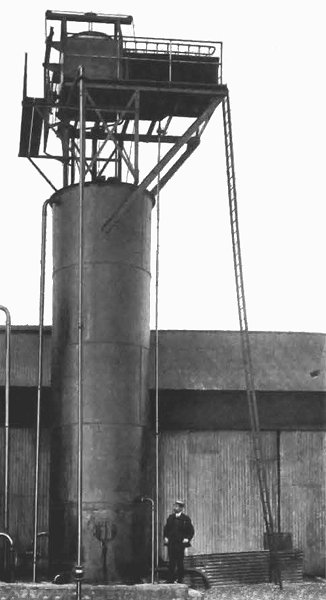

The Andrews

Water Softener. |

Andrew's patented

water-softening plant is another device made

by the same firm. The plant illustrated in

the photograph has been erected at Messrs.

Rubery and Owen 's works at Darlaston where

it is effectually reducing hard water of

from 54 deg. to 6 deg. of hardness. It can

soften 5,000 gallons of water per hour.

The hard water enters

header tank A and flows out through

valve B into cone J where it

is mixed with milk of lime from the chemical

tank H via pipe R, and air.

The passage of the water and chemicals

together down pipe S and cylinder

L, together with the impact against the

baffle-plate K and the addition of

air ensures an intimate mixing of the whole.

The treated water next passes through the

openings in the bottom of the cylinder L

and the stand pipe T to the sand

filter U where it is deprived of its

precipitate, consisting of a powder which

would otherwise find its way into the

boiler. When header tank A has

emptied, the fall of the float C

brings the tripping gear into action and the

positions of the passages in the two-way

valve B are reversed. The header tank

again fills, and when full, valve B

operates and the whole process starts again.

The tripping gear. |