|

The Weldless Steel Tube Company

Limited, Waddens Brook Lane, Wednesfield was founded as

a private company in 1872 by three members of the Lloyd

family; William Ellis Lloyd, William Henry Lloyd and

Francis Henry Lloyd. The factory was in Ladywood,

Birmingham, alongside Icknield Port Road and Freeth

Street. The original process began by producing a steel

billet on one of the firm’s two Swedish barrel type

rolling mills. The seamless tubes were produced by

boring a single hole down the middle of a steel billet

and expanding it. Initially tubes were produced from 1¾

inches to 5½ inches in diameter. The firm was originally

called the Wellman Steel Tube Company and made tubes for

bicycle frames, boilers, hydraulic presses, and

shafting.

By 1894 there was a great demand

for bicycles, and much of the available tubing for cycle

frames was rapidly being acquired by American companies.

This led to shortages and so the company acquired a site

in Rotton Park Street, opposite the existing works and

alongside the canal, for the building of a second

factory. Production began there in about 1897. |

|

An advert from 1899. |

|

In 1899, on the death of William

Ellis Lloyd, and the retirement of William Henry Lloyd,

Weldless became a public limited company, with Francis

Henry Lloyd as Chairman. The company was valued at

£100,000 and at the time produced around 50,000 feet of

tube per month, up to 6 inches in diameter.

The Directors were Francis Henry

Lloyd J.P. of Stowe Hill, Lichfield, Chairman; George

Herbert Lloyd of Sutton Coldfield; John Wilson of 49

Lime Street, London; William Uprichard Jackson and

Francis Zachary Lloyd.

In 1901 the firm leased Reliance

Works in Wednesfield and purchased the factory in 1907,

followed in 1911 by the acquisition a steel mill at Hope

Works, nearby in Wednesfield. The mills at Reliance

Works were improved, so that by 1909 it was possible to

roll tubes with an outside diameter of 3½ inches. Hope

Works produced 2½ to 3 cwt. Ingots in all types of

carbon steel. During the First World War there was a

huge demand for tubes as part of the war effort. |

|

An advert from 1926. |

|

Francis Henry Lloyd had a terrible

shock in June 1915 when his youngest son, Major John

Francis Selby Lloyd of the North Staffordshire Regiment,

was killed in action. Francis never got over the shock.

Francis Henry Lloyd (born in 1844)

also founded Europe's largest steel foundry, F. H. Lloyd

& Company Limited, in Wednesbury. He lived at Wood

Green, Wednesbury until 1890 when he and his family

moved to Stowe Hill Mansion at Lichfield. Francis sadly

died in January 1916 after being hit by a train whilst

taking a short cut to the railway station at Darlaston,

before catching his train home. He was succeeded as

Chairman by Francis Zachary Lloyd, who in 1920 decided

to close the Birmingham factory in order to concentrate

production at Wednesfield.

Francis Zachary Lloyd (born in 1869

in Wednesbury) died at his home, Areley Hall near

Stourport, in 1920. He was awarded a C.B.E. for his work

on the organisation of supplies during the First World

War, and became a member of the Iron and Steel Institute

in 1920. After Francis Zachary Lloyd’s death, W. V.

Jackson became Chairman and R. E. Moynihan became

General Manager. The other Directors were Daniel Charles

Lloyd (son of Francis Henry Lloyd) and Mr. J. Wilson. |

|

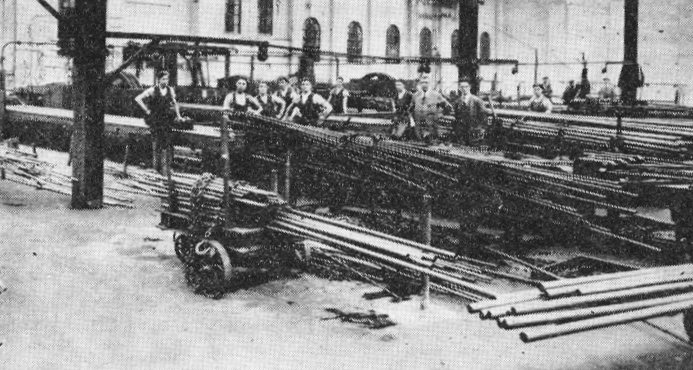

Cold drawing in Hope Works. |

|

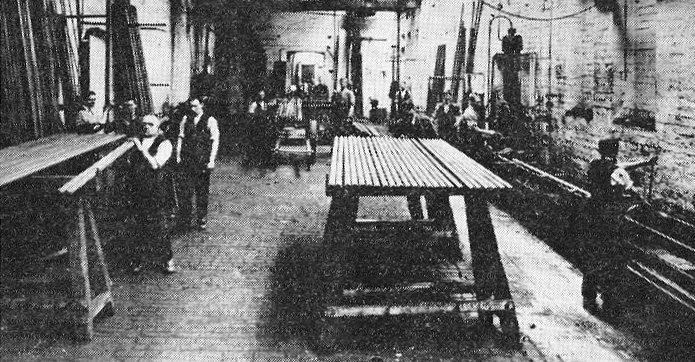

Hydraulic drawing in

Reliance Works. |

|

Tube cutting

equipment. |

|

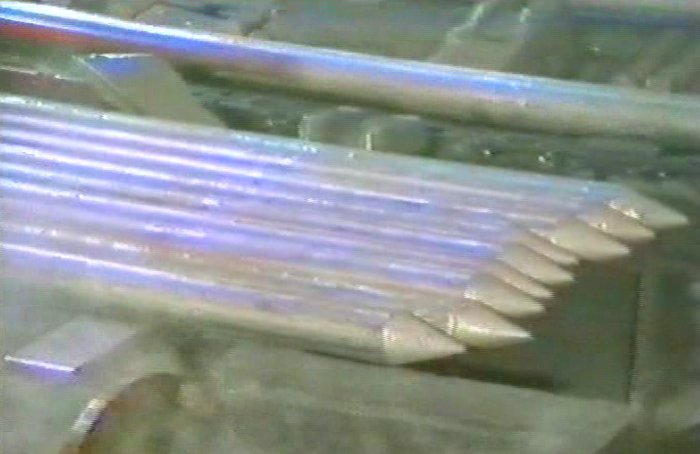

Mandrel Bars. |

|

A corner of the rolling mill. |

|

Operating part of the complex

computer control system. |

|

One of the computer displays. |

|

The firm began to suffer from the

effects of the global depression in the early 1920s

which resulted in the closure of the factory from around

1922 until 1924. It became part of Tube Investments

Limited in 1929, but closed again in the early 1930s

because of the great depression. The factory opened

again in 1934 and in the Second World War concentrated

on the production of aircraft gas cylinders and barrage

balloons.

By the 1950s, orders were in

plentiful supply and in the late 1950s the company

claimed to have produced the world's longest rolled

stainless tube, which was over 55 feet long, with an

outside diameter of 6 inches. New machinery installed in

1954 included two Pilger mills of the latest design,

with ancillary plant, including gas producers.

A big development took place in

1969 when a £10 million continuous tube mill was installed,

consisting of a three roll piercer, a mandrel mill to

elongate the pierced billet, and a stretch reducing mill

to produce the final size of tube required. The new

plant could produce more than 100,000 tons of seamless

tubes each year in the continuous mill. There was also a

specialised finishing plant at Corby. Products included

boiler tubes, and tubes for process plant, power

generation, pipelines, vehicles, construction equipment,

oil wells, mineral exploration, and sporting goods such

as golf clubs and bicycles. |

|

An aerial view of the factory. |

|

The outside storage area. |

|

Tubes were produced in three

stages. Initially a solid billet was pierced on the

unique three roll rotary piercer, followed by

elongation over a mandrel bar to achieve a

controlled wall thickness, before rolling to a

finished diameter on a stretch reducing mill. The

continuous process was accurately monitored and

controlled by a sophisticated computer system, with

quality control forming an integral part of

production. Many of the firm’s products went abroad,

to countries including Burma, Cuba, Jamaica, New

Zealand and Norway.

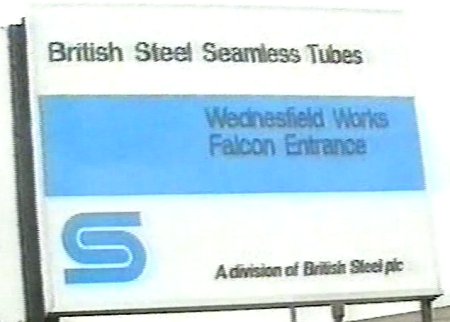

In the 1970s the firm became T

I Weldless Limited, by which time around 1,500

people worked in the factory. On the 22nd December,

1983, the company became Seamless Tubes Limited. By

the early 1990s the firm was finding it difficult to

compete with cheaper foreign competition and began

to make a loss, which by the mid 1990s had increased

to around £2 million annually. By this time it was

part of British Steel Seamless Tubes and mainly

produced oil and gas pipes, and axles for lorries. |

|

Because of the annual loss, British

Steel decided to close the factory in 1995 and

commissioned Connell Brothers Limited, of Salford,

Manchester to demolish the buildings and make the 37

acre site safe. The closure resulted in the loss of 520

jobs.

The site then became part of Wednesfield Steelpark,

which was opened by the deputy Prime Minister, John

Prescott in 1999. |

|

Part of the factory. |

|

A final view of the factory. |

|

Return to

the

previous page |

|