|

Laura Eddowes is a sales estimator at the

long-established and important Wolverhampton firm of Steelway,

and she has contacted me to tell me about a remarkable first,

both for the company and the city.

Laura writes that "regular users of the

Bilston Road will be familiar with the Steelway factory, but

what they may not be aware of is the company's contribution to

road safety. Wolverhampton led the way in July 1934 when the

UK's first pedestrian safety barriers were installed at the busy

junction of Princes Square. Steelway manufactured these after a

long and careful experiment and with the co-operation and

assistance of Mr. Edwin Tilley, chief constable, and Mr. H. B.

Robinson, the borough engineer and surveyor. It was after an

accident involving a boy at Princes Square that a means of

protection was necessary. The barriers stopped pedestrians

walking off a blind corner into the path of motorists. Some

residents were unhappy at the change but where Wolverhampton

led, London followed. On March 19th, 1935, Mr. Hore-Belisha,

then Minister of Transport, inaugurated London's first

pedestrian safety barriers at Britannia Crossing, Camden. Of

course, they were supplied by Steelway. A full copy of the

company's archives including a photo showing the 1937 coronation

barriers being installed will be available later this year from

Wolverhampton Archives." |

|

Princes Square, Wolverhampton,

in about 1934. This

picture is important to Steelway as it shows the UK's

first pedestrian safety barriers which the company

supplied free of charge to Wolverhampton Council as part

of an experiment.

Steelway also has footage

showing Mr. Hore-Belisha inaugurating the country's

second barriers at Britannia Crossing, London, on March

19th, 1935. |

| Steelway's achievement was a resounding one,

especially for a relatively new company. The business

had only been founded in 1928 at the Queensgate Works

site in Wolverhampton by C. W. Goodyear. Three years

later it merged with F. Hammond & Co., a noted

manufacturer of handrail standards. |

|

Another view of those safety

barriers on the dangerous corner opposite the Royal

London Building. |

|

Barriers

Mr. Hammond joined the board of

directors, which also included F. H. Clark as chairman,

J. E. Bettles as a director, and Miss E. K. Holbrook,

secretary.

In addition Steelway was the sole

selling agent of drop forged handrail standards

manufactured by J. Brockhouse & Co. of West Bromwich and

in turn Mr. J. V. H. Brockhouse was the selling agent in

London for all Steelway products. |

|

After the launch of Steelway's

first pedestrian guard rail in London, a second

installation was carried out on March 22nd, 1935, at

Whitechapel Crossing for the Metropolitan Borough of

Stepney.

Two years later the innovative

Wolverhampton company manufactured the sockets and

detachable uprights to form crowd control barriers for

the 1937 coronation of King George VI - parts of which

were used again for the coronation of Queen Elizabeth II

in 1953.

A letter of appreciation received

after the 1937 coronation from New Scotland Yard reads:

"Now that the coronation is a matter of history, I

should like to express my thanks to your firm for the

efficient way in which you met the demand for barrier

material. As you know the barriers were of unusual

design, which required special attention by you in

manufacture. They proved most satisfactory, and I have

not had any complaints regarding them. This is a matter

of satisfaction to all concerned." |

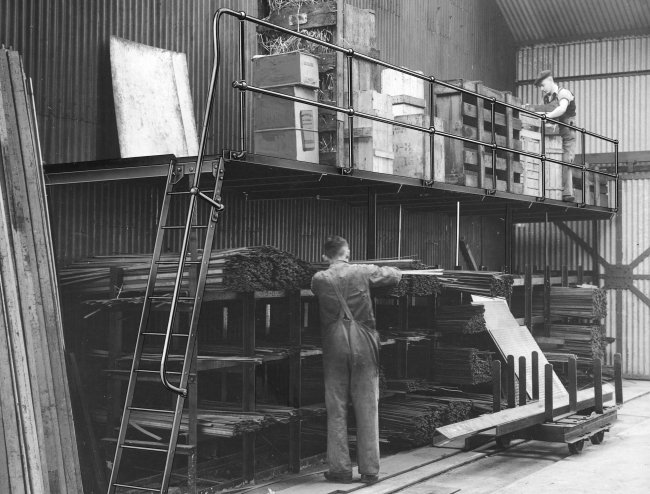

A member of staff at work with a

Steelway trolley at the Steelway site on Bilston Road. |

|

A St John's Ambulance visit to the

factory, probably to see the firm's stretcher design. |

|

A pioneering enterprise in

industrial metalwork access, Steelway became well known

and highly regarded for its flooring, ladders, stairs,

handrails, guardrails, and platforms. It continues to be

held in esteem for such products.

During the Second World War, it

went over to war work and was involved in the

manufacture of stretchers for injured personnel and was

a member of the National Scheme for Disabled Men. Many

of the workers who left to fight in the war effort

returned to their original positions with the coming of

peace.

Eight years after the war ended,

Steelway became a subsidiary of the Glynwed Group of

companies and went on to provide open mesh flooring to

the Z Cars series stage sets and grating to the James

Bond films ‘On Her Majesty's Secret Service’ and

‘Diamonds Are Forever’.

Specialist

Then in 1983 the company expanded

to form Steelway Fensecure. Fensecure itself traces its

origins back to 1918 when John Knowles (Wednesbury) Ltd.

was started by B. C. Knowles and J. J. Knowles.

Unsurprisingly for a Black Country town that was famed

as "Tubetown", the firm was a manufacturer of tube

fittings. However it was not until John Knowles was

bought out by Tipper Brothers in the 1960s that

Fensecure really came into its own. Using the tube

fittings of which the company was a specialist producer,

the classic range of tubular fencing systems was born.

From there, Fensecure soon became one of the country's

leading fencing manufacturers, a position which it still

holds proudly. |

|

Racks of raw materials await

transformation in this picture taken inside one of

Steelway's buildings. |

|

After a number of ownership changes,

Steelway Fensecure became part of the Brigam group of companies

in 2005. Two years later it acquired Brickhouse Access Covers of

West Bromwich, now called Steelway Brickhouse (Steelway

Fensecure Ltd.).

Today this is one of three operating

divisions. The other two are Steelway (incorporating Rail and PP

Mackindale) and Steelway Fensecure. With a plant each in

Wolverhampton and West Bromwich and over 175 workers, these

divisions emphasise the ongoing importance of high quality

manufacturing in our region.

From making metal flooring, walkways,

railings and stairs for waterworks, nuclear power stations,

railways and factories, to carrying out spectacular restoration

projects like the rebuild of a century-old Great Western Railway

turntable as the centrepiece of a visitor attraction in Minehead.

Steelway's products all have one thing in common: they are made

to the highest standards in the Black Country. |

|

Return to

the

previous page |

|