A letter from T. W. Parker that was sent

to his grandson, Charles Parker. Courtesy of Peter Parker. |

A transcript of the letter

on the left, that was written by Thomas Wheatley Parker, and

sent to his grandson Charles Parker, in June 1889. It describes

Thomas Parker’s early career: Your

father left home when he was about 18, and after working and

tramping about the country for several years, came to work by me

on the 2nd

December 1867. Went to the lower works on the 26th August

1868, left on the 10th October, 1874, went to Birmingham on the

13th and to the old Union Mills

on the 14th. Left on the 21st

April, 1875, began again at Coalbrookdale on 3rd May 1875,

left on 7th October, 1882, went to Wolverhampton. Your father

will be able to judge between the above dates, when he made the

lathe and pump and grate. The driving wheel for the lathe was

cast on the 4th

August, 1868, the day on which Strethill Farm was burnt down.

I went to see it, and it could not be cast ‘till I came back. It

was cast in the cellar.

Signed T. W. Parker |

|

By 1875 the family had moved to "The Laurels", which was nearer

to the Coalbrookdale Company's offices and Alfred and Annie were

born there.

At the

time, the Coalbrookdale Company where producing elaborate

stoves and fireplaces, domestic ironware and a rapidly

increasing range of rainwater and soil goods, such as

gutters, drainpipes and gratings.

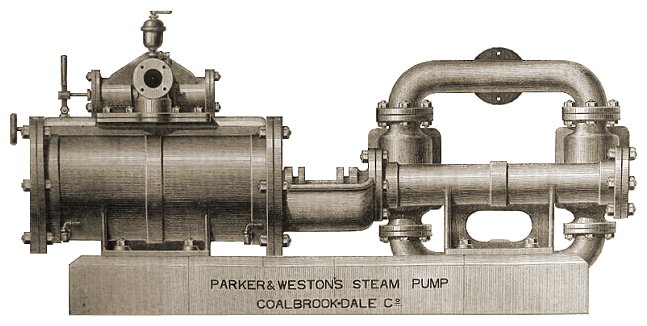

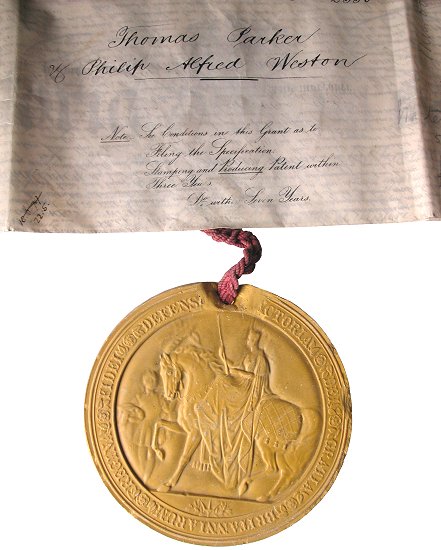

The company also produced

high pressure pumping engines, and in response to this,

Thomas, in collaboration with Philip Weston, invented the

Parker and Weston Patent Steam Pump in 1876.

This was Thomas's first major invention, which was manufactured

exclusively by the Coalbrookdale Company and sold throughout

the world. Philip Weston was a machinist at the works and he

and Thomas took out two patents for the pump. By

1881, Philip Weston, who was 52 years old and lived at Woodside,

Madeley, had become manager of the iron foundry.

Eight years later they were presented with a medal for the

invention, at the Inventions Exhibition in London. This was

the first of Thomas’s many inventions to receive any

recognition and he attributed this presentation as his real

start in life.

|

Thomas, on his return to Coalbrookdale.

Courtesy of Gail Tudor. |

Courtesy of the library and archives of the Ironbridge Gorge Museum, Coalbrookdale.

| |

|

Read a detailed description of

the

Parker and Weston steam pump

from 'Engineering' magazine |

|

| |

|

The valve arrangements in the Parker & Weston pump

were used in all of the Coalbrookdale Company's pumps in

1878, as can be seen from the small section of an

article that follows. This is part of a series of articles

in 'The Engineer' describing some of the exhibits at the

1878 Paris Exhibition:

|

The Engineer,

19th July, 1878. The Paris

Exhibition

Direct-acting steam pumps are

exhibited by several makers, the

Coalbrookdale Company making a

good show of different sizes of

ram and plunger pumps, some

fitted with a condenser and

others with an arrangement of

adjustable cataract, by which

the pump may be made to work

exclusively through any desired

range above half stroke….

….The company exhibited some of

their pumps in action pumping

tar, and capable of pumping

pottery slip or slurry; and a

direct acting blowing engine for

forges, cupolas, and for

ventilating. This consists

simply of the steam cylinder of

the direct-acting steam pump

with the pumping cylinder

replaced by a blowing cylinder,

surmounted by a large air

vessel. This, like all the pumps

exhibited, is fitted with

Messrs. Parker and Weston's

patent direct-acting pump valve

arrangements. |

|

|

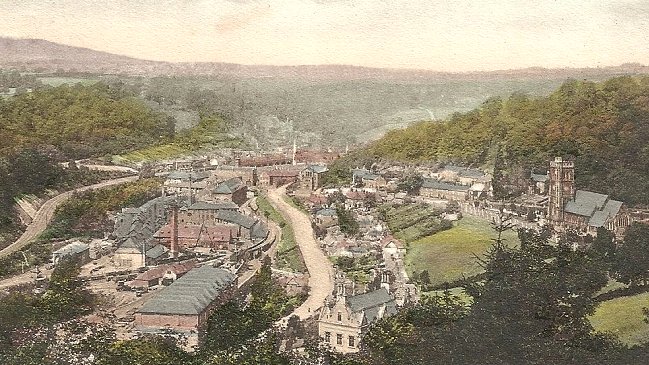

Coalbrookdale in Thomas's time. From an old

postcard.

The patent grant and the seal for the

Parker Weston steam pump. Courtesy of the library and archives

of the Ironbridge Gorge Museum, at Coalbrookdale. |

In about 1878 he designed and built a large dynamo for the firm's electro-plating department. The art casting

department at the works used electro-deposition of bronze and

copper finishes on a large scale.

The electricity previously

came from huge battery cells, which would have needed a lot of

maintenance and only supplied a limited amount of power.

This must have been one of the first dynamos in

the country to be put to a practical use, and one the first to

be used for this purpose

in the world.

The Coalbrookdale Company turned its attention to smoke

abatement and introduced the Iron Bridge series of grates.

Thomas also considered the problem and invented the "Kyrle" open

grate, which was the first open grate in which

anthracite coal could be burned.

|

An advert for Thomas Parker's "Kyrle"

grate. It was manufactured by the Coalbrookdale Company.

Courtesy of Peter Parker. |

| The "Kyrle" grate was probably named after John Kyrle,

an English philanthropist who lived in Ross-on-Wye, and

devoted his life, and his wealth, to the greater good of the

community, and the local area. At the time when the grate

was developed, the Kyrle Society, founded in 1876 was making

a name for itself by bettering the life of working people,

and encouraging the development of parks, and gardens. The grate was added to the Coalbrookdale

Company's list of products, and in

1881, after official testing by the Smoke Abatement Committee

of the International Smoke Abatement Exhibition, at South

Kensington, he was awarded the Exhibition's Silver Medal.

At about the same time he invented a gas engine, known as

“Robinson’s”. It was made by Tangye Brothers of Birmingham. |

|

Thomas at the age of 32.

Courtesy of Gail Tudor. |

In 1859 the lead-acid cell was invented by

the French scientist, Raimond Louis Gaston

Planté. Thomas began to make his own accumulators, as the cells

were called, and began to cooperate with Paul Bedford Elwell,

who ran the Patent Tip and Horseshoe Company in Wolverhampton.

This work led to a patent being taken out in 1882, by Thomas

Parker, in conjunction with Paul Bedford Elwell, for an

improvement to Planté’s original design, which greatly increased

the capacity of the cell. In their process the lead plates for

the battery were first put in a bath of dilute nitric acid and

sulphuric acid, and left there for 24 hours. The effect of the

bath was to minutely honeycomb the lead plates to form what was

called "spongy lead".

This greatly increased the surface area of

the plates and hence the capacity of the battery. A deposit of

lead sulphate also formed on the surface, which was subsequently

reduced to peroxide, and part of this was washed off before use.

Strangely enough, M. Planté, the original inventor, applied for

a patent for the same process on the same day, and ultimately

two separate patents were granted to the rival claimants, by the

Solicitor-General. Elwell and Parker later purchased M. Planté's

interest in the process.

|

|

The Coalbrookdale Institution. As it is

today. |

|

Thomas took out several patents for improvements to alternators,

and in 1881 was involved in the electric tramway at Portrush, in

Northern Ireland. This was the first electric tramway in the

world to be powered by hydro electricity.

Thomas was very interested in politics and became an

enthusiastic supporter of the Liberal cause. This was possibly

because of his upbringing in Coalbrookdale where the Darby

family were staunch Liberals. Thomas joined the Liberal Party

and became a member of the Executive Committee of the Borough of

Wenlock Liberal Association.

|

|

The old Coalbrookdale foundry

site. As seen in October 2019. |

|

He used to lecture at the Coalbrookdale Institution, and on

Tuesday, 9th February, 1882,

gave the first successful demonstration of Swan and

Edison’s incandescent lamps3.

There were seven lamps, which were run from two Parker storage

batteries. The lamps ran for fifteen minutes and provided 20

candlepower, and lit the room nearly as well as the 18 gas jets

that were usually in action.

In June 1882, Paul Bedford Elwell and Thomas Parker jointly

registered a patent for "Improvements in dynamo electric

machines",

and in August they took out another patent for "Improvements in

electric lighting and apparatus associated herewith".

Thomas decided to join forces with Paul-Bedford Elwell, in

Wolverhampton, to form the first company in the Midlands to

manufacture electrical equipment. He left Coalbrookdale in

October 1882 and moved to Wolverhampton.

|

|

Read

about

Thomas's farewell

to Coalbrookdale |

|

|

|

Return to

the beginning |

|

Proceed to

Elwell-Parker Ltd. |

|