My time at the company

|

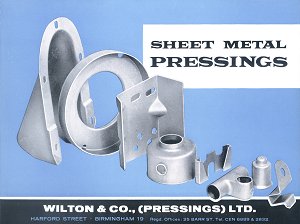

I joined the company in 1955 after serving an

apprenticeship in the Press Tool Design Office of Nuffield Metal

Products. My first position was to establish a Tool Design Office and to

run the toolroom. In December 1960 I was appointed to the Board as the

Works Director.

The factory was expanded again in 1963 by building over

the area formally occupied by the two retail shops. This enabled a

modern Metal Shearing Department and steel stores to be constructed.

On the 20th July 1960 my mother, Mabel Rollings, died

suddenly after a short illness. She had served as a Director of the

company for 25 years and had been Company Secretary since 1968. This

left a gap which was hard to fill. My wife, Sylvia Rollings and Mr Jeff

Gillett, our former accountant, took over her post and became Directors

of the company.

|

|

In April 1969 the company was dealt another blow.

My father, Harry Rollings, left the office at 4 pm to go to play

golf at Moor Hall Golf Club. I had a telephone call to say that

he had been rushed to hospital after suffering a heart attack.

When I arrived the hospital he was dead.

After my father's death I took over as Chairman

and Managing Director.

My family and I went through two years of extreme

difficulty, horrendous death duties being levied on us. We

managed to pay off the death duties without having to dispose of

any of the company's assets. |

| During the next twenty years we went from strength to

strength. A second factory was purchased which was located just along

the road from our Barr St./ Harford Street Works, on the corner of Great

Hampton Row and Barr Street.

We became the first Quality Assured small

presswork supplier to the Austin Rover and Land Rover groups and right

up the present time we have an ISO 90002 Quality Rating, thus continuing

that high standard of quality. |

|

|

In 1982 our elder son, Steven Rollings, joined the company

and ultimately became Works Director.

In the late 1980s the company was employing 70 people.

Trading with the motor industry started to become very difficult, with

the introduction of "just in time" deliveries. Suppliers were having to

pay the storage charges for the motor companies' stock, whilst it was

held by an independent storage company.

|

| The invoicing was controlled by

the customer on a self invoicing basis. This effectively meant that if

their production dropped you would not get paid until the next time of

withdrawal. Further to this the storage costs were estimated on 12

months' full production, which was rarely achieved. This meant we were

paying for storage when it was not being used. We were unable to obtain

price increases at the rate of inflation on an annual basis, steel

prices kept going up and margins were eroding. |

| They then came along

requesting that the price go down by a percentage each year. At this

point we decided enough was enough. The large motor companies were told

we would be closing the company in two weeks. As a result of this they

found a company, A. J. Williams Limited of Tamworth, to take us over. We sold

the order book, the work force, the plant and machinery, and the name

Wilton & Company (Pressings) Limited.

The two properties and the old company,

with its name was changed to Rollings Holdings Ltd, were retained. If we

had left it longer we would have finished up with nothing other than the

value of the plant. |

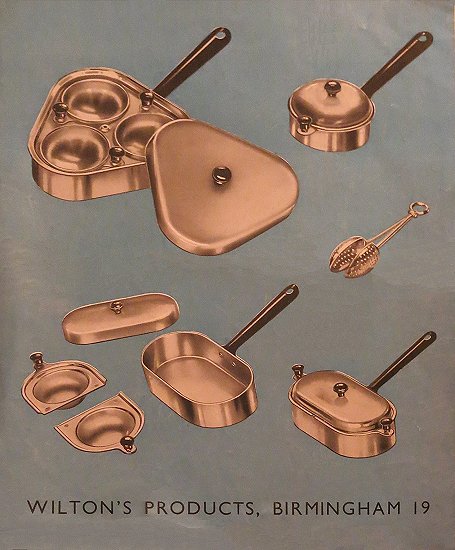

Egg Poachers. |

|

Just after the time of the takeover of the company by A.

J. Williams Ltd., Steven Rollings left and went to work with three

different engineering companies over the period of five years. In the

first company he was the Production Manager and in the later two was the

Works Manager. Rollings Holdings Ltd. continued trading by dividing the

premises into small industrial units and letting them. As part of the

sale agreement I was not permitted to trade as a press work

manufacturer. It was decided to establish a press toolmaking company.

This was not easy at first as a new customer base had to be established.

After five years it was trading very successfully. So Steven returned

and took over the engineering side of the business and has taken it from

strength to strength despite very difficult trading conditions in the

engineering industry.

|

|

|

|

|

|

Return to the

previous page |

|

Return to the

contents |

|

Proceed to the

next page |

|