|

The

story of a successful company that has its roots in

Wolverhampton

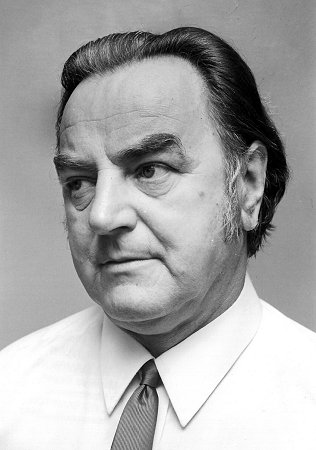

Albert Douglas (Doug) Barker, born in 1917,

recalled this period of his life as Managing Director

of Cab-Craft Limited to his son John, and daughter

Julie, leading up to his 93rd birthday.

|

| Beginnings and Growth I recently read with great interest Charles Weight's

account in the Wolverhampton Museum archive about the

early years of development of tractor cab manufacturers

based in and around the Wolverhampton area. However, the

penultimate sentence in his story is a bit misleading in

that Cab-Craft Limited - then owned by their factory

landlords: the David Charles Group - actually went on to

acquire his larger Tractorvision company at Four Ashes.

This was shortly after David Charles invited me to join

Cab-Craft Ltd. as Managing Director at their Penkridge

works - replacing Dave Thomas in 1967. I held that post

up to my retirement due to ill health in 1977.

My first

task at Cab-Craft was the urgent need to improve

productivity which I did by employing an inspector/rate

setter and introducing a fair to both sides piece-work

incentive bonus.

The scheme was modelled on one I had

recently devised when I set up the production line for

ISO freight containers at Metropolitan Cammell. The shop

floor workers immediately enjoyed substantially higher

wages and the finished cabs rolled out of the door at a

much faster speed. |

Doug Barker. |

| When we first took it over, the TractorVision

factory was owned by the Caterpillar Distributor Bowmaker Plant. It

was a loss making, union organised factory with a history of poor

industrial relations. We bought the business because we urgently

needed more production and storage space as we had outgrown our

factory. The smaller plant at Penkridge was non union, making good

profits and was becoming increasingly restricted by small premises

with no external area for holding stock.

The factories were four

miles apart, both located on rural industrial estates between

Wolverhampton and Stafford and were run as two separate production

operations but with common use of the design and purchasing

facilities in the Four Ashes office block. Head office (including

Sales and Accounts) remained at Penkridge. Over the years, the two

shop floor workforces continued to refuse to co-operate and I

reached the conclusion that they would never have worked

harmoniously in one large factory. I soon introduced the same

piece-work scheme which had proved so successful a year earlier at

Penkridge and within weeks, this factory was also returned to

profitability. I was now confident that we could

build-up the business using internally generated

income helped by the David Charles Group who supported

us strongly in the early stages of growth. |

| Fuelled by tougher U.K. Health & Safety

legislation, the 70's decade saw a huge development in the market

for safety cabins for tractors, combine harvesters, earthmovers and

handling trucks. Cab-Craft grew rapidly to become the dominant

player in the U.K. cab industry (there were 5 other companies

contesting the market at that time) and we enjoyed a fine record of

annual growth and profitability under my stewardship.We also became

substantial exporters too shipping cabs to Ireland, Scandinavia and

several other countries around Europe. My skills in welded

fabrications and more latterly in selling combined well with our

design & development team. We formed a prototype unit and designed

many well-styled cabs which looked to be an integral part of the

machine. Dealers and end users liked our designs and the business

thrived and grew. So Charles Weight's final 'amen' to Cab-Craft in

his Tractorvision archive was somewhat premature! The final 'Amen'

was to come a decade later. |

|

An Allen grass cutter fitted with

a Cab-Craft cab. |

Over 10 years, I built the Cab-Craft business

from well under £1m annual turnover to over £5m annual turnover, with year-on-year increases in net profit, culminating in over £1m

net profit in1975/6.

My son John Barker joined the business as Sales

& Marketing Director in 1974 with agreement by David Charles for him

to take my position as M.D. after 6-months. John developed and

agreed a ten year plan with Group to diversify the

business to keep the company healthy when the

independent cab business started its inevitable decline.

But by1975, we became increasingly worried about the

desperate cash shortage within the parent Group. We were

able to help and following an excellent 1976/7 financial

year, we forwarded a record £1.1 million net profit to

our owners. |

| Imagine our dismay when 6-months later - the banks

insisted on the appointment of their nominated Director

to the Group's Board shortly afterward. All the

Directors of subsidiary companies were called in to Head

Office to meet him - where we received his assurance

that his bank would see them through their temporary

cash flow crisis. A few weeks later, they forced the

Group into Receivership/liquidation and closed-down many

of the Building Division companies. Cross guarantees

right across the Group saw the Receivers Cork Gully

coming in to all the profitable companies - us included

- to immediately manage our business. To our surprise,

they waved their cheque book at us and we returned to

full production the following day. |

| As we were still a

rising star, we received financial backing paying cash with order to

all our suppliers. Six months later, we were put up for sale as a

debt free going concern. We spent 6 months being interviewed by

several prospective purchasers and against all the odds were

snapped-up on the last day for sealed bids by the Mitchell Cotts

Group, who operated a large warehousing complex adjoining the Penkridge

factory.

They paid £1.2 million for the business. Arguably an

overly generous sum for a low asset company such as ours

working in three rented properties.

They were looking to buy a successful farm machinery

manufacturer and had very little time to carry out

due diligence enquiries. |

A Clark tractor

equipped by Cab-Craft, is dwarfed by a Jumbo Jet at

London's Heathrow airport. |

| We were employing 340 people at the time and working

two shifts out of our 3 factories, and building several

thousand very sophisticated safety/quiet cabs each year,

including the insulation and fitting of our newly

developed cabs on to all new Massey Ferguson 240/265

series tractors sold in the UK, in a new assembly

factory we had very recently rented in Shaw Lane,

Wolverhampton.

I am proud to say that nobody lost their job at that

time and the Directors and staff all received generous

contracts of employment at 'terms no less favourable

than previous'. My only regret was that because of Group

cross guarantees to maximise their borrowing facility

our key suppliers lost a lot of money as there was no

creditors payout after preferential creditors had

received their dues from the Group.

I was due to take early retirement that

year, and I personally lost a small fortune as all my profit related

bonuses went into buying David Charles Group shares, with a face

value worth over £250,000 the year before the property market and

land values collapsed, which resulted in the building Group's

failure.

This was a bad time for me and my health deteriorated

rapidly. David Charles was a good house building company holding a

very large high value land bank at the wrong time. Within 9 months

of the liquidation of the central business, land values recovered to

record levels, and so another good Midlands company bit the dust

for the sake of not receiving short term support from their bankers

(there was no quantative easing in those days).

Mitchell Cotts

actually agreed to buy Temperate Filtration Limited, a key supplier of

air filtration units, as we were their main customer and we needed

continuity of supply. So Cab-Craft Limited became part of the Mitchell Cotts Engineering Division, headed by the then M.D. Dennis Hands.

They were not too familiar with the fast pace of the sheet

metalworking sector, but they soon came to realise that our working

practices were quite different!

To their credit, they invested in

our business by agreeing to the purchase of an N.C. automatic punch

press, an N.C. back-stop controlled press, and freed-up a

neighbouring warehouse at Penkridge to bring production potential up

to the level of the Four Ashes site. |

A Massey-Ferguson 40 digger loader fitted with

a Cab-Craft safety cab.

|

I had a great team at Cab-Craft who played a

large part in the development of the business. It is an interesting

story, so I thought it worth recording in the archive. It was the

most satisfying post I ever held because we must have saved many

lives as well as dramatically improving the health and life span of

many farmers and their workers. I will always be proud of that

achievement.

Here's a summary of what we

achieved together, thanks in particular to Peter York

(Technical Director), John Barker (Sales & Marketing

Director), Graham Bustin, and Ron Baldwin, who all

worked so enthusiastically to meet the development

challenges of a rapidly developing market. We became top

dog in the industry because over 75% of our products by

value were sold directly to dealers and end users. In

this way, we controlled our marketing and pricing

without allowing manufacturers to push prices downward.

This proportion was to reverse over time as the vehicle

manufacturers wanted and obtained a larger slice of this

business.

To the best of my knowledge, we never received

any acknowledgement or award from the Government, the N.I.A.E, or

the N.F.U. for our pioneering health and safety work. I do recall

reading in the Birmingham Post that 3 or 4 people working for the

National Institute of Agricultural Engineering received awards in

the New Year Honours lists for their work in developing safety cabs.

Their contribution was mainly to develop a cab testing procedure. It was the cab companies, like us, that did all the development

work on the safety frames and on the noise deadening work.

More

important than awards, we were always very pleased to receive the

thanks and best wishes from thousands of farmers (and particularly

from their wives) when we met them at the various Royal and the

Smithfield Shows. They were thankful for our dramatically improving

working conditions and keeping their husbands and sons safe and

well. At that time, fatal accidents on farms were running at an

all-time high, and lung disease amongst older farmers was also

emerging as a slow killer, rather like pneumoconiosis in the mining

industry. |

|

|

|

Return to the

engineering hall |

|

Proceed to Combine

Harvester Cabs |

|