|

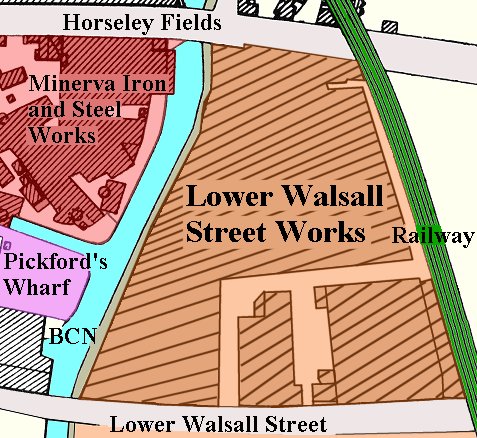

Lower Walsall Street Works

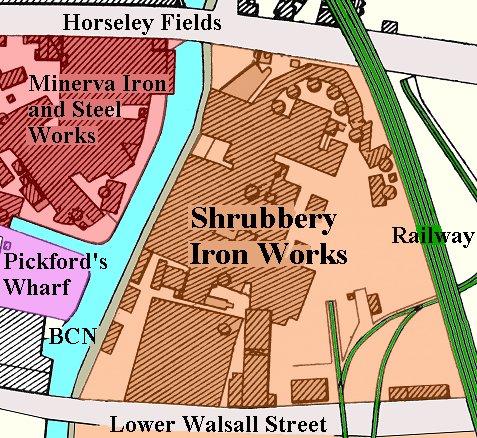

In 1824 the site was occupied by the northern half

of the Shrubbery Iron Works that were founded by

George Benjamin Thorneycroft and his brother Edward.

The company became very successful, but began to run

at a loss due to the recession in the 1870s. The

company closed in December 1877, the closure being

blamed on the higher wages that were paid to the

workforce. The northern half of the works are marked

as disused on the 1888 Ordnance Survey map, and appear to have

remained in a derelict state for many years.

|

Read about

Shrubbery Iron Works |

|

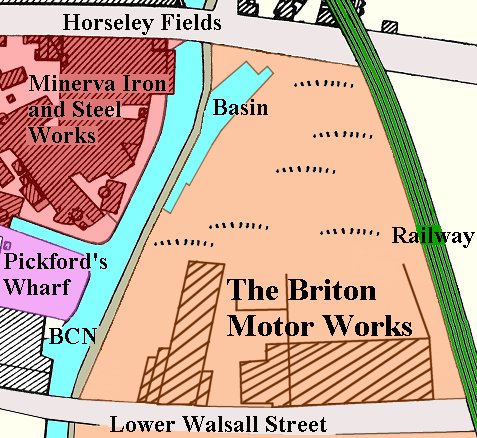

The site at the beginning of the 20th

century when the Shrubbery works were derelict.

| The Briton Motor

Company Limited Background

In 1905 the Star Cycle Company began to produce a

low-cost range of cars, initially under the

‘Starling’ name, adding a ‘Stuart’ model a year

later. Star already produced high quality, expensive

cars which were manufactured by the Star Engineering

Company. In 1909 this company took over its parent

company (The Star Cycle Company) and the manufacture

of ‘Starling’ and ‘Stuart’ cars ceased. They were

replaced by the Briton Car Company under the

direction of Edward Lisle Junior, the son of Star's

founder.

Briton started life in the company’s Stewart

Street Works where the ‘Starling’ and ‘Stuart’ cars

had been built. The same workforce was employed,

and the first model, the 10hp. ‘Little Briton’ soon

appeared.

In 1912 the company purchased the six acres of

land between Lower Walsall Street and Horseley

Fields that were previously occupied by the northern

half of Shrubbery Iron Works, and built a new

factory on the site. |

The works as built.

Lower Walsall Street Works in 1915.

|

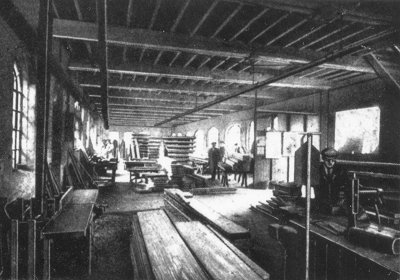

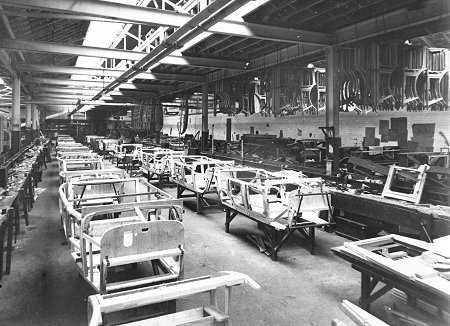

Woodwork Department. |

|

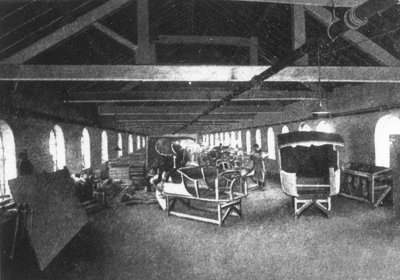

Body

building. |

|

|

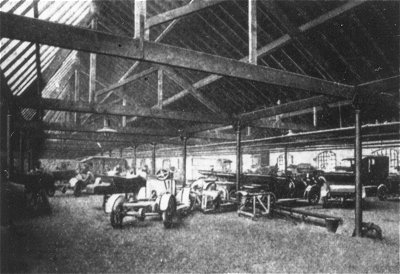

Assembly. |

|

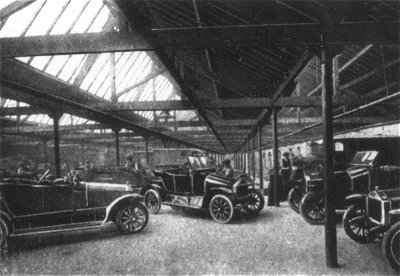

Final

assembly. |

|

| Production moved to the site in 1913. During the

First World War car production continued until 1917,

when some ambulances and large commercial vehicles

were produced.

Products from the 1915 catalogue |

|

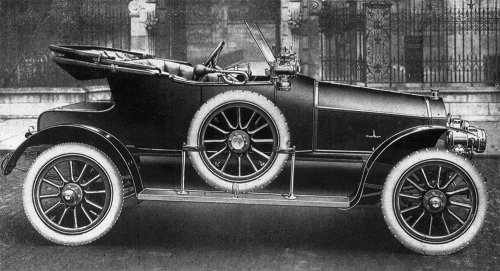

The 2 seater, 4 cylinder

de luxe 14-16hp. Britain that sold for 330 Guineas. |

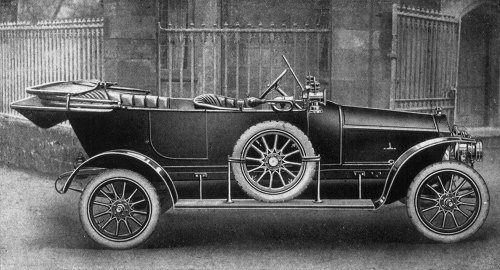

| The 4 seater, 4 cylinder

standard 14-16hp. Britain that sold for 240 Guineas. |

|

|

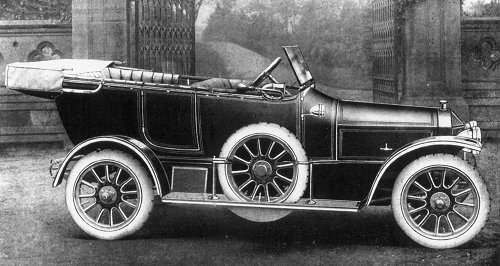

The 4 seater, 4 cylinder

de luxe 14-16hp. Britain that sold for 370 Guineas. |

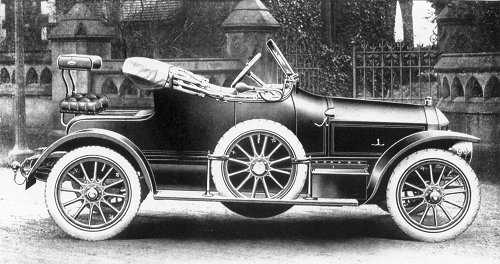

| The 2 seater, 4 cylinder

standard 14-16hp. Britain that sold for 220 Guineas. |

|

|

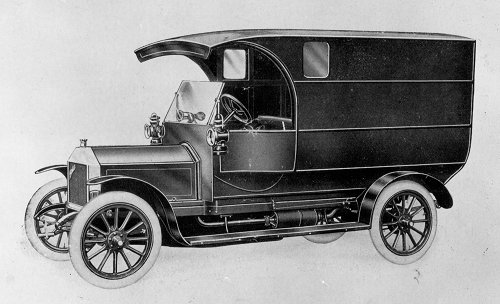

The Briton 14-16hp. 4

cylinder Light Delivery Van that could carry 15cwt.

and sold for 220 Guineas. |

Car production resumed in 1919, but by this time

the larger car manufacturers had adopted mass

production techniques, and the price of their

products fell. Briton could not compete in this new

market, and in 1921 production fell to just 65 cars.

In December of that year the company ended-up in the

hands of a receiver, and in January 1922 a

liquidator was appointed. On 3rd October

the works were sold to A. J. Stevens & Company

(1914) Limited and a new chapter began.

| Read more

about Briton Cars |

|

A.J.S.

Background

The 4 Stevens brothers, Harry,

Joe, Jack and George decided that they wanted to

produce motorcycles, having gained a lot of

experience in engine manufacture. On November 1909

they founded A. J. Stevens & Company (1909) Limited

with a share capital of £1,000. They decided to

produce motorcycles under the A.J.S. name which came

from Jack Stevens' initials, which were chosen

because he was the only one of the brothers to have

two Christian names, Albert and John. The company

had a small premises in Retreat Street, on the

corner of Penn Street.

Harry Stevens, the company’s

designer, quickly developed their first machines,

which proved to be very successful. The company

quickly made a name for itself by entering machines

in competitions including the Isle of Man T.T. which

resulted in a great demand for their products.

Because of the small premises, its limited

manufacturing capability, and cramped conditions,

they found it difficult to build enough machines to

keep up with the demand. Production had to be

increased and so a larger premises was essential.

To achieve this, additional

finance would be required, and so they formed a new

public company called A. J. Stevens & Company (1914)

Limited, with a nominal share capital of £50,000.

The directors were H. Stevens, G. Stevens, J.

Stevens, A. J. Stevens, E. E. Lamb, and E. L. Morcom.

The company purchased Graiseley House and the

surrounding land on Graiseley Hill and over the next

few years a large factory was built which had some

of the most up-to-date machinery in the area.

Success continued and large numbers of their popular

motorcycles were produced each year.

| Read more

about A.J.S. |

|

Sidecars

A.J.S. also built sidecars in

their Stewart Street Works run by Charles Hayward.

The business thrived, producing sidecars for most of

the major manufacturers including Sunbeam. It became

the largest sidecar manufacturing plant in the

world. The sidecars sold extremely well and Stewart

Street works couldn't keep up with the demand. The

company decided that production must be increased,

and so larger premises had to be found. As a result

A.J.S. purchased Lower Walsall Works for £7,000 on 3rd

October, 1922 and sidecar production soon moved

there. Over the next few years new buildings were

added, and the factory grew to cover the whole site,

looking much as it does today. |

The works in their final form.

The A.J.S. Works.

|

The Frame Erecting Shop. |

|

The Wheel

Assembly Shop. |

|

|

The Sidecar Erecting Shop. |

| The Sidecar Finishing

Shop. |

|

| Sidecars were produced for a large number of

motorcycle manufacturers and they continued to sell

extremely well until the emergence of the light car

in the mid 1920s. The A.J.S. Board decided to offset the

falling sales by introducing a range of commercial

sidecars that were aimed at door to door delivery or

service work. The new products included a fire

fighting sidecar with a Merryweather fire pump,

ropes and axes, and also a prototype lightweight,

collapsible caravan which never went

into production. In September

1930 the company began to use the

'Graiseley' brand name for its

sidecars. They were supplied to

manufacturers, and for the first time to motorcycle

dealers, so that they could be fitted to almost any

make of machine.

| Read more

about A.J.S. sidecars |

|

|

|

The Internal Timber Store. |

|

The Wood

Mill. |

|

|

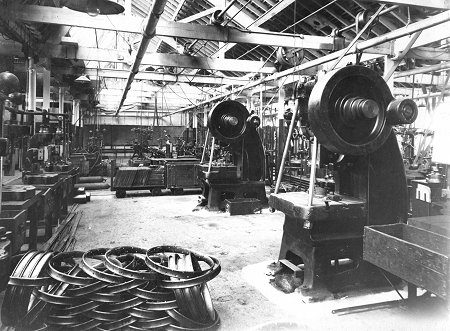

The Blacksmiths Shop. |

|

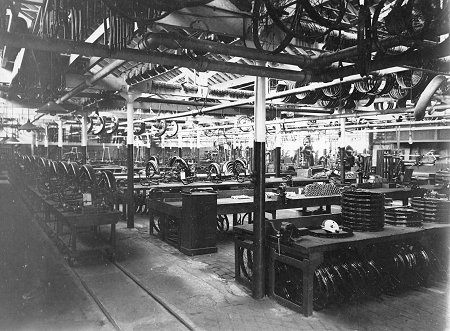

The Machine

Shop. |

|

|

Wireless Receivers

In the early 1920s radio became

a popular form of entertainment, particularly after

the formation of the BBC in 1922, and the regular

broadcasts that began before the end of the year.

Harry Stevens’ main hobby was amateur radio, and he

convinced the company that they should begin to

manufacture wireless receivers to cater for the new

and increasing demand. The receivers would be built

at Lower Walsall Street Works and new buildings were

added for the wireless department.

Harry soon designed a 4 valve

receiver, and several models were launched in the

autumn of 1923, all aimed at the top end of the

market. The cheapest model, the 'Sloping Panel' sold

for £30.17s.6d. and the top of the range model, the

'Pedestal', housed in a free standing cabinet, with

internal horn loudspeaker, sold for £75. By October

1923, 500,000 licences had been issued and A.J.S.

receivers sold well and were gaining a reputation

for quality and reliability.

A new range of receivers was

launched in 1924 featuring a greatly improved

design, and A.J.S. opened its own radio station,

broadcasting from the works, using the call sign 5

R.I. Most of the programmes consisted of music,

presumably as a way of helping to sell the

receivers.

An A.J.S. type 'F' from 1924.

In 1925 part the wireless

cabinet making department moved to the company’s

Stewart Street works because sales were very high

and extra space was required to increase production.

A new sound proof demonstration area was also added

at Lower Walsall Street, so that dealers could see

the new receivers working in ideal conditions. New

showrooms and offices were opened at 122-124 Charing

Cross Road, London, and dealers were appointed in Australia, New Zealand, India, Siam and

South Africa.

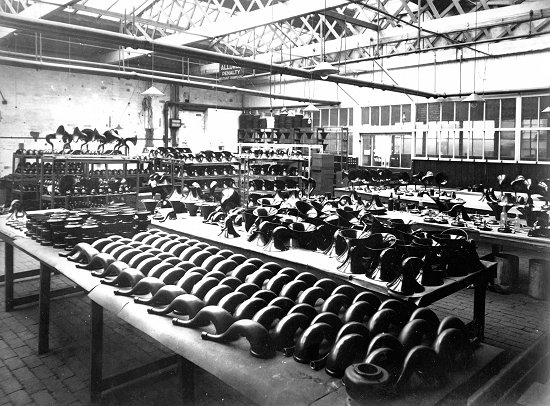

The Metal Horn Loudspeaker

Shop.

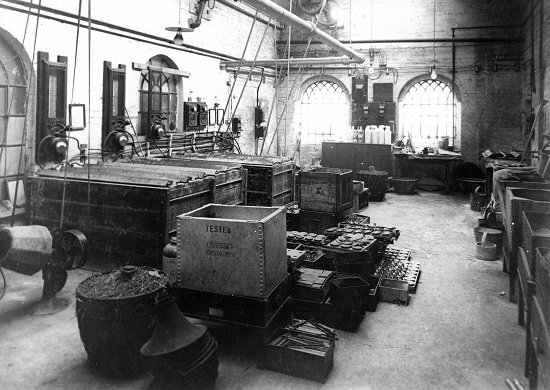

The Electro Plating Shop.

Nickel plating loudspeaker components.

Things continued to go well

until the following year. By 1927 sales had started

to fall due to increased competition, and the

remaining parts of the Wireless Department moved to

Stewart Street Works. Sadly things didn’t improve

and wireless production ended in the summer of 1928.

| Read more

about A.J.S. wireless receivers |

|

Car Bodies

In the summer of 1927 A.J.S.

secured a lucrative contract to build bodies for the

new Clyno 'Nine' light car. The contract couldn't

have come at a better time for A.J.S. because

motorcycle sales were in decline due to the

depression and the introduction of cheaper small

cars. The bodies consisted of a wooden framework

that supported fabric covered panels and were built

in batches of 50. They were made at the Lower

Walsall Street works.

In its heyday Clyno was the

third largest car manufacturer in the country, and

large numbers of the car bodies were produced,

becoming an important addition to the A.J.S. product

range. In 1928 the whole A.J.S. sidecar range was

also covered in the same material.

The orders from Clyno continued

until February 1929 when Clyno went into

liquidation. This came at a very bad time for A.J.S.

who were also loosing money due to lower than

expected motorcycle sales and the demise of the

radio business. To try and offset the loss of the

Clyno contract A.J.S. decided to produce its own

light car, the A.J.S. 'Nine'. The cars were built at

Graiseley Hill and the bodies at Lower Walsall

Street. |

|

The Motor Body Shop. |

| The Motor Body

Panelling Shop. |

|

|

|

The Paint Drying Shop. |

| The Body Erecting Shop. |

|

|

Commercial Vehicles

In 1927 a prototype commercial

vehicle chassis was produced at Lower Walsall Street

and successfully tested with a make-shift coach

body. Nothing further happened until February 1929

when A.J.S. lost its lucrative contract for Clyno

car bodies, after Clyno's closure. The first model called the 'Pilot'

was intended for use

as a long distance, high speed coach but was also

sold for use as a van or lorry.

The chassis consisted of

engine, wheels, axles and all associated parts, the

bodywork was left to specialist body builders. The

main frames were made by John Thompson Motor

Pressings Ltd at Bilston and the engine was a 25h.p.

Henry Meadows 6ERC, 6 cylinder, overhead valve with

a 4 speed gearbox. The top speed was 55m.p.h. and

the basic chassis sold for £685.

A 'Pilot' coach.

October 1929 saw the launch of

the 'Commodore' chassis, a heavy duty chassis with a

10inch deep chassis frame and extra cross members to

evenly distribute the load. The engine was a 36h.p.

Coventry Climax L6, 6cylinder side valve design with

a 4 speed gearbox. The selling price was only £860,

far lower than the competition. Only small numbers

of vans, lorries or buses were built onto the

chassis, and none have survived.

A 'Commodore' coach.

| Read more

about A.J.S. commercial vehicles |

|

In 1931 the company was in

financial difficulties due to falling sales and a

receiver was appointed. A.J.S. went into voluntary

liquidation in October and Lower Walsall Street

Works were put onto the market. They were sold to

Ever Ready on 25th January 1932, for £12,750, and

went on to become an important centre for the

manufacture of torches. The works now became known

as Canal Works.

The main entrance to the Ever

Ready factory.

Every Ready produced items that were

battery-powered and would enhance the sale of their

batteries. They manufactured torches and portable

lamps. The company also had a factory in Park Lane

where they made batteries and portable radios.

Another view of the Ever Ready

works. Ever Ready's Lower Walsall Street

factory closed in the early 1990s. The company went

into liquidation in 1998 and reformed under the name

of Energizer.

The factory as it looks today.

Since Ever Ready's departure the factory has almost

become a small industrial estate and is now occupied

by a number of different companies including BRM

Packaging Limited, Van Smart vehicle conversions,

and 24/7 spares and salvage. |

|

Return to the Canals

and Industry Menu |

|