|

New Griffin Works appear to

have been built sometime between 1842 and 1881. The

factory is not marked on the 1842 Tithe map, but can

be seen clearly on the 1881 Ordnance Survey map.

In the latter part of the 19th

century the buildings were occupied by edge tool

maker William Edwards & Son. The business is listed

in Pigot & Company’s 1842 Directory, and White’s

1851 Staffordshire Directory as being located in

Dudley Road. They also owned Griffin Works in

Horseley Fields, before moving to New Griffin Works. |

An advert from 1891.

What remains of New Griffin Works canal

wharf. As seen from the Wyrley and Essington Canal.

| The next section is part of an article that

appeared in the Wolverhampton and South

Staffordshire Illustrated. Unfortunately the date is

not known. |

|

In the construction of the New

Griffin Works, many features of improvement in

design and arrangement would be suggested by the

long practical experience of the proprietors, and in

our progress through several departments, frequent

evidences of this progressive adaptation of modern

appliances and methods came under our notice.

The new works occupy a most

convenient site in Willenhall Road, covering upwards

of four acres, bounded by the Birmingham Canal on

one side, and close to the Wolverhampton and Walsall

section of the Midland Railway Company. The premises

comprise, in the front portion, handsomely appointed

general and private offices, adjacent to which are

store rooms and the entrance to the large open

quadrangle, round which are ranged the various

substantial buildings devoted to the manufacturing

departments.

On the right and left of the

entrance are four large forging shops, each fitted

with a number of smith’s hearths furnished with

steam blowing apparatus on an entirely new

principle, one portion of the forges being utilised

for the manufacture of horse shoes. The firm are the

original and only makers of the ‘Best Crown’ brand,

a speciality largely supplied to her majesty’s

government. Other brands as shown by the

accompanying Trade Marks are widely known and

esteemed in the home and foreign markets. Spades and

shovels are also one of the special features at

these works.

Trade Marks

At the further end of the yard

are the forging shops in which heavier steam hammers

are placed, some weighing nearly four tons. To bear

this immense weight and consequent concussion, the

floor of these shops has been specially prepared

upon a foundation of some eight or ten feet of

massive logs of timber, concreted on the top.

The engines used in driving the

machinery are of exceptional size and power, and are

fitted with immense flywheels, one of the engines

being served by three enormous boilers, each of 37

feet long.

At the entrance end of the

premises are the grinding and polishing shops,

similar in arrangement to those already described in

the old works (Griffin Works, Horseley Fields). At

both establishments extensive space is allotted to

the warehousing and packing of the firm’s finished

goods, to which our attention is next directed.

Literally speaking Messrs.

Edwards and Son’s manufactures can claim world-wide

utility and favouritism in their many sided

application to the arts of cultivation. Railway and

road-making, and mining and woodcraft operations,

for which they are exclusively designed. Without

entering upon a fully detailed description of the

numerous range of articles of their production, we

may present particulars of the more representative

types of edge tools, which offer special features of

interest to the trade. In implements of cultivation

there are, perhaps most widely known as the

inventors and makers of the ‘Royal Express’ hoe,

which has almost entirely superseded the old

‘Brazil’ iron hoe, with its shoulders more than half

an inch thick, and its blade 11 inches wide.

The firm also make an improved

type of wrought-iron wheel barrow, with steel bodies

constructed in parts, which are put-up in handy form

for packing for the export markets, that they may be

easily put together again when landed at their

destination.

Messrs. Edwards & Son have long

since met with justly merited recognition at some of

the principal industrial exhibitions of the century,

their record including the award of a first class

certificate and silver medal for their edge tools,

spades, shovels, hoes, and horse shoes at Calcutta,

1883-84. Two first class certificates and highest

awards at Liverpool International Exhibition, 1886,

while their handsome and attractive stand at the

more recent Wolverhampton Fine Arts and Industrial

Exhibition obtained the highest award in its own

particular section. |

|

In 1913 New Griffin Works were

purchased by the Vulcan Manufacturing Company, owned

and run by the Waine family. Joseph Waine & Co. Ltd, general

lock, latch & bolt makers, and brass and iron

founders was located at Imperial Works, Wood Street,

Willenhall. Joseph had three sons, John Vincent

Waine, G. A. Waine and Horace T. Waine.

John Vincent Waine, and his

brother G. A. Waine, started the Vulcan

Manufacturing Company at Blackheath, Birmingham, in

about 1910. The company manufactured Heel Tips, Toe

Plates and had the most up to date machinery in the

world. The factory turned out 288,000 pairs of heels

per week, under their Vulcan brand name. The

company specialised in a number of products

including No. 0 and 1 York heels, 21B heels, mule &

horse shoes for the Indian, Turkish, African and

South American markets, and japanned and galvanised

door bolts. A large number of other products were

produced including the following:

Brass -

chromium-plated or with

special finishes, stainless steel, garage bolts,

cabinet bolts, japanned or galvanised door bolts, shelf brackets, aluminium door and

gate latches, door stops, casement stays and fasteners, hasps

and staples, hinges, brass and steel gate and tee,

gutter brackets, swivel ties, tinned angle brackets,

rim, dead and mortice locks, latches, padlocks,

stamped brassware, and household soldering sets.

The works covered over an acre.

Extensive trade was done with the War Office, the

Army and in various parts of Europe. Horace T. Waine

was also involved in the business, and due to his

international travels the products were also sold in

Japan, Burma and Egypt. The company also had an

establishment in the Potteries.

In 1913 the Directors decided

to move the three factories to one site to improve

the company's efficiency. In June New Griffin Works

in Colliery Road, Wolverhampton was purchased, and

the three factories were combined under one roof. At

the time New Griffin Works was empty. The factory

backed onto the Wyrley and Essington canal so that

narrow boats could be loaded and unloaded. |

|

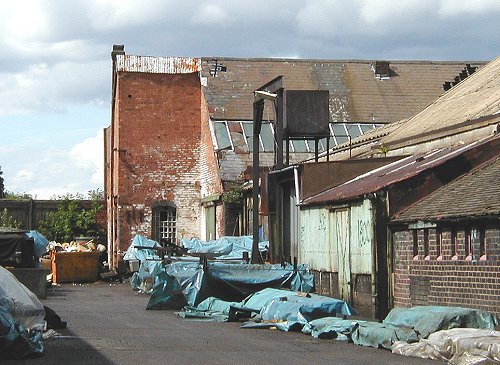

New Griffin Works seen from

Colliery Road. |

In 1928, Theo Waine and his

brother Mr. G. A.Waine, took over the Wearwell Cycle

Company Limited from the liquidators of the Wulfruna

Engineering Company Limited.

Their sons, H. V. Waine and T.

A. Waine were issued with one ordinary share each,

and appointed as directors at the first shareholders

meeting, which took place at the New Griffin Works.

The new company was registered as the Wearwell Cycle

Company (1928) Limited. |

| Initial finance was provided by

the issue of £4,000 worth of £100, 7% debentures

which were the responsibility of H. V. Waine, who

had also been appointed company secretary. At a

second meeting shortly afterwards it was resolved to

purchase from the Vulcan Manufacturing Company

(Wolverhampton) Limited, the plant, tools and

stock-in-trade of the cycle manufacturing side of

their business, for £10,209.16s.5d. |

| A view of the southern end

of the works taken in 2001. |

|

|

The eastern end of the

buildings in the previous photograph, also from

2001. |

| The back of the building

that fronts onto the canal.

From a photograph taken in

2001.

|

|

|

A close-up of the rear

building. Also from 2001. |

A full range of cycles were on

offer in 1929 including tradesmen's cycles,

juveniles, scooters, and sports machines.

The Vulcan

Manufacturing Company (Wolverhampton) Limited applied for

6,000 ordinary shares of £l each to be issued for

cash, and in 1931 the factory was expanded to

include the production of 'Wolf' motorcycles.

The company prospered and sales

continued to increase.

The works were badly damaged

by fire in March 1932 when fire fighters battled for

eight hours to control the fire, which caused

£10,000 worth of damage. |

| Mr. H. V. Waine, a keen

motorcyclist, was responsible for the design and

production of both motor cycles and cycles, while

Mr. T. A. Waine was responsible for sales. In July

1932, Mr. G. A.Waine, and Mr. J. V. Waine of the

Vulcan Manufacturing Company, were each issued with one

share each, and appointed advisors to the company.

|

| |

A Wearwell Gents Popular

bicycle. |

|

A Wearwell Ladies Popular

bicycle. |

|

| |

A childrens tricycle. |

|

Waine Eastern Agencies of

Singapore, were appointed sole selling agents for

India, Ceylon, Burma, Straits Settlements, Siam and

China. Other agents elsewhere were subsequently

appointed. A considerable number of cycles were

exported to India, and post war Wearwell (India)

Ltd, a wholly Indian owned company, manufactured

cycles with technical support from the Wolverhampton

company, which had reverted to the title of the

Wearwell Cycle Company Limited in 1933. Motor cycle

production finally ended during the war.

|

|

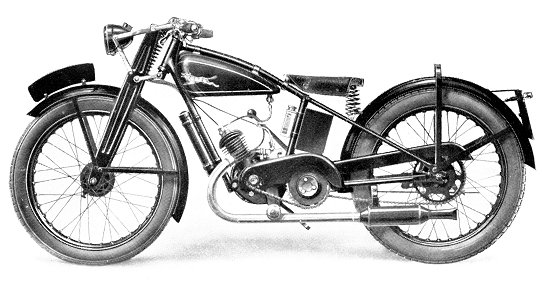

A Wolf 'Cub' from 1932. |

|

| |

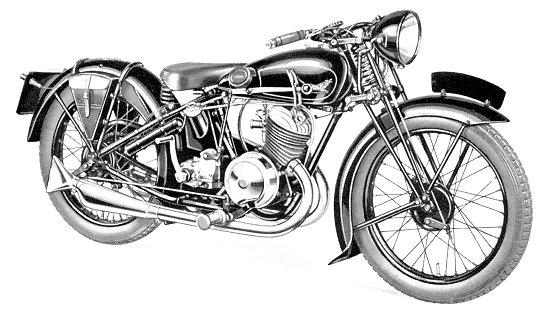

A Wolf 'Super Sports' from

1937. |

|

H. V. Waine, who was an air

raid warden during the war, remarked one night

during the blitz that there was quite a blaze on the

horizon, only to discover it was his own factory!

The workers set-to the following day and soon had

some production restored. The factory buildings were

quickly rebuilt, though fire damaged machinery was

not all cleared away until after the end of the war.

After the war the cycle side of

the business continued to be successful with 75% of

sales going abroad, and the company cycle team won

the Tour of Britain cycle race in 1953. By this time

the company employed several hundred workers, and

also developed a toy department making children’s

tricycles, swings and other items.

Unfortunately sales declined in

the late 1960s. As a result the Vulcan

Manufacturing company went into voluntary

liquidation in 1969, and the goodwill was sold to Tippers,

who were in the same line of business.

Today (2020), New Griffin Works are

derelict. The factory was occupied by hydraulic equipment manufacturer Hydrafit,

but its future is now uncertain. The part of the factory where the bicycles

and motorcycles were built has gone.

The factory in 2001 when it

was occupied by Hydrafit. |

|

Return to the Canals

and Industry Menu |

|