|

|

| Local

Industries

The

Goodyear Tyre & Rubber Company (Great Britain)

Limited,

The Goodyear Tyre and

Rubber Company (Great Britain) Limited is

intimately associated with the vast Goodyear

organisation, the world's largest rubber

manufacturers, whose operations extend to the

four corners of the earth.

Goodyear commenced business

in Great Britain in 1913, and steadily built up

a very sound, extensive business in rubber

products, particularly tyres and tubes. The

consistently good service of Goodyear products

combined with a straightforward dealer

programme, was naturally chiefly responsible for

their sustained progress.

In 1927 it was decided to

provide increased production facilities to cope

with the increasing demand for Goodyear

products, and the factory premises and land now

occupied by the company at Wolverhampton

extending over 70 acres were acquired. The

present plant has an output capacity of over

800,000 tyres and 800,000 tubes per annum, and

is so laid out as to permit such expansion as

the increasing business may render necessary. |

|

At the time of writing,

a total number of 1,300 men and girls are

employed, the factory working 24 hours a day

in three 8 hour shifts.

The factory is chiefly

engaged in the manufacture of pneumatic

tyres and tubes for motor cars and

motorcycles, and giant pneumatic tyres and

tubes for both passenger and goods transport

vehicles.

In this connection it

is worthy of note that Goodyear introduced

and pioneered the giant pneumatic tyre in

Great Britain, which type of tyre has played

such an outstanding part in the development

and progress of passenger transportation by

bus and coach in this country.

The ideal of Goodyear

quality is kept prominently before the

attention of all employees by means of

printed notices "Protect our Good Name"

posted in all the shops and offices

throughout the Goodyear plant.

Social and sports

activities and other forms of welfare work

are recognised as being particularly

conducive to the maintenance of friendly

relations and co-operation between all

sections of employees and the management,

and these activities are consequently given

every possible encouragement. |

|

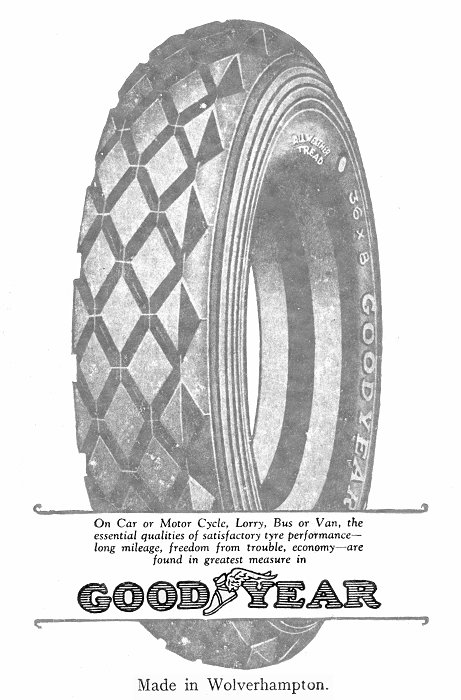

Guy Motors Limited,

Fallings Park, Wolverhampton

With a factory equipped

with the latest and best that scientific

works management can provide, covering 12

acres and employing 1,200 men, producing a

range of commercial motor vehicles meeting

practically every road transport need, from

25cwt. light express delivery vans and 20

seater buses and coaches to 7 ton

six-wheeled goods vehicles and 72 seater

six-wheeled double deck buses, the

well-known Fallings Park firm of Guy Motors

Limited has grown to its present size and

importance from quite small beginnings.

In March, 1915, a start

was made at Fallings Park with a factory

covering approximately half an acre

employing about fifty men, producing one

model only, a 30/40 cwt. commercial motor

vehicle chassis. Towards the end of 1916 the

factory came under the control of the

Ministry of Munitions, and commenced the

manufacture of engines for tanks and lorries

for the Government, and at the end of 1917

the output was fifty per week. Depth charges

to cope with the submarine menace were also

manufactured, the output being two hundred

per week. In 1917 the company built a small

number of experimental aeroplane engines of

the "wasp" type. In the following year they

built the first experimental "dragon fly"

aero engine in a world record time of twenty

four days. As a result the Government placed

a large contract with the company for aero

engines, which were in course of production

when the armistice came. 1919 saw the

reorganisation of the factory to a peace

time basis for the manufacture of commercial

motor vehicles.

We will pass over the terrible slump

period which succeeded the hectic and

artificial boom following the armistice, by

saying that the company, like all the other

British commercial motor vehicle

manufacturers, had a very hard time, with a

market flooded with re-conditioned war-worn

vehicles, and it was only the ingenuity and

resource of a capable management that

enabled the company to pull through. |

|

Progress and expansion

has since been rapid. About two years ago

the company introduced the rigid six-wheeled

motor vehicle, which like all innovations,

had the usual prejudice to overcome.

That the three-axle

vehicle was sound in principle, giving

safety, smoothness of running and economy on

a scale hitherto impossible with the

conventional four-wheeled method, has been

proved by the large number of GUY

six-wheelers, both goods and passengers, now

to be found in service all over the British

Isles, not to mention the colonies and other

distant parts of the world.

The firm's well-known

slogan "Ten years in advance of the times"

is no idle boast, as they have always been

distinguished for their enterprise in

reaching forth for the best. |

|

|

Cannon Iron Foundries

Limited, Deepfields, Coseley

This well-known firm

has already entered its second century's

existence, having been founded by Mr. Edward

Sheldon in 1826, and it is interesting to

note that the present directorate are direct

descendants of that gentleman.

The well-equipped works

cover an area of twenty acres, and further

extensions are in progress. Situated on

either side of the L.M. and S. Railway,

Birmingham to Wolverhampton line, adjacent

to the Deepfields goods and passenger

stations, and also served by the Birmingham

Canal, there is every facility for the

prompt despatch of goods to any part of the

country. The firm's fleet of motor lorries

enables deliveries over a wide area to be

expeditiously made, and the Birmingham to

Wolverhampton new trunk road runs within a

quarter of a mile of the works.

For several years the

firm has specialised in gas stoves for

cooking and heating, including gas cookers

and grillers, gas fires, gas radiators, gas

washing boilers, gas irons, etc., all so

essential to the up-to-date labour-saving

home.

Their latest high-grade cookers with

enamelled exteriors and interiors meet the

most exacting demands of modern housewives

for efficiency, hygiene, and convenience.

|

|

Special mention

should be made of the Cannon new

inclined gas fires introduced by them a

few years ago. This principle exclusive

to Cannon products gives a considerably

improved distribution of the radiant

heat, and is a noteworthy advance in

modern gas fire construction. The new

inclined fires are supplied in several

distinctive designs and finishes, and

have met with remarkable success

throughout the country.

Their "Belle"

gas-heated radiators are also a

speciality, and are eminently suitable

for heating shops, offices, halls,

corridors, etc., where no flue is

available. Other gas apparatus includes

confectioners' ovens, and cooking ranges

and carving tables for hotels,

institutions, canteens, etc.

Another important

production is chemical plant, i.e., cast

iron vessels of various types, lined

with their hard acid-resisting enamel

for chemical and pharmaceutical

processes. The firm was one of the

pioneers in the cast iron hollow-ware

industry, and Cannon brand is famous

throughout the world for quality and

finish in the tinned, enamelled, and

black sections of the trade.

Other departments

produce cast iron enamelled sanitary

ware, known by their registered trade

mark of "Porceliron," general iron

foundry and colonial castings,

grindstones, mounted and unmounted,

suitable for all purposes, sad irons,

etc. Cannon productions have been

awarded numerous diplomas and medals for

their general excellence and quality. |

|

Bayliss, Jones &

Bayliss Limited, Victoria Works and

Monmoor Iron Works, Wolverhampton

This business was

established in the year 1826. Today the

Victoria and Monmore Works, divided only

by a main road, cover an area of upwards

of 30 acres, and employ some 1,400 to

1,500 workpeople. |

|

The Victoria Works

comprise three main sections:

1 - bolt and

nut and drop stampings department,

manufacturing railway and tramway

permanent way fastenings and telegraph

ironwork of every description. Fencing

and gate department for the manufacture

of iron and steel plain and ornamental unclimbable railing and gates,

corrugated pale and sheet iron fencing,

wire fencing material, tree guards,

etc., hammered art metal entrance gates,

balustrading, balconies, etc., to suit

any style of architecture, and for

municipal buildings, country residences,

public and private parks, and other

purposes.

2 - Foundry, with

up-to-date and thorough equipment,

including chemical laboratory, for the

production of high-class chilled rolls

for the tin and heavy plate rolling

mills, and of grooved grain rolls for

mills rolling light and heavy bars and

sections, general engineering castings,

and those for the company's own

requirements.

3 -The Monmoor

Ironworks comprise puddling furnaces and

forges, two rolling mills thoroughly

equipped with the latest labour saving

plant for economic production. The mills

roll flats, rounds, squares, tees,

angles, channels, H and other sections,

for the trade in general, and for the

use of the bolt and nut and fencing

departments of the company. |

|

|

Manley & Company (Wolverhampton)

Limited, Phoenix Works, Green Lane,

Wolverhampton

This Firm

specialise in the manufacture of

superfine hot and cold lacquers for use

in the electrical, art metal, bedstead

and brass foundry trades, their products

being used in all parts of the world.

Their lacquers were recently used

exclusively on the fittings of several

of the largest Atlantic liners, Great

Indian Peninsular Railways train deluxe,

etc. Messrs. Manley & Company

(Wolverhampton) Limited manufacture

lacquers for all climates.

Other specialities

of this firm are the manufacture of

high-class spirit varnishes for every

trade, French polishes and all

preparations for the cabinet and wood

turnery trade. They are also sole

manufacturers of the powerful germicidal

"Manconaft" antiseptic dust allaying oil

for school and other floors, as supplied

to the leading education authorities,

government departments at home and

abroad for the effective allaying of

dust on wood floors. |

|

Davies brothers

& Company Limited, Crown Works,

Wolverhampton

Davies Brothers

& Company Limited established in

1838, are manufacturers of all kinds

of galvanized goods, such as

galvanized corrugated sheets,

galvanized tanks for storage of

water and other liquids,

also cisterns and circulating

cylinders for domestic hot water

supply; constructional steelwork and

steel framed buildings covered with

galvanized corrugated sheets;

galvanized hollow ware, comprising

buckets and tubs; sanitary vessels

of all kinds; agricultural feeding

appliances, etc.

The firm is

engaged mainly on home trade,

including important contracts with

the War Office and Admiralty.

Travellers make

periodical calls on customers in

England and Wales.

|

|

The British

Oxygen Company Limited, Shrubbery

Works, Lower Walsall Street

The

Wolverhampton works of the British

Oxygen Company, Limited in Lower

Walsall Street, have considerably

extended in the last few years,

their facilities for the production

and distribution of oxygen and

hydrogen gases in cylinders. The

company also manufactures all

apparatus for the use of these

gases, including welding and cutting

blow pipes, regulators, cutting

machines, acetylene plants, etc. |

|

Thompson

Brothers (Bilston) Limited

Bradley

Engineering and Tank Works, Bilston,

which covers an area of ten acres,

was founded in the year 1810, and is

the oldest works of its kind in the

district. For the past fifty years

the business has been carried on

under the directorship of Thompson

Bros. The present directors are

Messrs. F. S., J. A., and H. J.

Thompson, and in the year 1906 the

business was incorporated in a

private limited company, with head

office at the above address.

The Company's

London Office is at Aldwych House,

W.C. 2 : also, they have agents in

Canada, Australia, France, Belgium,

Italy and Romania.

For the last

forty years they have specialised in

galvanizing and annealing plant, and

have supplied these plants to the

British and foreign admiralties,

India Office, Crown Agents for the

Colonies, and the leading

galvanizers in Great Britain and

Ireland, and the manufacturing

centres in all parts of the world.

The method of manufacturing

galvanizing baths by welding,

instead of riveting, was first

introduced and practised by this

firm. Welded galvanizing baths

rapidly superseded the riveted

type. The baths vary in weight from

half a ton up to twenty-three tons,

the latter being the largest

galvanizing bath made in this

country. Complete automatic

machinery for the Production of

galvanized roofing sheets is also

manufactured. This machinery, along

with the galvanizing, is installed,

work commenced, and left in running

order to the entire satisfaction of

the purchaser by their own staff.

Other machinery allied to this

particular branch of industry

include corrugating, curving and

stretching machines, all of which

are actually built at the Bradley

works.

Annealing Pots

used in the preparation of the black

sheets for galvanizing and tinplate

works, also by engineers for

ordinary annealing and case

hardening, form another important

section of their specialities.

Welded steel

tanks for the storage and transport

of petrol. During recent years the

portion of the Bradley works devoted

to the manufacture of these storage

and road tanks has become

increasingly important, and very

rapid developments have taken place

to cater for the growing demands of

the petrol industry and today

Thompson Brothers (Bilston) Limited

are the largest makers in the

country of all sizes and classes of

petrol tanks, both for storage and

road vehicles; the latter being

fitted up complete, including coach

work, painting etc. ready for use.

Transport tanks are also made for

milk, beer. margarine, lubricating

oils, acids, etc. A recent contract

carried out was for petrol storage

tanks and equipment for the Middle

East air route for all the refuelling

stations from Cairo to Karachi, for

Messrs. Imperial Airways Limited. |

|

Welded steel

plate work of large and varied

kinds, for the electrical and

chemical trades, are made in large

numbers. A recent example of the

former were four large turbine

casings for the Clyde Valley Hydro

Electric Scheme, being the first of

their kind in welded steel. For the

latter stainless steel tanks, pans,

mixers, tube work, etc., form a large

part.

Petrol pumps,

for kerbside and garage use of a

patent design, were started to be

made about five years ago, and now

form a large and important branch of

the firm's production, special

equipment for their manufacture and

testing having been installed.

Aircraft metal

work department is actively

engaged on important contracts for

this class of work, including

exhaust manifolds in special

heat-resisting metal for air-cooled

radial engines for use on war and

commercial aeroplanes; also

manifolds for the large British

airship now under construction,

tubular components, pressed and

welded work.

Steel plate

pressings. The works are equipped

with several large hydraulic presses

capable of forming and pressing

steel up to two inches thick. |

|

|

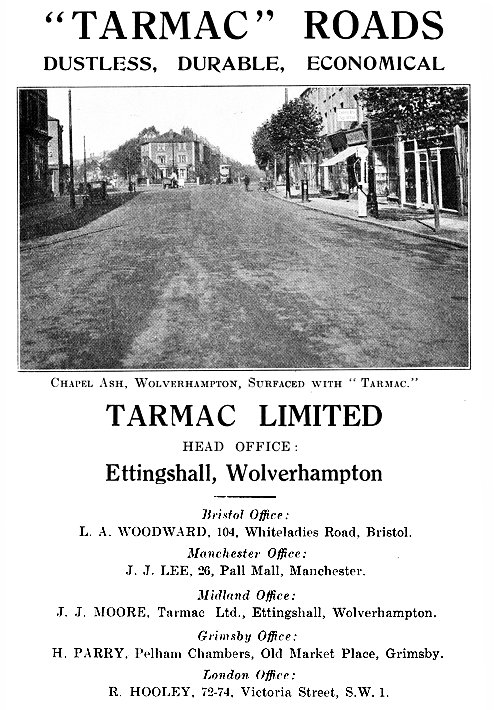

Tarmac Limited

Tarmac

Limited, sole manufacturers and

patentees of Tarmac,

Ettingshall, Wolverhampton.

Tarmac is

the proprietary name of a

material for tar-bound road

construction, manufactured by

Tarmac Limited, Ettingshall,

Wolverhampton, and at twenty

works in various parts of the

country.

The Company is operating

works in Staffordshire,

Northants, Flintshire,

Glamorganshire Denbighshire,

Worcestershire, Derbyshire,

Lincolnshire, North Yorkshire

and Durham. |

|

Tarmac is

manufactured of selected blast

furnace slag, which under the

company's process, is thoroughly

mixed and impregnated with a special

tar compound made by the company to

conform to specific standards.

The selected

blast furnace slag in bulk is broken

by crushing machinery into suitable

sizes for road material, ranging

from 2½ in. down to ⅛ in.

The peculiar

qualities of blast furnace slag make

it a most suitable aggregate for the

manufacture of tarred road material,

and it is claimed that blast furnace

slag is much more effective for this

class of material than natural rocks

or stones. Every particle of

moisture is eliminated from the slag

before treatment by the company.

Tarmac is

delivered from the company's works

by road and rail ready for

application to the road surface.

The material is

extensively used in all parts of

England and Wales, and the company's

annual production represents a very

considerable proportion of the

tarred road material used in this

country. |

|

Tarmac

Limited, Vinculum Department,

sole Manufacturer of Vinculum

concrete, Ettingshall,

Wolverhampton

Vinculum

concrete is manufactured from

selected blast furnace slag and

British Portland cement. It is

produced as precast concrete

units in an immense variety of

shapes and for practically all

industries requiring this

material. These products are

supplied to public works and

road contractors, and this

industry absorbs large

quantities of road kerbs, fence

posts, channel blocks, and

similar material.

Building blocks,

architectural concrete,

manufactured stone, steps,

slabs, sills, etc., are produced

for the building and

constructional engineering

industries, and these products

are distributed over a very wide

area. |

|

Large

quantities of Vinculum concrete

units specially prepared for the

building trades have been used

on housing schemes in various

parts of the country, and range

from simple concrete steps and

shelves to complete concrete

houses including foundations,

walling, roofing tiles, window

frames, and so on.

Pre-cast

units for the electrical

engineer include protection

slabs for high tension cables,

joint coffins, indicator posts,

and cable posts; hundreds of

miles of Vinculum concrete cable

covers have been used in

connection with the high tension

distribution schemes in various

parts of the country.

Other units

include water and feeding

troughs, mangers, farm and

estate fittings, and posts for

all purposes.

Garden

ornaments in great variety are

also made and are very popular.

The Head

Office of the department is at

Ettingshall, Wolverhampton, and

the products are produced at

six, works, the geographical

position of which enables prompt

delivery of these products to be

made with a minimum cost for

transport. Very large stocks of

road kerbs, fence posts, cable

covers, building blocks, door

hoods, and similar units are

carried in order to ensure

delivery of sound matured

material, and a wide variety of

special units are always in

course of manufacture in rapid

hardening cement for prompt

delivery. |

|

|

Joseph

Sankey & Sons, Limited

This firm

was affiliated to John Lysaght,

Limited, when the latter

amalgamated with Guest, Keen & Nettlefolds, Limited, in 1920.

The chief

products of the Albert Street

works are brass and copper

goods; embossed tin and black

plates; copper lifebuoys; pure

nickel hollow-ware for domestic

purposes; wrought steel

hollow-ware (enamelled and

tinned); gas and electric light

shades; general deep pressings

and stampings for the

engineering and motor trades;

aeroplane parts in steel,

aluminium and alloys; domestic

hollow-ware in rust-less iron.

The

Bankfield Works, covering four

acres, are situated half a mile

from Albert Street Works, on the

Birmingham and Wolverhampton

canal, and with direct siding

access to the Great Western

Railway.

The Manor

Rolling Mills are situated at

Ettingshall, near Wolverhampton,

in close proximity to

Ettingshall Road Station, on the LMS Railway, and on the

Birmingham to Wolverhampton

canal. |

|

The main

productions are steel sheets for

the electrical trades, chiefly

the well-known ‘Lohys’, ‘special

Lohys’ and ‘medium resistance’

brands of electrical sheers, and

the ‘Stalloy’ brand of patent

high resistance steel sheets,

steel sheets for deep stampings

and kindred purposes are also

produced here.

The

products comprise Sankey patent

steel wheels for motor cars;

wheels of all types, artillery

or disc, with fixed or

detachable tyre beads or

flanges, suitable for all types

of tyres - beaded, straight

sided and low pressure; complete

sets of wheels for Ford cars,

and one-ton trucks; heavy steel

wheels for commercial vehicles,

with rims to take giant

pneumatic, cushion and solid

tyres, and for railway, trolley

and tram wheels; chassis frames;

axle cases; brake drums, and all

plate pressings for the motor

trade; wings; mudguards and

steel panels and sheet pressings

for motor body construction;

pressings of all types in plate

and sheet, including foundry

ladles, steel barrow bodies and

steel barrels; window, door,

pillar, and other pressings and

steel "key" flooring for tramway

car and railway coach

construction; steel furniture

for office and domestic use,

comprising lockers, bins,

shelving, filing cabinets and

transfer cases; finished bodies

for motor cars, charabancs and

commercial vehicles.

The company

supplied His Majesty's Forces

with four and a half millions of

shrapnel-proof helmets during

the period of the Great War. |

|

Adolphe Crosbie

& Company Limited, Walsall Street,

Wolverhampton

Prominent among

Wolverhampton firms stands the name of

Messrs, Adolphe Crosbie & Company, of

Wolverhampton, which has been making marine

paints and compositions for many years,

which by sheer merit, have gained a

world-wide reputation. All of this firm's

products are marketed under the brand name

of Wulfruna, and the entire range covers

practically every type of paint or

protective material in use, so that

obviously, mention can only be made here of

a few outstanding items.

In catering for the

shipping industry, Messrs. Adolphe Crosbie

and Company produce anti-corrosive

composition, anti-fouling composition,

boot-topping, and odourless white enamel for

holds, etc., finest white and coloured

enamels for cabins, etc., and all classes of

varnishes and oxide paints for ship's use.

The anti-corrosive

composition is a first-class material for

preventing corrosion; it dries quickly, and

it can be supplied in three colours - dark

red, chocolate and purple brown, and is used

by many of the leading shipping companies.

The problem of boiler

incrustation is one that has to be dealt

with in almost every branch of industry, and

for this reason Messrs, Crosbie produce a

highly efficient boiler composition, which

is so successful in the prevention of scale

and incrustation that it is recommended by

boiler insurance companies, engineers of

high standing, water companies, and steam

users in every branch of trade, while

Messrs. Adolphe Crosbie & Company have a

list of upwards of three thousand firms in

all trades who are constant users of this

composition.

Other manufactures of

this Company include Crosbie's pure quality

ready mixed paints, which are guaranteed to

be manufactured from pure pigment, genuine

linseed oil, and the correct proportions of

driers and turps. These paints have an

exceptional covering capacity, a super-durable

glossy finish, and are specially prepared to

withstand the strain of severe climatic

conditions; at the same time, they are most

suitable for inside decorations. |

|

Mander

Brothers Limited, varnish and paint

manufacturers, Wolverhampton

Brief Survey covering

one hundred and thirty seven years –

1792-1929.

The firm of Mander

Brothers, Limited., printing ink, colour and

varnish manufacturers, Wolverhampton was

founded in 1792 by Benjamin Mander, who was

the great-great-grandfather of the four

present junior directors and

great-grandfather of Sir Charles Mander,

Bart., the head of the firm. The business,

originally that of Japanner and tin plate

worker, and since 1803 as varnish maker, is

carried on at the same spot, though on a

greatly extended scale, as 137 years ago,

and during all that period the partners and

directors have always been Manders and

direct descendants of the founder. Probably

few other firms can show a similar record of

continuity, and as the four juniors have

each one son, the succession is likely to be

maintained.

In addition to the St.

John Street Works, where printing ink,

varnish, paint and enamels are made, there

are the Townwell Works nearby, engaged in

the production of dry colours. At a distance

of about 2½ miles are the Wednesfield Works,

conveniently situated on the canal and

railway, where the manufacture of printing

ink is carried on. Large new works are now

being developed at Heath Town, where a tin

can making factory and a paint and enamel

works have been laid out on the most

up-to-date lines, and are now in operation.

From small beginnings,

the firm has obtained a leading position in

every part of the world for its well-known

products. As the business grew and

developed, it became increasingly difficult

to maintain the personal relationship

between employer and employee which had been

traditional; and with a view to

re-establishing this, a welfare scheme was

started in 1920, which has made remarkable

and rapid progress, showing the wealth of

goodwill which is available where human

beings are associated together in business,

if proper steps are taken to evolve it.

The welfare executive

committee consists of the directors and

twelve representatives from the various

departments, with five co-opted members, and

deals with many different aspects of

entertainment, recreation and education. |

|

There are in all twenty

sub-committees covering the following

subjects - finance, journal, bowling,

entertainments, bagatelle, holiday fund,

chess, gardening, cricket, tennis, football,

canteen, hockey, coal club, library,

dramatic, swimming, dressmaking, catering

and saving certificates.

There is a recreation

ground covering over five acres, comprising

at present, football, hockey and cricket

grounds, two bowling greens, two hard and

two grass tennis courts and a pavilion,

where whist drives, dances and concerts are

held. There is also a canteen in a separate

building.

In all cases the

capital charges of playing fields, etc. are

borne by the firm, and the maintenance and

running expenses are borne by the employees

through weekly contributions and profits

from various entertainments.

There is also in

operation a contributory pensions scheme.

Each workman contributes one shilling a

week, and on reaching the age of 65 becomes

entitled to a pension of 35/- a week for

life.

Besides this, £10,000

of preference shares have been set on one

side for the workpeople, and the holders of

these shares are entitled to a fixed

dividend of 7% and a proportion of the

profits. |

|

|

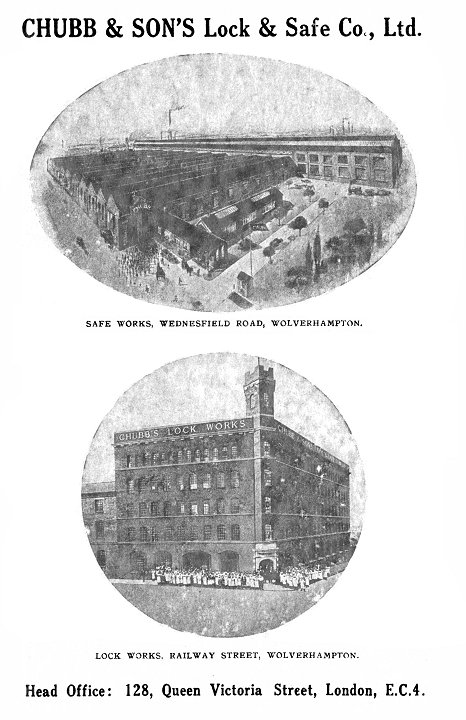

Chubb & Son's Lock &

Safe Company Limited, Railway Street,

Wolverhampton

Also Wednesfield Road,

Wolverhampton and 128, Queen Victoria

Street, London, E.C.4

Jeremiah Chubb patented

his first lock, known as the Chubb Detector

Lock, on February 3rd, 1818. Subsequent

improvements were devised and patented in

1824 by Charles, brother of the original

inventor, and, with certain modifications,

the principle introduced by Charles Chubb

survives today. The number of patents

granted to Chubbs since 1824 is very large,

many of the improvements being of

considerable technical interest.

The first Chubb locks

were made in a small workshop in Portsea,

Hampshire, but their manufacture was quickly

transferred to the great lock making centre

of Wolverhampton. Charles Chubb soon

disposed of his hardware business at Portsea,

and moved to 57, St. Paul's Churchyard,

London, E.C. confining his trade there to

the selling of his patent locks. |

|

Safes, strong rooms,

and safe deposits were subsequently added,

and since the removal to 128, Queen Victoria

Street, London, in 1877, this latter branch

of the business has grown to large

dimensions.

In 1908, Chubb's Safe

Works situated in the south of London were

sold, as at that time the desirability of

concentrating all manufacturing operations

under central control became increasingly

apparent, and in addition to extensions for

safe making being provided at the large

Wolverhampton Lock Works, new and extensive

buildings for the manufacture of safes,

strong room doors, treasuries, strong rooms

and safe deposits, were erected on a

ten-acre site at Wednesfield Road, near the

lock works.

Various considerations

influenced the concentration of Chubb's

works at Wolverhampton. In addition to being

a great centre of the hardware and metal

trades, it offered better and healthier

housing facilities for the workers, while

rents and rates were considerably lower than

in London, a fact which weighed favourably

with both employers and employed.

The wisdom of making

Wolverhampton the manufacturing headquarters

of the company has since been amply proved,

whilst the products of The House of Chubb

have become famous throughout the world. |

|

|

|

|

Return to

public buildings |

Return to

the beginning |

Proceed to

Advertisements |

|