| F. H. Lloyd & Company

Limited - The early 1930s |

| This section consists of photos of some of the

many products that were made at the steel works in

the early 1930s, along with views inside the

factory. The company always strived for uniformity

in its products, thanks to the up-to-date plant, the

specialists who worked on each stage of production

and two generations of people with continuous

experience in the production of steel castings of

the highest order. At this time, the company had

produced around a quarter of a million steel

castings since production began. |

|

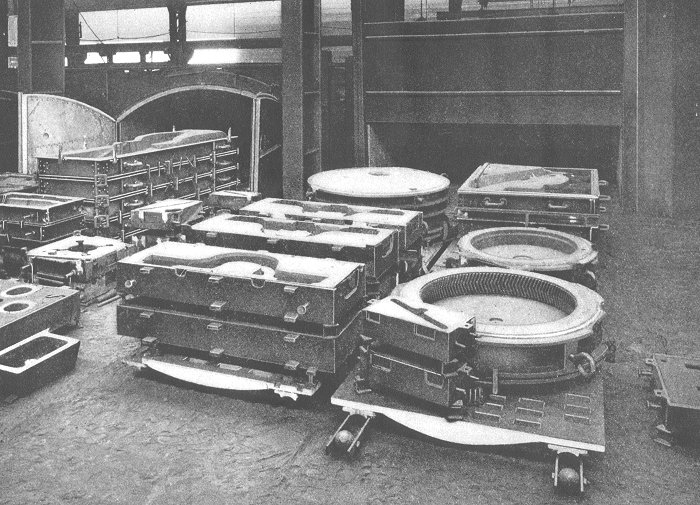

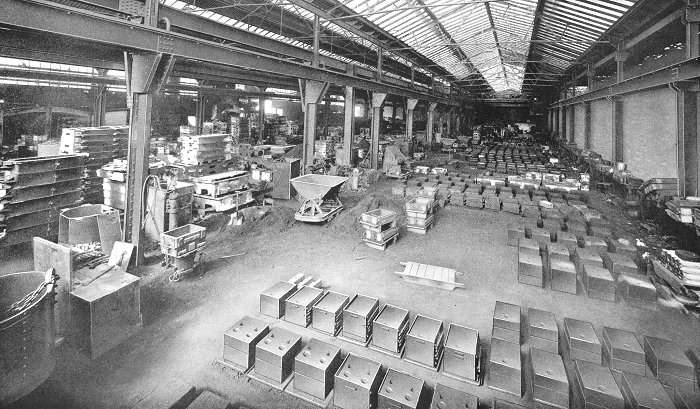

Moulds in the heavy foundry

section that have just emerged from the drying stoves,

prior to casting. |

|

One of the casting bays in the

heavy foundry. |

|

Coring-up moulds in the heavy

foundry. |

|

Wheel centre moulds in the heavy

foundry, ready for casting. |

|

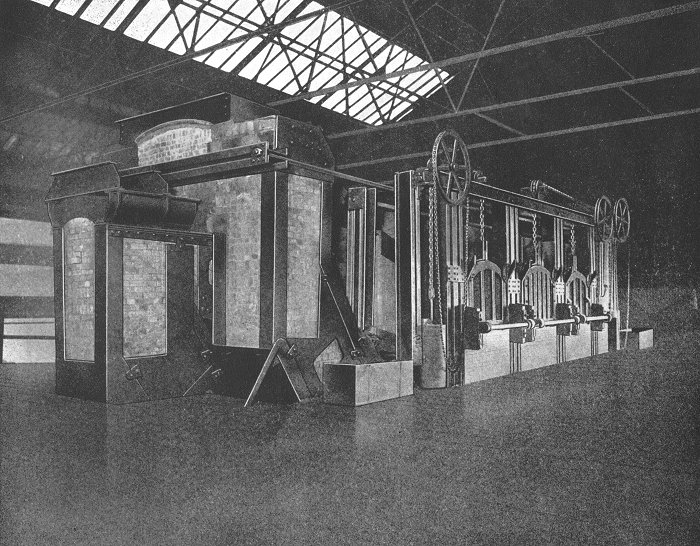

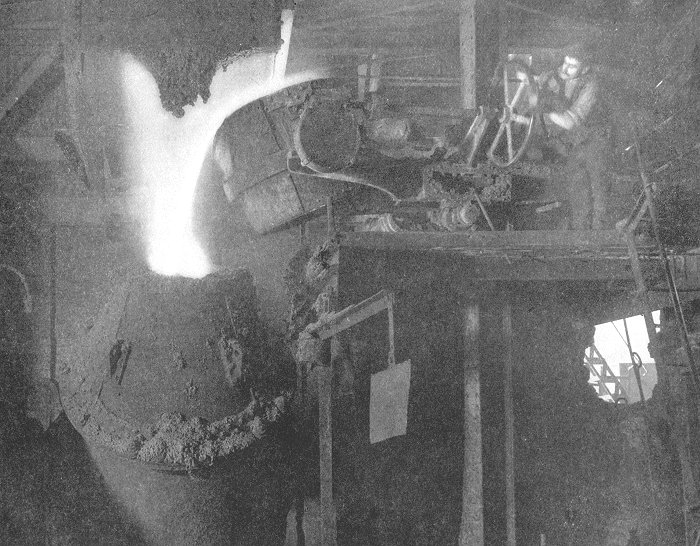

One of the 20 ton open hearth

furnaces in the heavy foundry. |

|

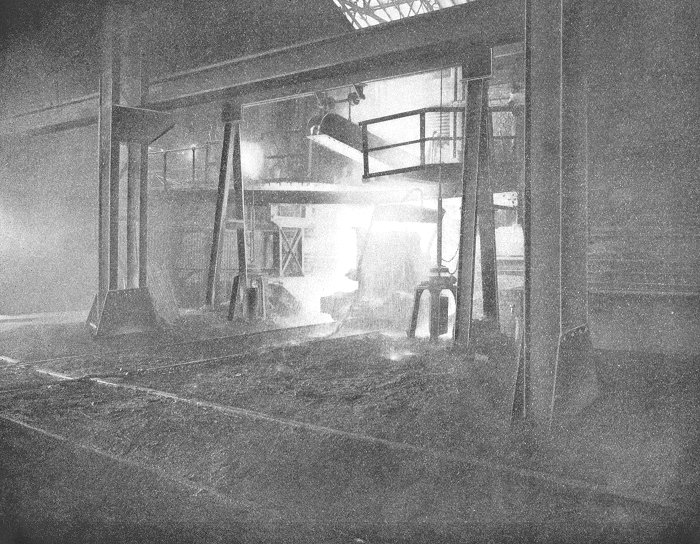

Filling a ladle from a furnace in

the heavy foundry. |

|

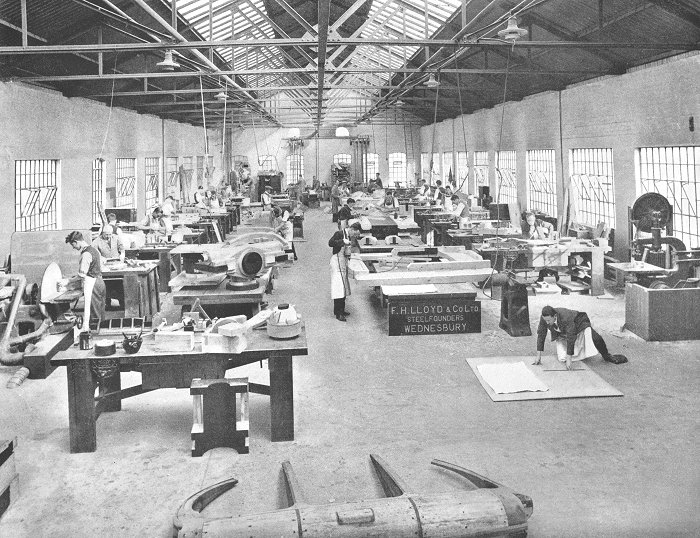

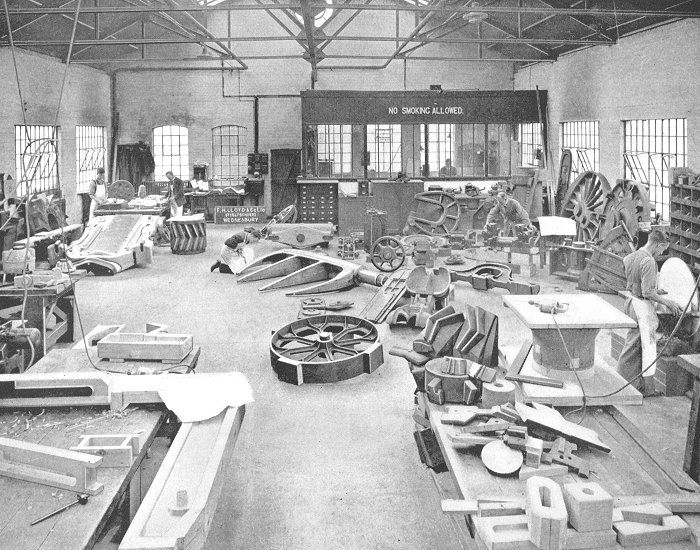

The pattern Shop. |

|

Patterns in the pattern shop, laid

out ready for checking. |

|

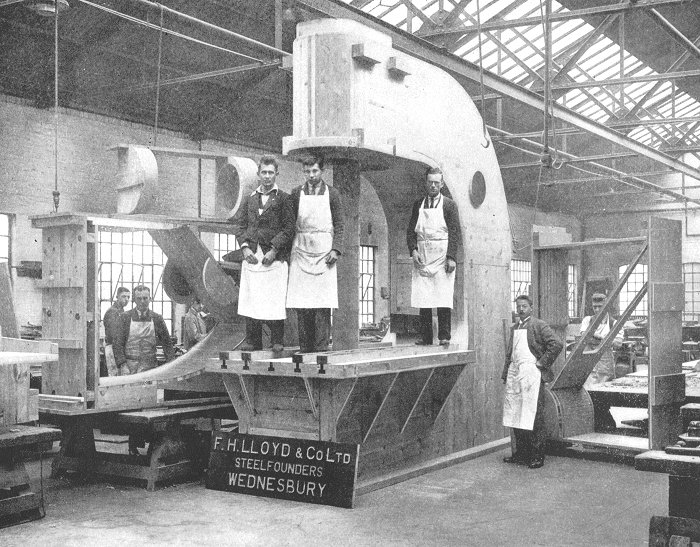

A large pattern being made ready

for the foundry. |

|

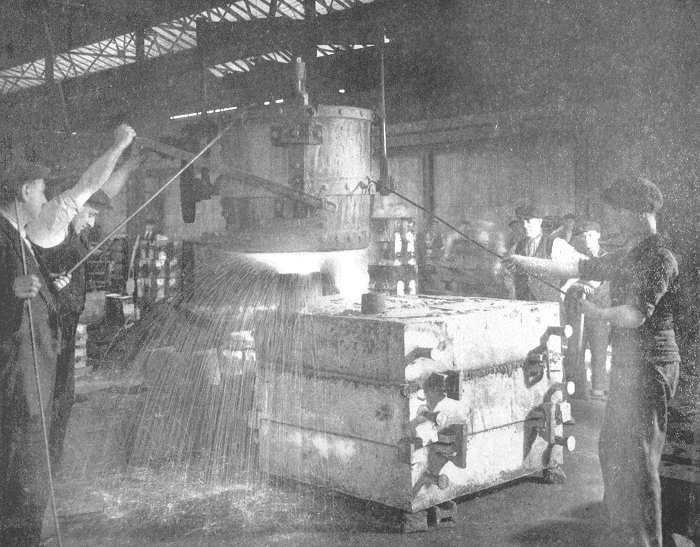

Steel being poured in the light

foundry. |

|

The light foundry. |

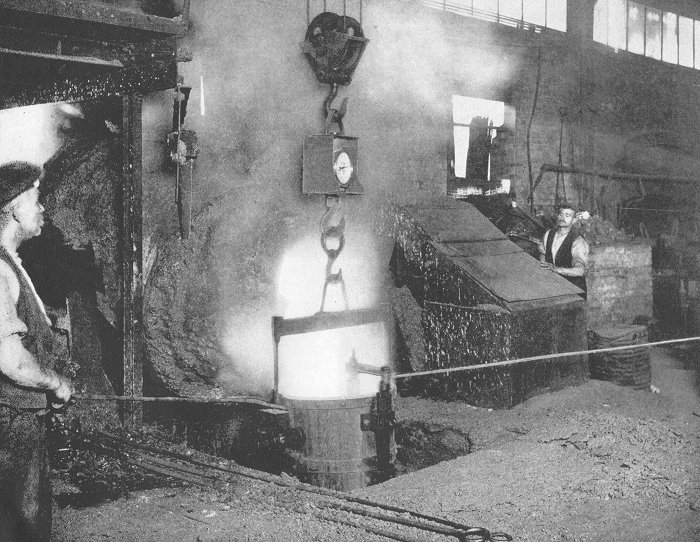

Molten iron running from a

cupola furnace into an intermediate ladle for the

desulphurisation process, in the light foundry. |

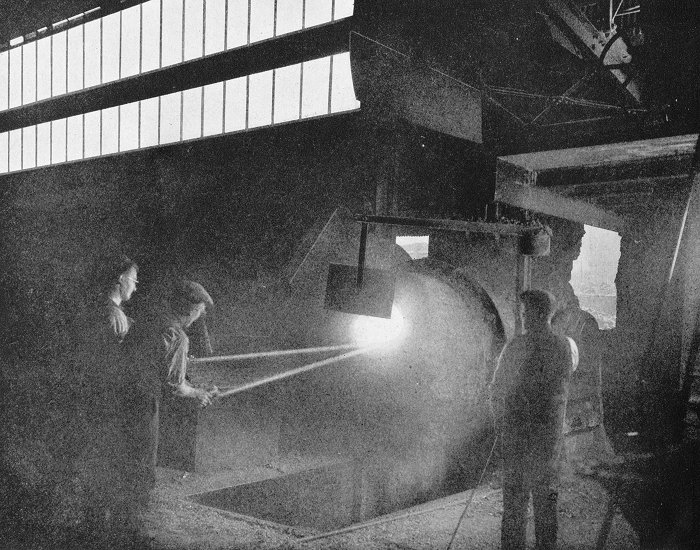

Pouring molten iron into a

converter where it will be subject to a blast of air to

oxidise any remaining manganese, silicon or carbon. |

|

Stirring the molten metal and the

recently added alloying elements in a furnace in the

light foundry. |

|

Pouring steel into a teeming ladle

in the light foundry. |

|

Casting in the light foundry. |

|

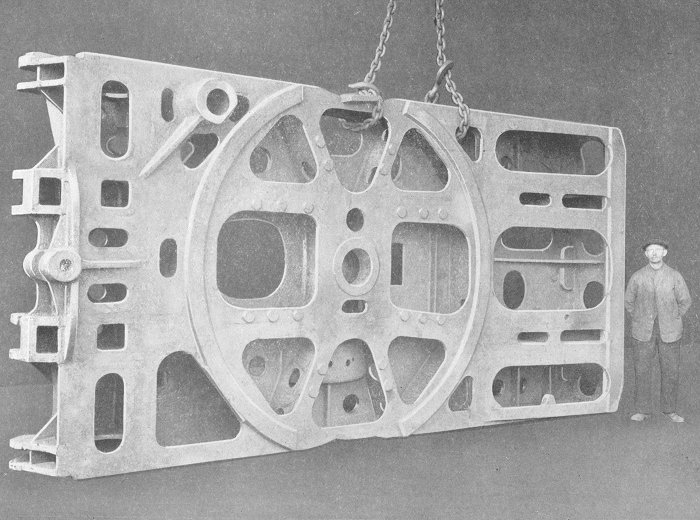

A bed plate casting for a

Ruston-Bucyrus excavator after final machining. |

|

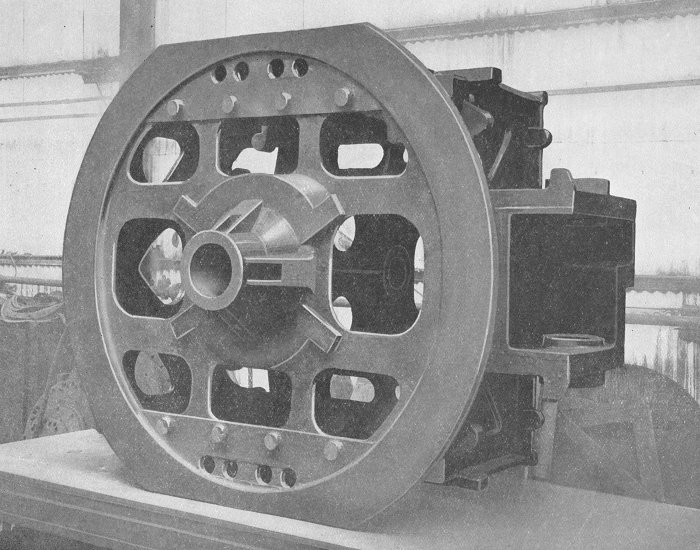

Another component for a

Ruston-Bucyrus excavator, also after final machining. |

|