|

Industry

In the late 1950s and early 1960s

Wednesbury was still a successful manufacturing town

with large numbers of factories and diverse industries

of all sizes. A well known local company was Prodorite

Limited, based at Eagle Works in Leabrook Road. The

company produced a range of chemical coatings that were

resistant to corrosion, industrial floor materials, and

acid-proof constructions for tanks, floors, process

vessels, drainage and effluent systems, and fume

extraction.

Another, very different concern was

Geoffrey Hughes Limited, in Mounts Road. They produced

ladies’ and gentlemen’s clothing, mainly made to

measure, and also stock garments. The company

employed around 130 people in an up-to-date factory,

with a canteen, and a social club. Its garments gained a

reputation for quality, skilled workmanship, and good

value for money. |

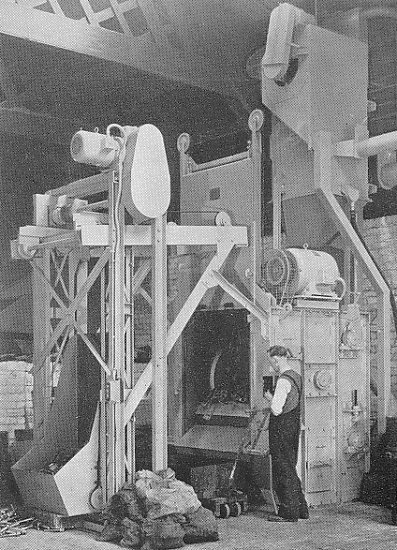

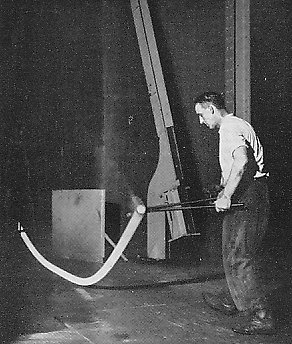

Up-to-date shot blasting equipment

at Frost & Sons (Moxley) Limited. |

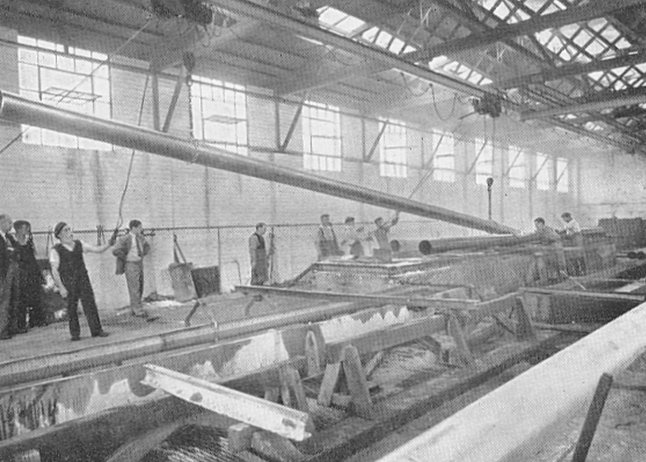

Another local industry was galvanising. Frost & Sons

of Falcon Works, Church Street, Moxley specialised in

galvanising electricity transmission towers for the

Central Electricity Board, and galvanised every kind of

wrought and cast iron work, and tubes and fittings. The

company had a reputation for quick service, high quality

work, and low prices. The firm, which was founded in

1889 as tube and general galvanisers, subsequently

opened another factory at Rough Hills,

Wolverhampton for the galvanising of structural

steelwork, overhead transmission towers, and very long,

heavy sections.

A third factory also opened at Ebro Works, Tividale,

Tipton, which specialised in the centrifugal galvanising

of nuts, bolts, and washers etc.

The business survived until 2002 when it was wound-up

voluntarily, as can be seen in the notice below. |

|

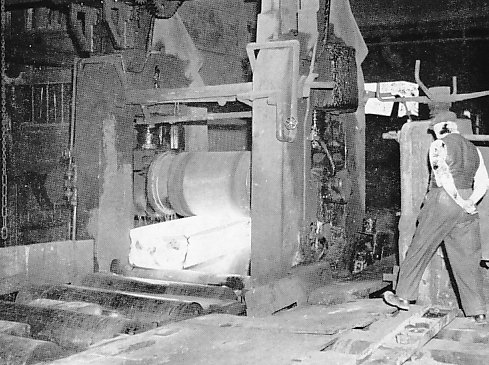

Galvanising tubes, 40 feet long

and 11 inches diameter, in Frosts' factory at Moxley. |

| The winding-up notice that

appeared in the Gazette newspaper. |

|

An advert from 1954.

| Another firm, Roberts & Company (Wednesbury Limited)

of Franchise Street, also specialised in galvanising

work for overhead electrical transmission lines, and

also manufactured signal ladders for the railway, and

iron work for lorry and bus bodies. |

|

The large hot-dip galvanising tank

at Henry Hope & Sons Limited. |

A third galvaniser, Henry Hope & Sons Limited in

Woden Road, manufactured, and hot-dip galvanised the

companies own steel windows, which were made to the

highest standards. The factory contained highly mechanised plant, and

the deepest galvanising bath in the country, which

allowed the firm to galvanise all sizes of products for

other manufacturers, in large quantities, at an

economical cost. |

| For many years Wednesbury was well known for its

iron and steel works.

The Patent Shaft and Axletree Company, based in

Leabrook Road, had a long and successful life, and was

one of the first steelworks in the country to use a

Bessemer converter.

In fact Henry Bessemer conducted many of his early

experiments at the factory. |

Tapping an electric arc furnace at

F. H. Lloyds. |

|

The old Patent Shaft cogging mill. |

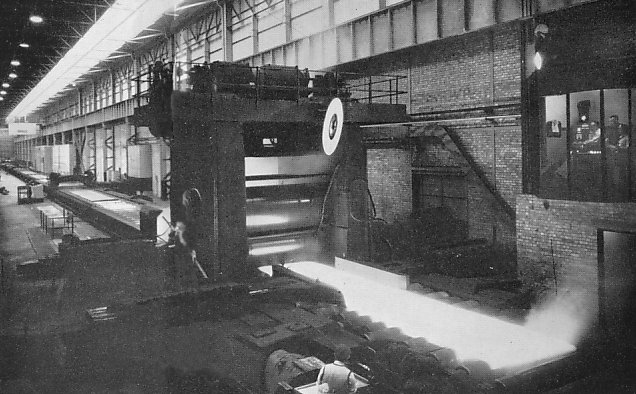

By the late 1950s the company began to concentrate

on its rolling mills, and invested £8m in new plant,

including two 75 ton open hearth furnaces, modernisation

of the melting shop, and raw material handling

facilities, conversion of some of the existing furnaces

to oil firing, a new slabbing and blooming mill, a

rotary hearth-slab reheating furnace, and a new plate

mill.

The project increased the company’s ingot output to

300,000 tons per year, with a vastly superior finish. |

The new plate mill at the Patent Shaft Steel

Works.

|

A long-surviving steel company, F.

H. Lloyd & Company Limited, of James Bridge, was founded

in 1878. It had the largest steel foundry in the

country, and not only produced castings for the home

market, but also for many other parts of the world.

Another old company, John Bagnall &

Sons Limited of Leabrook Iron Works, manufactured wrought

iron, re-rollers of steel strip, bars and sections, and

undertook acid pickling, normalising, and annealing

steel strip and bars. The company’s rolling mills

produced steel strip in the range of 1 inch to 12 inches

wide, and in thicknesses of 14 gauge I.S.W.G. up to 1

inch. Bagnalls also manufactured square edged flats, and

steel tubes and fittings for the vehicle industry, and

splayed barrel hoops for the brewery trade. |

|

The once well known edge tool

manufacturer Edward Elwell Limited, in St. Paul’s Road,

Wood Green manufactured all kinds of high quality tools

for sale at home, and all over the world. In the late

1950s the company had completed a project to modernise

the factory and plant, to produce hand tools which could

not be surpassed anywhere in the world. The firm was

famous for its excellent axes, spades, shovels,

reaphooks, slashers, and choppers, of which it was

justifiably proud.

Wednesbury also had press working

companies including the George Clarke Presswork Company

Limited in Woden Road West. The firm carried out general

presswork, from small hand-pressed items up to power

presswork, with a capacity of 100 tons. Products

included ferrules, electrical pressings, washers,

pressings for the motor industry, springless oil seals,

welded fabrications, and turned parts.

Another important industry was

railway wagons, rolling stock, and locomotives, built at

the Old Park Works in Darlaston Road, by the Metropolitan Cammel Carriage and Wagon Company Limited. The company,

based at Saltley in Birmingham had four factories, and

in the late 1950s was the largest manufacturer of

rolling stock in Europe. |

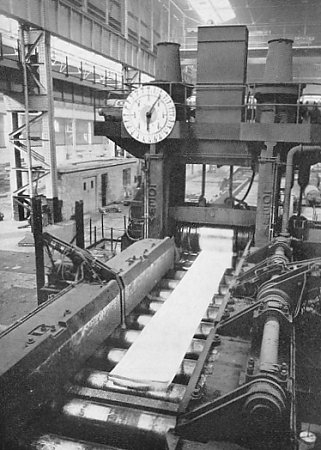

The new blooming and slabbing mill at the Patent Shaft Steel Works. |

| In 1961 Old Park Works produced the mechanical

structures for 35 electric locomotives for South African

Railways, the ‘Prestwin’ twin silo air discharge wagon

for carrying bulk powders, and a salt wagon for the

British Transport Commission. |

|

Extruding seamless pipe at

Prothero Works. |

Wednesbury had two prominent

electrical equipment manufacturers, William Sanders, and

the Power Centre. W. Sanders & Company (Wednesbury)

Limited of Falcon Works in Ridding Lane was enjoying its

last few years of independence. Within 6 years it would

become part of Westinghouse, move to Hungerford, and

soon face closure.

The firm produced all kinds of

switchgear from large installations to small fused

switchboxes, and fuse carriers, and fuses. Sanders’

products were sold at home and abroad, and the Sanders

name was known throughout much of the world. The company

employed around 60 people.

The Power Centre was based in Lloyd

Street, and Elwell Street. It came to Wednesbury in

1908, and later became part of the Electrical Division

of Tube Investments Limited. Its products were

distributed through branches of the Simplex Electric

Company limited, also part of the Tube Investments

group. |

|

The Elwell Street factory opened in

1958 and had the most up-to-date plant for the

manufacture of busbar trunking, and cable trunking.

Other products included electrical distribution

equipment, switchboards, cable boxes, and busbar

systems.

Another, and very different company

was The Hallen Engineering Company Limited in Portway

Road which became well known for its high quality

work. The firm specialised in machining casting, forgings, and the production of

all kinds of turned parts. Customers included the

Admiralty, the Air Ministry, the Ministry of Supply, the

Post Office, British and Foreign Railways, Docks and

Harbour Boards, and the Atomic Energy Commission. |

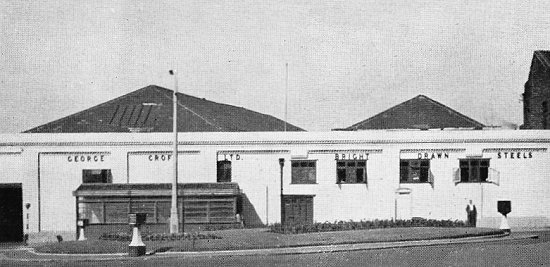

George Croft Limited on the High Bullen.

|

A landmark at the High Bullen, by

the traffic island, was Newbright Steel Works, run by

George Croft Limited, producer of bright drawn steel,

high quality centreless precision turned bars, and

tested steels to War Office, Admiralty, and British Rail

specifications. During the 1950s and 1960s the firm

prospered thanks to customer good will, and high quality

products.

One of the important products,

produced in vast numbers throughout the Black Country

was washers. They were produced in large numbers in

Wednesbury by Charles (Wednesbury) Limited at Bridge

Works in Bilport Lane, off Holyhead Road, near the

bottom of Holloway Bank. The firm produced all kinds of

washers in steel or brass, including bright steel turned

and chamfered washers, plain bright steel washers, and

roofing and engineers black washers. The firm was run by

C. and R. A. Pugh. It was founded in 1930, and still

exists today, employing 110 people. |

|

|

|

Return to

Education |

|

Return to

the contents |

|