|

9. Elisabeth and Modernisation 1951 - 1964

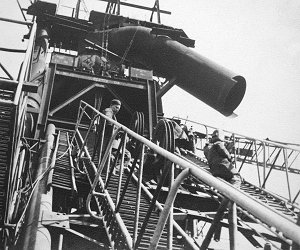

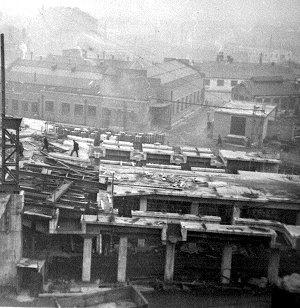

The photos on this page were taken by Tim

Hadley when he was an apprentice with Stewarts and Lloyds from about

1947 onwards. They show the building of the Elisabeth furnace

and associated works.

|

Elisabeth. |

To continue the narrative, we now revert to our anonymous source: "When the decision was taken in 1951 to build a new blast furnace,

the first in the country to be designed from the start to operate on

high‑top pressure, the modernisation of the works as a whole really

began.

Steelmaking capacity was more than trebled with vastly

improved methods of handling and with fixed furnaces capable of as

high rates of output as the quality of steel would permit." |

| I take it that the furnace referred to is the

famous "Elisabeth". Mary Mills and Tracey Williams, in their "Images of England: Bilston, Tettenhall and Wednesfield", say that

it replaced three smaller blast furnaces and was first lit in 1954.

"By tradition, after relining, the furnace had to be relit by a

young girl. The only time it was lit by a man, the furnace went

out". Ron Davies, who worked for E. N. Wright Ltd., the

maintenance company, confirms this tradition and know of several

instances where attempts were made to light the furnace by a man,

all of which failed.

So this furnace was lit by Elisabeth (so spelled, with a s,

not a z), the little daughter of one of the senior managers of the

works. |

Elisabeth in the course of

construction. |

Ron Davies also recollects that, so new and innovative was the

Elisabeth furnace, that it took them two years to get it running at

its best.

|

Elisabeth. |

W. K. V. Gale in his “The Black Country Iron

Industry” (The Iron and Steel Institute, London, 1966) comments on

Elisabeth and the Bilston steel works generally in 1965:

"There is now only one

blast furnace left in the area where once there were 200, but it is

a large modern one and unique in that it was the first

high‑top-pressure furnace to be built, ab initio, in Great

Britain to operate in this way.

This is the Elisabeth furnace,

built in 1954 at the Bilston Steelworks of Stewarts and Lloyds Ltd

(formerly Alfred Hickman Ltd). Of 27 ft hearth diameter, Elisabeth

provides molten iron for the steelworks, which have also been

completely rebuilt."

|

| Gale continues: "The new furnace, incidentally, is far from

being the only pioneer installation at the Bilston Works. Among the

others was the Ward-Leonard-Ilgner set provided by the Electric

Construction Company when the former 36 inch mill was electrified in

1907; this was probably the first in a British steelworks.

Bilston

Steelworks now have two 1000ton inactive mixers, seven open‑hearth

furnaces of 100-120 tons capacity, a 40inch two-high reversing

blooming mill, and a 32 inch two-high reversing bar and billet mill.

A vacuum degassing plant is also installed. The principal products

of Bilston Steelworks are tube-making ingots, billets 22 to 72 inch

square, slabs 5-15 inches wide, and rounds 34 inches in diameter. All the

rolled products can be produced in finished lengths up to 30feet." |

Elisabeth in the course of

construction. |

|

Elisabeth. |

This passage appears in a chapter ominously

entitled "Epilogue" but which does open with the words:

"It seems

that cast iron will continue to be made in the Black Country for

some time". And that was written in 1966, making no mention of the

nationalisation that was to take place that year. |

| Reverting to our anonymous source: "The

completion of the modernisation programme in 1964, meant that the

plant consisted of a high‑top pressure Blast Furnace capable of

producing up to 7,000 tons of pig iron per week, using a variety of

ferrous bearing materials available in the West Midlands, as well as

the conventional iron ore burden now arriving from world wide

sources as well as the Northamptonshire deposits. |

Workers leave at the end of

the day with Elisabeth, under construction, in the

background. |

|

Elisabeth in the course of

construction. |

"The Melting Shop contained two 1,000 ton

inactive mixers, for storing molten pig iron. Seven all‑basic

Magnesite lined Open Hearth Furnaces, each with a capacity of 120

tons, were capable of making all the range of carbon steels,

together with a range of low alloy steels up to 4% Chromium. The

furnaces were now fired with heavy fuel oil atomised with steam;

oxygen enriched the pre-heated air, enabling them to reach

temperatures of 1660 degrees centigrade, and reducing tap-to-tap times to an average of

seven hours". |

|

"The addition of a Ruhrstahl Heraeus

Degassing Plant allowed for the removal of hydrogen and nitrogen

gases and, more importantly, non‑metallic inclusions.

This enabled

steel to be made to a very high standard of cleanliness". |

Elisabeth completed. |

|

Elisabeth casting side

foundations. |

"The pit‑side had been modified to cast all

mill ingots in casting bogies, with facilities to cast forging

ingots up to 42 tons in a special bag, and Rotary Forge ingots for

tube making in the North and South Side Shops. A separate Mould

Preparation Shop had been constructed to prepare ingot moulds and

casting plates to ensure that all the steel could be bottom poured". |

| "A new mill constructed by Schloemann

completed the redevelopment on the Bilston site and this enabled an

extensive range of rounds to be rolled. But blooms, billets anal

slabs could also be produced to absorb the extra production from the

steelworks, and this lead to the making of steel for engineering

uses". |

Elisabeth base and copper

stoves. |

|