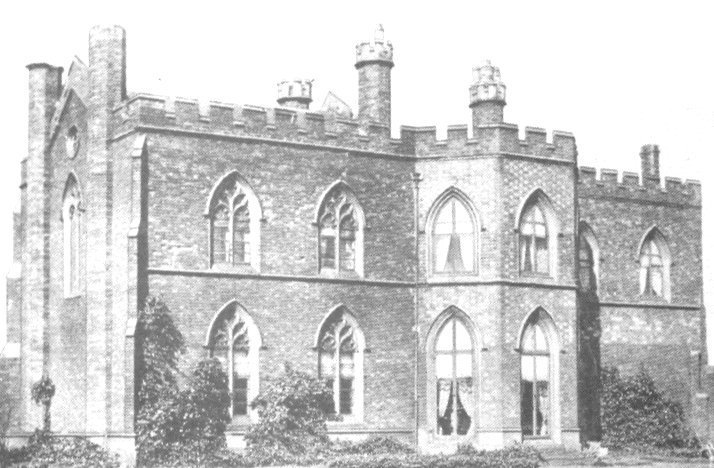

Toll End Hall was built in about

1760 and later the home of the Bagnall family who were

ironmasters. It was later owned by James Solly the

industrialist from Great Bridge. |

|

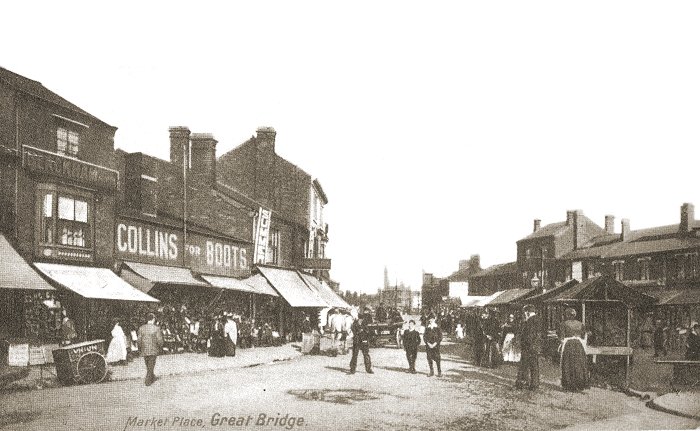

In the latter part of the 19th century, Tipton and the

neighbouring towns became more prosperous thanks to the

many industries that thrived in the area. Employment was

high, and numerous businesses were set up to supply the

needs of the local population, which increased as people

moved into the area to find employment. |

| |

|

| View the Tipton entry

in Harrison, Harrod & Company's 1861 Directory |

|

| |

|

|

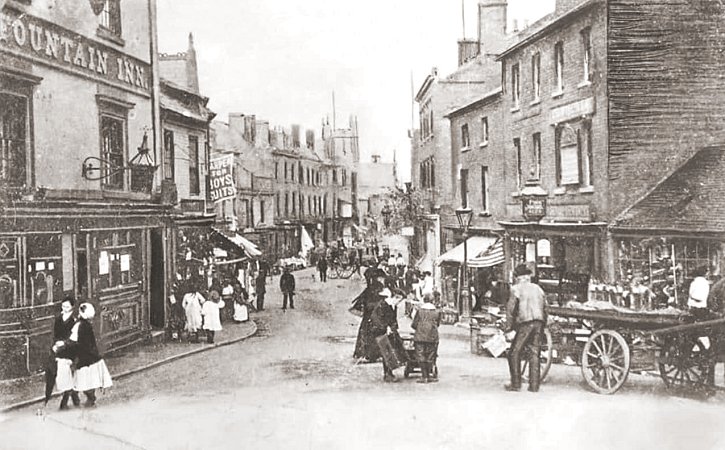

Owen Street. From an old

postcard. |

|

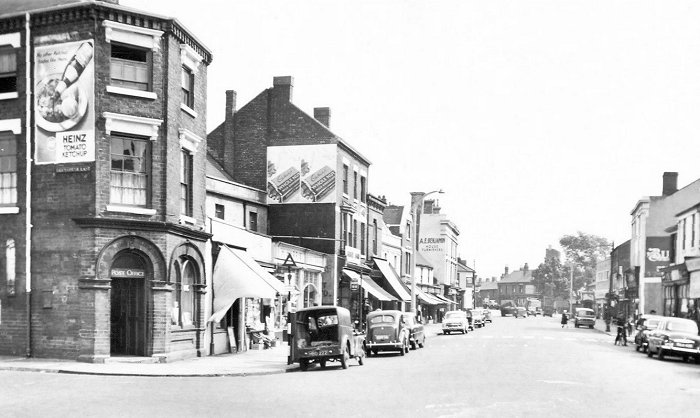

Post Office

One of the amenities that

appeared in the late 1840s was the town’s first post

office, which opened in a small part of a house at

Dudley Port, on the corner of Park Lane and Horseley

Heath. The original postmaster was Mr. Partridge,

who was succeeded by his sister Martha Partridge.

After her death, her niece, Miss Baker took over in

1866. In the early years, letters were received and

despatched twice a day.

At first, mail was conveyed on

the stage coach that ran between Worcester and

Birmingham. The horses were changed at Kidderminster

and at the ‘Swan’ at Swan Village. There were two

letter carriers who sorted the letters in an

outhouse attached to the post office, before making

deliveries. Letters cost one pence or two pence to

send.

The post office was soon

enlarged and took over the whole of the front room

of the house. Sub post offices soon opened at Great

Bridge, Tividale, Tipton Green, Princes End, Ocker

Hill, and Burnt Tree. When parcel post was

introduced, the main post office was again enlarged,

so as to cover the whole of the ground floor. The

average number of letters etc. handled by the post

office increased from 16,700 in 1861 to 43,700 in

1891. Similarly the number of parcels and telegrams

rapidly increased.

In June, 1888, Mr. John Lees

Taylor became postmaster. Around the same time,

eight additional wall boxes were erected in various

parts of the parish and the main office remained

open until 9 pm. for telegrams. Some of the early

postmen, including George Whitehouse, who worked

from Great Bridge became well known local figures.

On the 21st December, 1896 a

splendid new post office, designed by Henry Tanner,

opened at 36 Horseley Heath, at its junction with

Horseley Road. In 1904, on weekdays, it opened from

half past six in the morning until ten o’clock at

night, with four daily parcel deliveries. By 1912,

Robert Crerar had become postmaster. |

|

Great Bridge Post Office. From an

old postcard. |

|

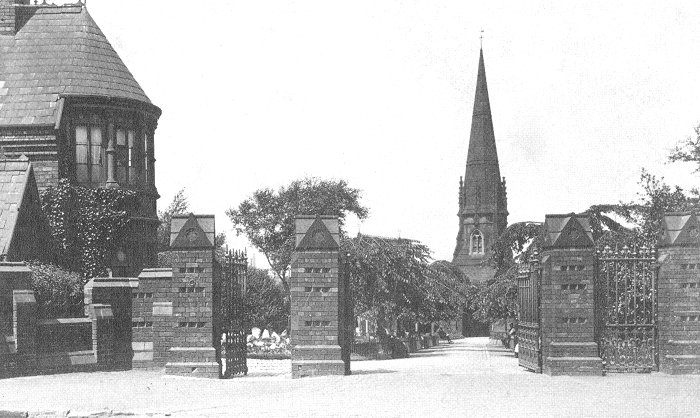

Castle Road, Tipton. From an

old postcard. |

The main entrance to Tipton

Cemetery in Alexandra Road, with the lodge on the

extreme left. From an old postcard. The spire in the

background was in the centre of two mortuary chapels,

now demolished. The cemetery was opened in March 1873 by

the Bishop of Lichfield, Dr. Maclagan. |

| Police Station In 1864, Tipton's police station in Lower Church

Lane opened in a fine blue-brick building that also

housed the magistrate's court. By 1912 there were three

other small police stations in the town. Lower Church

Lane Police Station survived until 2006, when it was

demolished and replaced by the current building, which

opened in March 2007.

The Coneygre Reservoir

The South Staffordshire Waterworks

Company decided to build a reservoir and a pumping

engine to boost the supply of water to Dudley and West

Bromwich. The plan was to build a reservoir at Hill Top

over the railway tunnel in Tunnel Street, but the Great

Western Railway refused to allow its construction.

After this disappointing start, the

company managed to purchase six acres of land on the

Coneygre Estate from the Earl of Dudley, at a cost of

£3,744. Work on the open reservoir began in 1861. It was

built by John Aird & Sons of London and had been

completed by March 1862. The reservoir was on the

southern side of Park Lane West, to the north of the

Birmingham Canal. The reservoir was 200 feet wide (at

its widest point) and could hold eight million gallons

of water, none of which went to Tipton.

There were two 50 hp. steam engines

and four Cornish boilers, housed in a building close to

the canal, to allow for the easy delivery of consumables

etc. The engines used around 4½ tons of coal every

twelve hours, which mainly came from the nearby mines,

owned by the Earl of Dudley. The reservoir operated in

conjunction with a higher reservoir at Shavers End,

Dudley, where water could be pumped when necessary along

a 15 inch water main that was laid alongside the South

Staffordshire Railway Line which ran to Dudley. The

reservoir ceased to be used in 1876, but the pumping

engines continued in use for some years to boost the

water supply to the higher parts of Dudley.

As the water evaporated and the

reservoir emptied, it was used as a site for tipping

surplus soil. A house was built alongside the reservoir

in 1881 and 1882. It was used as part living

accommodation and part offices for the Tipton waterworks

superintendent. Today the site is used for the storage

of pipes etc. and is now occupied by Integrated Water

Services Limited.

Tipton Gas Works

Tipton’s first gasworks officially opened on Saturday

the 1st July, 1882. It stood on a site that had been

purchased from the Tipton Green Colliery Company by the

Local Board. Its location was between the Stour Valley

Railway and Workhouse Lane (now called Alexandra Road),

about 200 metres from Tipton Railway Station. There were

sidings from the railway and a canal basin so that coal

could easily be transported there. The gas works

produced town gas by heating coal in retorts. For many

years Glover West vertical retorts were used, until 1954

when they were replaced by a Woodall Duckham vertical

retort plant, which operated until 1960.

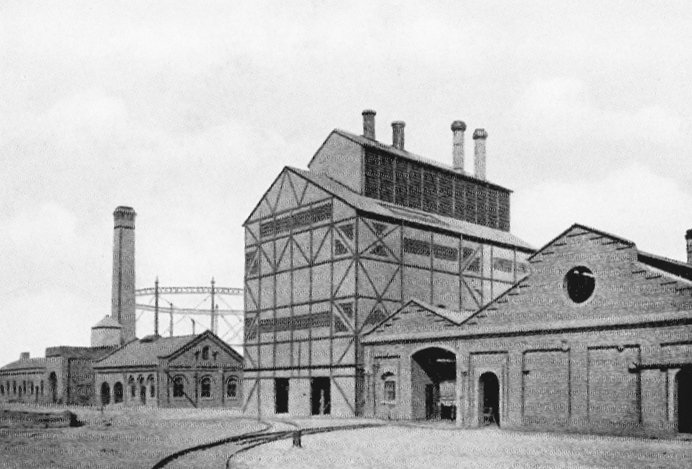

The gas works.

Coal was delivered to the stockyard by rail where it was

tipped from wagons by a rotary tippler and dropped into

a crushing machine before being piled into a heap, which

was continuously monitored for temperature changes, due

to the danger of spontaneous combustion.

Coal was transferred to the retort

house in one of two continuous bucket conveyors that

carried it to the coal storage bunkers from where it

passed through a gas-tight valve into a much smaller

hopper, which opened directly into a retort. In the

retort it was heated up to 1300°C and the gas given off

was removed through pipes for purification.

Eventually the coal was turned into

red hot coke that was quenched by a steam jet. The coke

was dropped into one of two longitudinal conveyors and

transported to the screening plant where it was graded

into sizes and stored in large bunkers, before being

sold.

Tipton Gas Works.

Impure coal gas was taken from a

retort through a cast-iron off-take pipe where any

solids were removed. The hot gas then passed through the

primary condenser where the bulk of the tar and some of

the ammonia were removed to leave partially clean gas.

This then passed into a large cast-iron ammonia scrubber

where layers of wooden grids, sprayed with softened

water, created a large wet surface that readily

dissolved any ammonia in the gas.

The gas continued its journey by

passing through secondary condensers that removed any

remaining ammonia before passing through layers of

iron-oxide to remove hydrogen sulphide. The gas was now

sufficiently pure and passed through a gas meter before

being stored in one of Tipton’s four gasholders.

The by-products from the manufacturing process were all

sold, including tar, ammonia, coke, and sulphur. The tar

was pumped into a storage tank before being delivered to

Midland Tar Distillers by canal boat.

|

Tipton Gas Works seen

from the bowling green in Victoria Park.

From an old postcard. |

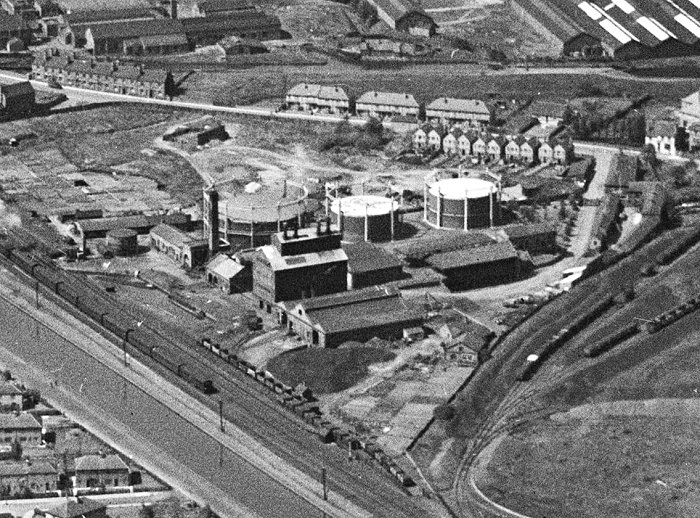

The Mond Gas Works

To the east of Tipton Gas Works was

a site occupied by the South Staffordshire Mond Gas

Company that produced Mond gas for power

and heating purposes. The gas was supplied to a large

area stretching from the edge of Birmingham to the

boundary of Wolverhampton, and as far as Pelsall and

Stourbridge. It was formed by an Act of Parliament in

1901 to make and distribute producer gas across an area

of 123 square miles. Mond gas was a variant of

producer gas in which coal was completely converted to

ash, rather than to coke, as would happen in a retort.

|

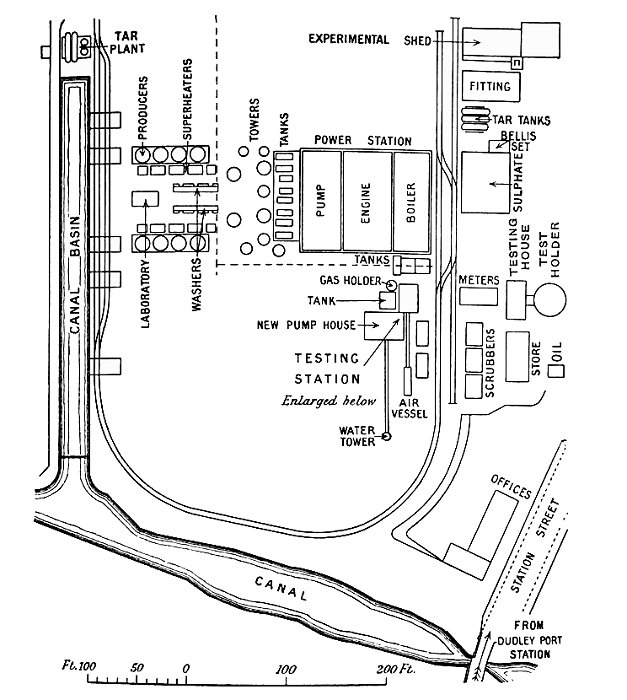

The site at Tipton was built in

1902, beside the Stour Valley Railway Line and the

Dixon’s Canal Branch, just to the east of Tipton’s Gas

Works. It was the largest example of a producer gas

plant in the UK.

The plant had 32 producers, capable of

handling over 600 tonnes of coal per day. Most of the

plant, including the producers, the ammonia recovery,

gas washing and cooling equipment were all duplicated to

ensure a reliable supply.

The gas was compressed and

distributed from the plant at a pressure of 10 pounds

per square inch into asphalt-covered steel gas mains.

This was the first example of a

high-pressure gas network in the UK. Later the plant was

fed from coke which resulted in gas with a lower

calorific value. When this happened, gas from the plant

had to be mixed with conventional coal gas from Tipton

Gas Works, to enrich its calorific value. The Mond gas

works closed in 1963. |

|

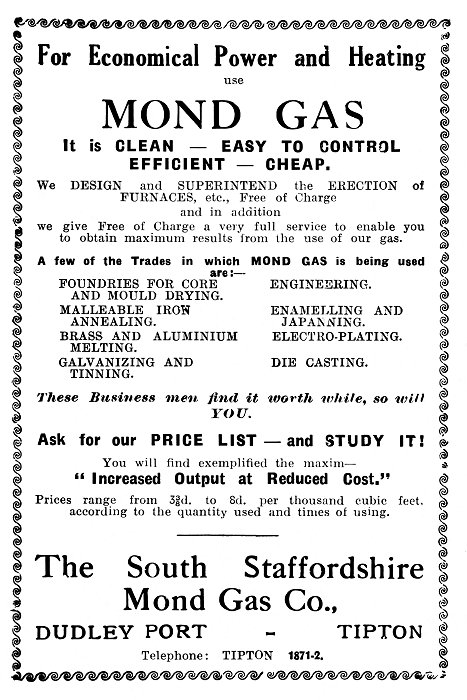

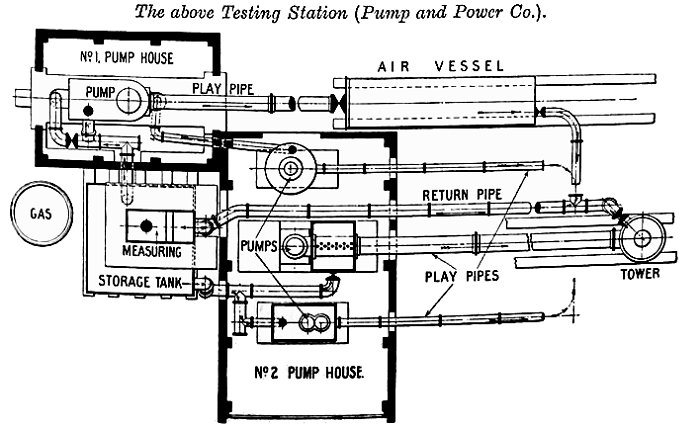

A report of the

Institution of Mechanical

Engineers visit to the South

Staffordshire Mond Gas (Power

and Heating) Company in 1910

The South

Staffordshire Mond Gas (Power

and Heating) Co. was formed by

special Act of Parliament in

1901 to make and distribute gas

for power and heating purposes

over the area extending from the

City of Birmingham boundary on

the one hand to the

Wolverhampton Borough boundary,

and from Pelsall to Stourbridge

on the other; an area of about

123 square miles, having a

population of very nearly

three-quarters of a million, and

comprising the Boroughs of

Dudley, Smethwick, Walsall,

Wednesbury, West Bromwich, and

Wolverhampton; the Townships of

Amblecote, Bilston, Brierley

Hill, Coseley, Darlaston, Heath

Town, Lye and Wollescote,

Oldbury, Quarry Bank, Rowley

Regis, Sedgley, Short-Heath,

Stourbridge, Tipton,

Wednesfield, and Willenhall; and

the Districts of Halesowen,

Kingswinford, and Walsall

(including Bentley). It is what

may very aptly be termed the

industrial heart of England. The

site at Dudley Port, Tipton,

covers an area of about 40

acres.

The first

section of the works was begun

in 1902, and completed and gas

made early in 1905. The plant

comprises eight producers, each

capable of gasifying 20 tons of

fuel per day of 24 hours, and

generating sufficient gas to

drive gas-engines of 2,000 hp.

continuously. The total capacity

of the present section is thus

equal to 16,000 h.p. The fuel is

brought by boat into the canal

basin, or by rail on to the

siding, both of which have been

specially constructed, and is

unloaded by hand into bunkers;

the entrance to these from the

boats is a little above

water-level, and at the

ground-level from the trucks.

From these

bunkers the fuel is

automatically fed into two

"Hunt" conveyers, each having a

capacity of 40 tons per hour,

and which convey and distribute

the fuel into the storage

bunkers over each set of

producers. The bunker over each

producer will hold 40 tons. The

conveyers are driven

electrically, the motors being

about 5 hp.

The gas

after leaving the producers—at

about 550° C.—is thoroughly

washed in mechanical washers,

and after passing through the

ammonia recovery and gas-cooling

towers, is further purified by

large centrifugal fans (two of

which are running in series at

850 revolutions and are driven

by motors of 45 hp. each), and

then passed through the

scrubbers and the meters, before

being compressed and sent

through the mains for

distribution.

The

air-blast for working the

producers is produced by Roots'

blowers (made by Thwaites

Brothers), of which there are

three, each of 50 hp. The

Lee-Howl water-pumps can each

pump 160 tons of water per hour.

All the fans, washers, etc., are

operated electrically, and the

works, which are run constantly

night and day, are also lighted

by electricity, the current

being generated by Westinghouse

three-cylinder vertical

gas-engines, each of 250 hp.;

the voltage is 220. There are

two of these engines, one only

running at a time, the other

being kept as a stand-by.

The three

compressors (made by Fraser and

Chalmers) are used for forcing

the gas through the mains. Each

compressor is of 450 hp., and

will compress 500,000 cubic feet

of gas per Lour. Large

quantities of steam are required

for working the plant, and this

is provided by four Climax

boilers each of 500 hp., capable

of evaporating 1,500 gallons of

water per hour, at a working

pressure of 160 lb. per square

inch. Sulphate of ammonia is

recovered by evaporation in

specially constructed stills,

the crystallized sulphate being

afterwards dried in

hydro-extractors. The gas is

measured by being passed through

rotary meters, each capable of

passing 500,000 cubic feet per

hour.

Mains

varying in size from 36 inches

in diameter at the works to 21

inches at the end of the

circuitor of the trunk main have

been laid, and are filled with

gas through Toll End, to Ocker

Hill, where the main bifurcates,

one leg passing through Bilston

into Wolverhampton, the other

leg passing through Leabrook and

Wednesbury into Walsall. Gas is

at present being distributed

under a pressure of 5 lb. per

square inch. This pressure is

reduced on consumers' premises

by means of reducing valves,

which have been specially

designed for the purpose, to the

pressure suitable for each

individual case. The trunk-mains

are of the Ferguson locking-bar

type.

All other

pipes (except specials) are made

of wrought-iron, or steel, with

screwed joints. The total length

of trunk and branch-mains laid

to end of 1909 was 251 miles.

The gas is connected to over 100

works, and is used for all kinds

of metallurgical and heating

operations, as well as for

generating power by means of

gas-engines. |

|

Trams

The first trams in Tipton were

operated by the Birmingham and District Tramways Company

Limited, formed on the 29th July, 1871. The company

constructed a 4ft. 8½ inch gauge, horse-drawn tramway

under the terms of the Birmingham and Staffordshire

Tramways Act of 1870. It ran from Hockley Brook through

Handsworth to West Bromwich. At Carter’s Green there

were two branches, one to Hill Top and another that ran

to Great Bridge and Dudley Port.

The line opened on the 20th May,

1872 but did not pay its way. The Carter’s Green to

Dudley Port section closed in December 1873 and the

track was soon removed.

On 28th November, 1878 the South

Staffordshire and Birmingham District Steam Tramways

Company Limited, later called the Staffordshire Tramways

Company Limited, was formed to construct and promote

tramways in Staffordshire. It was initially allowed to

operate steam-powered trams under the terms of the

Staffordshire Tramways Order, 1879, confirmed by the

Tramways Orders Confirmation Act, 1879. The company's

headquarters and tram depot was in Corns Street,

Darlaston, off Birmingham Street. The company also had

three small depots, one in Dudley at the end of Tipton

Road, opposite the entrance to Dudley Railway Station,

another on Holyhead Road, Handsworth, near the city

boundary, and a third in Bloxwich Road, Leamore,

Walsall, near the railway line, where the industrial

estate is today. Over the next few years, further

acts of Parliament allowed the company to build and

operate an extensive network, covering much of the Black

Country. The acts and authorised tramways

that ran through Tipton can be summarised as follows:

|

Tramways Orders Confirmation (No. 2) Act, 1881. Tramways

in West Bromwich and Great Bridge

A tramway from Carter’s

Green, West Bromwich, to the Stalk Inn on the boundary

of Great Bridge and Tipton, via Dudley Street, Great

Bridge Street, and Great Bridge.

The

South Staffordshire Tramways Order, 1881. A tramway in

Wednesbury and Tipton

From the White Horse Hotel, Bridge

Street, Wednesbury, to a terminus at the junction of

Birmingham Road and Tipton Road, Dudley. The route

followed Holyhead Road, Victoria Street, Great Western

Street, Leabrook Road, Gospel End Road, Wednesbury Oak

Road, Bloomfield Road, Dudley Road, and Tipton Road,

Dudley.

The

Dudley and Tipton Tramways Order, 1881. Tramways in

Tipton and a short length of track in Birmingham Road,

Dudley

A tramway from Great Bridge

Street, Tipton to the parish boundary in Burnt Tree

Road, via the Market Place, Horseley Heath, and Dudley

Port Road, and a tramway from Great Bridge Street, Tipton to Ocker

Hill, via the Market Place, New Road, and Toll End Road.

|

|

|

|

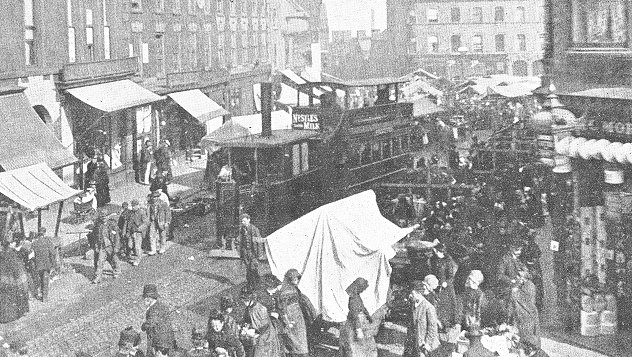

A steam tram passing through

Wednesbury market. |

|

The tramways had a gauge of 3ft. 6

inches, and were mostly single track with passing

places, although a few short lengths of double track

were installed. Stand pipes were also fitted between the

tracks at convenient stopping places to refill the

engines’ water tanks.

On the 12th October, 1885, the

Great Bridge to Tipton Road, Dudley section opened. The

average fare per passenger was 1.49 pence. The company's

annual profit was £2,416.

On Saturday, 10th September, 1887,

a fatal accident occurred on the reversing triangle at

the Dudley terminus. A Birmingham and Midland car was

standing on the triangle with the rear of the passenger

car just clear of the points as a South Staffs car came

down from Dudley, bound for Wednesbury. The engine took

the points, but the car jumped them and crashed into the

rear of the other engine, fatally injuring a woman

passenger who was boarding the Birmingham and Midland

car.

The last remaining steam-powered

trams operated by the company were on the Wednesbury to

Dudley via Tipton line. There were serious doubts about

electrifying the route because mining subsidence was

causing a lot of trouble and expense. In a letter

to Tipton Urban Distrect Council in June 1904, the

company stated that a report received from its mining

engineer in regard to the subsidence on this road was

of "a most unfavourable character". It stated that if

the new owners of the Bloomfield Ironworks availed

themselves of the mining rights, which went with the

property, further subsidence would take place. In the

event of electrification being proceeded with,

deflections of the line would cause a leakage of current

at the joints. Under the circumstances, the Directors

were unable to proceed with the electrification as

requested by the council.

Earlier in the year, the company

had applied to the Board of Trade for a further

extension to operate by steam power, although this had

been granted, both Tipton and

Wednesbury Councils had represented to the Board of

Trade that inhabitants of the district would prefer to

be without the service. In view of the fact that steam

operation had ceased on the Handsworth section and as

the company stated, the maintenance of all the remaining

steam services during 1903 had involved the company in

considerable loss, all remaining steam services would

end. The Wednesbury to Dudley via Tipton route closed on

the 15th June, 1904.

On the 24th January, 1903 the

company (now the South Staffordshire Tramways (Lessee)

Company Limited, extended its electrically-powered

Handsworth service to Great Bridge. The company also

began to run electrically-powered trams on the route

from Wednesbury to Dudley via Princes End on the 22nd

October, 1907.

|

|

A South Staffs tram outside the

company's generating station at James Bridge. |

|

Steam-powered trams were also

operated in Tipton by the Birmingham and Midland

Tramways Company, founded on the 22nd November, 1883 to

operate over authorised lines that were to be built by

the Western Districts Company, at extremely low rates.

The lines were authorised by the Board of Trade, as the

Birmingham and Western District Tramways Order, 1881,

and confirmed by the Tramways Orders Confirmation (No.

3) Act, 1882. The lines formed a large interconnected

network with around 35 miles of track, crossing

Birmingham, Smethwick, Oldbury, Tipton, Dudley, Sedgley,

and Coseley.

The acts and authorised tramways in

Tipton can be summarised as follows:

|

Tramways Orders Confirmation (No. 2) Act, 1881. Tramways

in Birmingham

A tramway from Dudley Road,

Birmingham to Smethwick High Street and Oldbury, then to

Dudley Port Road, Dudley via Dudley Road and Tividale

Road, and ending at Dudley Market Place. The last part

of the route through Dudley Port opened on the 30th

August, 1885. Electrically-powered trams started to

operate on the route on the 21st November, 1904.

Tramways Orders Confirmation (No. 3) Act, 1882. Tipton,

Sedgley, and Coseley

A continuation of

the tramway from Dudley Road to Sedgley Road West via

Tipton Road, Sedgley Road East, Park Lane to Coseley.

|

|

The Board of Trade inspection was

carried out by Major General Hutchinson on the 1st June,

1885, and Board of Trade Certificates to allow trams to

run in Oldbury, West Bromwich, Tipton, Dudley, and

Rowley Regis were received on the 4th July, 1885.

The company’s depot was built on 3½

acres of land in Oldbury Road, Smethwick, about 300

yards west of the junction with Spon Lane. Large engine

and car sheds were built, along with a coke yard, off

Windmill Lane, Smethwick. The company purchased 34

tramway locomotives.

|

|

A tram in Gospel Oak Road, with

Ocker Hill Junior School in the background. From an old

postcard. |

|

Education and Schools

In the early part of the 19th

century there were many Sunday schools attached to

various churches and chapels, as well as several

privately-run schools. There were also a few others that

placed themselves under Government inspection and

received Government grants. They were known as public

elementary schools and tended to be the best local

schools of the day. They included St. Martin's School,

Lower Church Lane; St. Mark's School at Ocker Hill; St.

John’s School, Park Lane; Great Bridge Wesleyan School,

Fisher Street; Tipton Hall School; and Waterloo Street

Infants School. They could accommodate 1,943 pupils.

There were also National Schools, supported by private contributions. They were

at Horseley Heath, Ocker Hill and Tipton Green and

catered for around 500 children.

In 1871 the following schools were

supported by voluntary contributions:

Zion School, Princes End

St. Paul's New Connexion School,

Dudley Port

Mr. Beasley's Wesleyan School,

Dudley Port

Primitive Methodist School, Burnt

Tree

Bloomfield Wesleyan School

Gospel Oak Wesleyan School

Ragged School, Brown Lion Street,

Bloomfield

Summerhill Wesleyan School

The Tabernacle School, Princes End

Ocker Hill Wesleyan School

Ebenezer Independent School, Union

Street

Primitive Methodist School,

Bloomfield

Primitive Methodist School, Great

Bridge

Ragged School, Horseley Heath |

Tipton School Board was set up

in March 1871 under the Elementary Education Act 1870.

The Board held its first meeting on Thursday, 6th April,

in Lower Church Lane when members elected William Hipkins as Chairman and Samuel Millington as

Vice-Chairman. No clerk was appointed and so the Rev. S.

T. Tozer volunteered to be acting Honorary Secretary at

the board’s next meeting on the 5th July. At the

meeting, Mr. G. Wilkinson, of Lloyd's Bank, Dudley, was

appointed Treasurer. The other members were William

Bristow, James Brown, William Roberts, Joseph Cox, and

William Foster.

In 1871 the average school

attendance was only 1,146, but thanks to the Board it

rapidly increased. New schools were erected by the Board

as follows:

Great Bridge (New Road) in 1874

Dudley Port in 1877

Burnt Tree in 1880

Tipton Green in 1880

Bloomfield in 1891

Ocker Hill in 1899

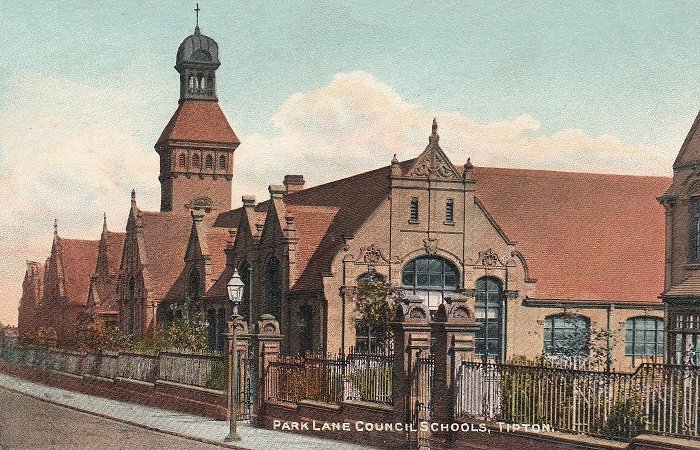

Park Lane in 1903 |

The School board was eventually

superseded by the Council's Education committee. In 1886 the schools could

accommodate 3,032 pupils. The average attendance was 2,681.

Average attendance in other schools

was 2,154.

From an old postcard.

Tipton schools listed in Kelly’s

1912 Directory are as follows:

Birch Street, Park Lane, opened

January, 1905, 355 boys, 355 girls and 330 infants;

average attendance, 318 boys, 301 girls and 302 infants;

W. J. Woodall, master; Miss A. Richards, mistress; Miss

Eliza Booth, infants' mistress.

Bloomfield, Bloomfield Road

(infants), built in 1891, for 254 children; average attendance,

191; Miss Sarah Booth, mistress.

Burnt Tree, Gate Street (mixed),

built in 1880, enlarged in 1896, 415 children; average

attendance, 381; Joseph Yorke, master. Infants'

school, 330 children; average attendance, 249; Miss Florrie Goldie, mistress.

Dudley Port, built in 1877, 380

boys, 272 girls and 285 infants; average attendance, 277

boys, 246 girls and 254 infants; William

Thomas Whitehouse, master; Miss K. Swift, mistress; Miss

A. H. Yorke, infants' mistress.

Great Bridge, New Road, built in

1873, for 400 boys and 257 girls; average .attendance,

340 boys and 257 girls; Charles Henry Greenwood, master;

Miss Louisa Hickinbottom, mistress. Infants' School

built in 1887, for 256 children; average attendance,

181; Miss Elizabeth Walker, mistress.

Ocker Hill, Gospel Oak Road, built

in 1900, for 336 boys and girls and 275 infants; average

attendance, 294 boys and girls and 178 infants; Thomas

Smith, headmaster; Mrs. Keziah Woolley, infants'

mistress.

Tipton Green, Sedgley Road West,

built in 1880, for 315 boys, 296 girls and 316 infants;

average attendance, 264 boys, 259 girls and

222 infants; Arthur E. J ones, master; Miss Edith E.

Given, mistress; Miss Annie Kenny, infants' mistress.

St. John's (infants), Prince's End,

built in 1857, enlarged in 1895, for 160 infants;

average attendance, 119 infants ; Miss Emily Labram,

infants' mistress.

St. Mark's (mixed & infants),

Spring Street, Ocker Hill, built in 1858, for 500

children; average attendance, 174 mixed and 137 infants;

Richard G. Farley, master; Miss Davis, infants' mistress.

St. Martin's, Lower Church Lane,

built in 1861, for 450 boys and girls and 150 infants;

average attendance, 306 boys and girls and 117 infants;

John Smith, master; Miss Alma Bushell, infants' mistress.

St. Paul's, Wood Street, built in

1874 and enlarged in 1899, for 147 boys, 138 girls and

178 infants; average attendance, 119 boys, 108 girls and

138 infants; Samuel Kelsall, master; Miss Florence A.

Clee, mistress; Mrs. Sarah Mould, infants' mistress.

|

|

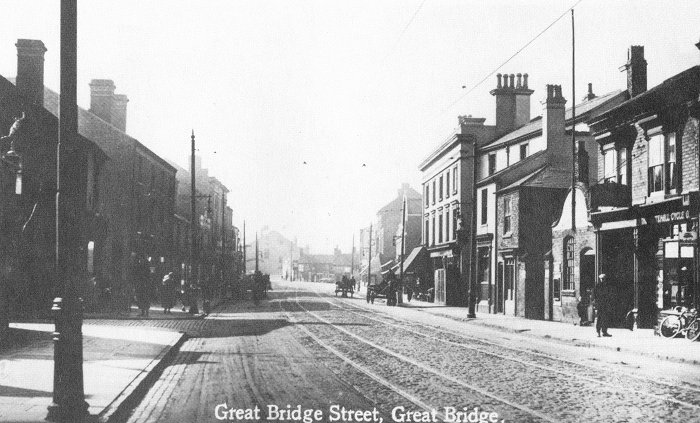

From an old postcard. |

|

From an old postcard. |

|

|

|

|

|

Return to

Industries |

Return to

the

beginning |

Proceed to

Public Houses |

|