|

The Industrial Town

Locks and Keys

|

| Willenhall's manufacturers, like those in the neighbouring

towns, originally worked in small workshops, often in a small

yard behind a family home, where at times the whole family would

be involved in the manufacturing process. As time progressed,

the town's industry was dominated by the lock and key makers. By

the 1850s when lock factories began to appear, there were more than

300 lock makers, 90 key makers, and a dozen or so key stampers,

working in small workshops throughout the town.

As the number of manufacturing firms increased, and the local

transport network improved, large factories were built,

completely changing the Black Country landscape. The factories

increased in size and number. By the Second World War there were

around 200 factories in the town, both large and small, along

with 40 or so workshops.

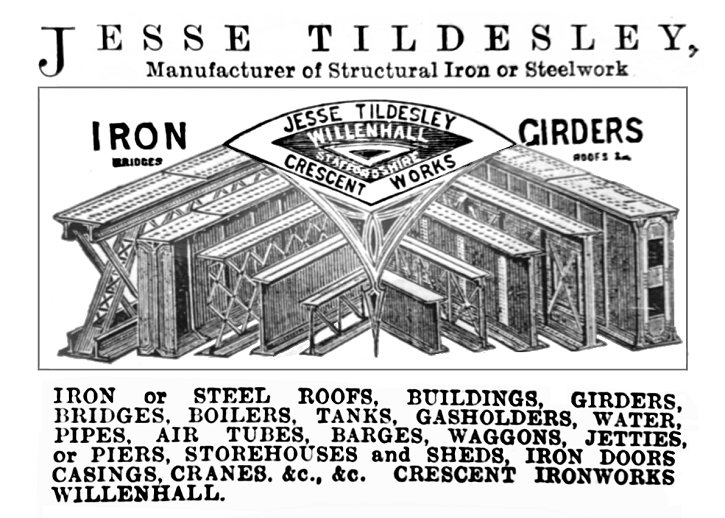

An important development happened in 1830 when James

Carpenter and John Young designed a door rimlock with a perpendicular action,

which led to the development of the modern mortice lock.

Carpenter and Young had a joint patent which they agreed to

divide into two halves, giving Young the right to make mortice

locks, and Carpenter the right to produce a perpendicular action

rim lock, which became known as "Carpenters lift up lock". His

business grew and he built a large factory in New Road, known as

Summerford Works. James' daughter, Harriet married James Tildesley.

When James Carpenter died in 1844, John Carpenter

and James Tildesley inherited

the business, Carpenter and Company, which in 1851

became Carpenter and Tildesley. James dissolved his

partnership with John Carpenter and became the sole

owner of the company. |

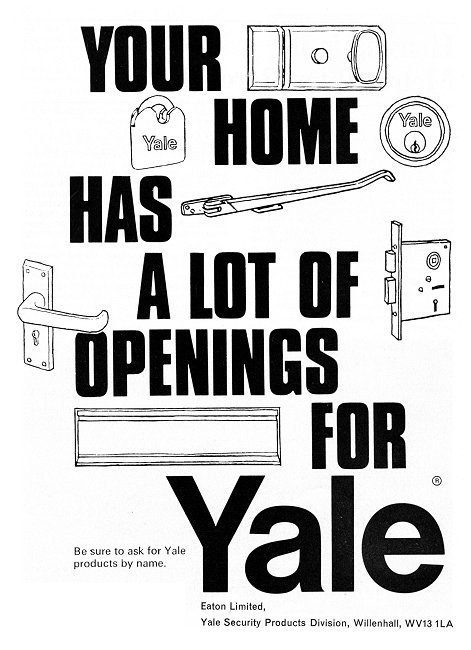

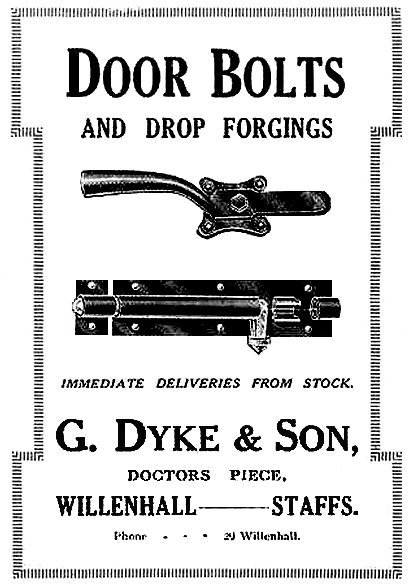

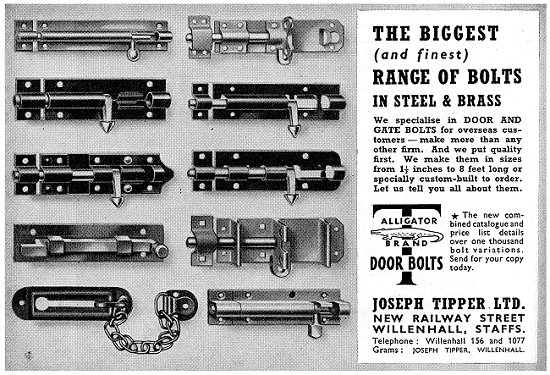

An advert from 1938. |

| James Carpenter was an ardent church goer who

became a Wesleyan Methodist due to the antics of the

Rev. William Moreton, curate of St. Giles' Church.

He was a keen supporter of Wolverhampton's Member of

Parliament, C. P. Villiers, and is buried in a vault

on the east side of Union Street Methodist Church. |

|

An advert from 1938. |

All kinds of locks were produced in the town, including

padlocks, lever locks, and Bramah locks; but another form of

lock, the cylinder pin tumbler lock, would revolutionise the

local industry, leading to several large factories, and greatly

increased production. |

| |

|

| Read a report about a

Willenhall keymaker and his wife in 1841 |

|

| |

|

|

|

|

|

Two adverts from 1938. |

|

|

An advert showing a pin

tumbler lock, from 1938. |

One of the town's largest lock factories, which stood in Wood

Street, was originally built by H. and T. Vaughan, a business established

in 1856 by Henry, William and Thomas Vaughan, the sons of lockmaker

Able Vaughan. On

6th December, 1869 Willenhall Local Board approved plans for the

factory in Wood Street, and in 1872 approved plans for a second

factory in Union Street.

Around 1910 the company extensively

developed the cylinder pin

tumbler lock which had been invented in America by Linus Yale,

and improved by his son Linus junior. The lock became extremely

popular, and few houses were without them. |

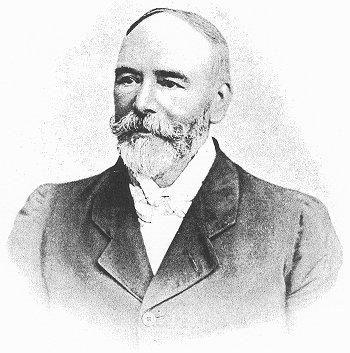

| H. and T. Vaughan became the largest

manufacturer of door locks in the world.

Henry Vaughan, son of Abel

Vaughan. He was educated at Wolverhampton Grammar

School, and became a Justice of the Peace for

Staffordshire, and President of the Wolverhampton

Chamber of Commerce. He was also a County Councillor,

and a member of Willenhall School Board. |

|

|

An advert from 1938. |

Thomas Vaughan also became a Justice of the

Peace for Staffordshire.

In 1935 two bells were given to St. Giles' Church

as a memorial to Mr. and Mrs Henry Vaughan.

In 1928, when Vaughan's managing director,

Joseph Starkey died, the family decided to sell

their business to the American firm, Yale and Towne

Manufacturing Company, the original inventors of the

lock.

|

| This allowed the American company to begin

producing the 'Yale' cylinder pin tumbler lock in

the UK with a ready made factory and workforce. Cylinder pin tumbler locks were also made in

Willenhall by Josiah Parkes & Sons, Enoch Tonks & Sons, Arthur Shaw &

Company Limited, Century Locks Limited, and J. Legge. |

|

|

|

Two adverts for padlock manufacturers,

from 1938. |

| |

|

| Read Samuel

Griffiths' description of Willenhall and

its industries in the early 1870s |

|

| |

|

|

| Originally

all lock parts were hand made, often being filed from square or

round iron bars. Other parts were forged on the anvil then filed

to final size and shape. Holes were punched-in on a vice, or

anvil, and drilled with a bow and stock. A file was one of the

most important tools used by the lockmaker. Children of only 9

or 10 years old were taught to file, which they did

for many hours each day, continually bending over their work. As

a result of starting at such an early age, many of them

developed humped backs, twisted shoulders, and even bent legs,

which led to the town's nickname "Humpshire".

Some public houses

even had hollows in the wall behind the bench seats, so that

customers could sit upright, with their hump in the hollow. |

An advert from 1938. |

|

|

|

|

Two adverts for cabinet lock

manufacturers, from 1938. |

|

|

An advert from 1938. |

It took a long time for the lock industry to be

mechanised. Low wages meant that large numbers of

people could be employed in the industry, turning

out vast numbers of locks by hand.

The manufacturing

process was speeded-up in the late 1830s when cheap

malleable iron castings became available. The cast

parts were accurately produced and only needed a

little filing to clean them up, and finish them off.

This process also simplified key making with the

introduction of key castings.

Another

manufacturing aid came in the form of the fly-press developed by

Isaac Mason. The press allowed large numbers of parts to be

quickly and accurately pressed out from a die, saving much time

and labour. |

|

|

|

|

Two adverts for rim and dead lock

manufacturers, from 1938. |

|

The most important lockmakers in the town in the late 1800s

included:

Beddows & Sturmey

Carpenter & Tildesley

John Harper and Company Limited

William Harper

Joseph Legge

and Company

John Miners & Sons

Enoch Tonks & Sons

J. Waine &

Sons

H & T. Vaughan |

|

An advert from 1938. |

|

|

|

|

Two very different adverts from Josiah Parkes,

the one on the left from 1938, the other

from 1919. |

|

The former offices of Josiah Parkes &

Sons Limited, demolished some years ago.

An advert from 1974.

|

An advert from 1938. |

Eventually the industry did become more mechanised, often with

special-purpose machines that were tended by female workers. The various

components were made by machine, with the final assembly and

finishing carried out by skilled locksmiths. As a result, the

manufacturers produced a vast array of different locks, for

almost every use, and supplied many industries such as

shipbuilding, aircraft building, military vehicle makers, and

the railways, both at home and abroad. Willenhall greatly

prospered thanks to the lock industry, which

survived until recent times. Sadly it began to

decline in the late 1980s, due in the main to

cheap foreign imports. Many businesses were

taken over, or amalgamated, and many others soon

disappeared.

|

| In its heyday there were over 4,000 people

employed in the town's lockmaking

industry, but this number rapidly reduced in the 1990s, until

today only a handful of skilled lock makers remain. |

|

If you want to read more about the local lock making firms,

please look at the Gazetteer of lock and Key Makers, which is

also on this website. Because of this, I have deliberately kept

the description of the industry short, rather than duplicate

what is already there.

| View the Gazetteer of

lock and Key Makers |

|

|

An advert from 1938. |

An advert from 1938.

|

One of the last

workshops in the town where locks are still

made. It belongs to A. Lewis & Sons.

The company still

manufactures high quality brass cabinet locks. |

Part of A. Lewis & Sons workshop.

|

An advert from 1938. |

Like its neighbours, Willenhall had a wide variety of

manufacturers, producing all kinds of metal goods.

There were

brass foundries, die sinkers, drop forgers, grey iron and

malleable iron foundries, bolt manufacturers, and companies

producing all kinds of presswork.

Willenhall became famous throughout the Black Country for its

grey iron castings produced by such firms as John Harper,

William Harper, Charles Perks, William Horton, and Thomas Pedley.

Large numbers of malleable iron castings were

also made in

the town.

Malleable iron was cheaper than steel, and just as

good for many applications. Castings were produced by Charles

Perks, Star Foundry, John Harper, William Horton, and at many

other local foundries.

|

| In 1917 Josiah Parkes & Sons Limited acquired Wolverhampton

based Crane Foundry, where large numbers of castings of all

kinds were produced. Crane Foundry remained in their hands until

1945 when it was sold to Qualcast.

There were also foundries producing non-ferrous castings,

including C. & L. Hills, J. Parkes junior, Pioneer Castings,

Wye Foundry, and Knowles Foundry.

|

An advert from 1958. |

An advert from 1953.

An advert from 1953.

A company letterhead from 1936.

| John Harper was second son of John Harper

senior, a hardware merchant in Willenhall. John

Harper junior became a Justice of the Peace for

Staffordshire, County Councillor for North Bilston,

and served on the Willenhall School Board. He was a

staunch Liberal, and close friend of C. P. Villiers,

M.P.

He was a prominent Wesleyan and a lifelong

teetotaller. As well as being the principal

shareholder, chairman of the directors, and general

manager of John Harper & Company, he was proprietor

of the Bilston Windmill Cement and Plaster Company,

and a Fellow of the Imperial Institute.

He extensively travelled throughout the world. |

John Harper junior. |

|

|

| Albion Works, one of the oldest factories in

Willenhall, run by John Harper & Company Limited,

was founded in 1790. The firm not only

produced locks, but also a wide range of

products.

Read a history of the

company |

|

| |

|

| |

|

|

Read the story of 'The Old Works', produced

by John Harper & Company Limited in 1950. |

| |

|

| |

|

Read an

Albion Works Bulletin from John Harper &

Company Limited

for June 1951. |

|

| |

|

|

Another once-well-known Willenhall company

was Ash Foundries Limited in Wood Street,

founded in 1908. The firm originally traded as

Arthur Ash & Company until 1948 when it became a

limited company. All kinds of small repetition

grey iron castings were produced for many

industries, particularly the local lock trade

which required small thin-section machineable

parts.

In the late 1940s the foundry was

rebuilt and new machines were added to widen the

product range to include castings for textile

and agricultural engineers. There was also a

jobbing section where larger castings could be

produced, and an up-to-date pattern shop. The

larger castings included press beds for machine

tool manufacturers. |

An advert from 1954.

An advert from 1953.

An advert from 1953.

From the 1976 edition of the

Walsall Official Handbook.

An advert from 1976.

An advert from 1974.

|

An advert from 1954. |

William Harper Son & Company were another

firm, specialising in repetition work,

particularly for engineering firms, and the

motor trade. The business was based at Star

Foundry in Birmingham Street, where castings

were produced in malleable and soft iron.

Many of Willenhall's foundries were great

innovators, constantly developing new techniques

to keep ahead of the competition. One such

company, A. Fryer & Sons Limited, founded in

1903, produced castings using the Shell method,

which were cleaner and more accurate than

castings made using traditional techniques. The

castings had such a fine finish, and were so

accurate that machining was often unnecessary.

Castings were produced for a wide range of

industries, in particular electrical

engineering, building and the motor trades.

The factory had a modern shot blast plant

where work was done for outside companies, and a

large stock was kept of chill cast phosphor

bronze rods, both solid and cored, for sale to

the trade. |

An advert from 1954.

| H. & J. Hill were based in Walsall Street on

a site purchased from John Harper & Company

Limited. The firm specialised in malleable and

soft grey iron castings for all trades, and

produced annealing pans and hardening pots.

The business went into liquidation on 5th

May, 1981. |

An advert from 1954. |

|

|

Knowles Foundry in John Harper Street was

founded in 1880 to produce small brass castings

for the local lock trade. The firm's product

range greatly changed in the intervening years

to include castings in aluminium alloy,

gunmetal, phosphor bronze etc., for many

industries including electrical engineering,

shipbuilding, and textiles. Aluminium alloy

castings were produced up to two hundredweights,

particularly for petrol and diesel engines, fire

engine-fittings, textile and machine tools,

emulsifiers, traffic signs, bus and coach

fittings, electrical switchgear, lighting

fittings, and outboard engines. Aluminium

gravity die castings were also made. The pattern

shop produced numerous patterns of all kinds for

the trade. |

An advert from 1954.

| |

|

| Read about C. & L.

Hill Limited brass, non-ferrous, and iron

founders |

|

| |

|

| One of Willenhall's notable foundries was

Victoria Foundry in Stringes Lane, run by Arthur

Tipper Limited, grey and malleable ironfounders,

producers of conduit tubes and fittings, and

makers of a vast range of builders ironmongery. |

| The firm produced almost every kind of

builders' fittings including door and gate

bolts, shelf brackets, Suffolk and Gothic

latches, axle pulleys, tee and butt hinges, hat

and coat hooks, shelf brackets, letter plates,

sash fasteners, fanlight stays and catches, and

casement stays and fasteners. Their delivery

vans operated over most of the Midlands, and

their London office and warehouse supplied

London and places as far afield as the south and

east coasts.

Some of Tipper's coat

hooks. |

An advert from 1954. |

|

An advert from 1958. |

|

An advert from 1958. |

|

One of the many local industrial success

stories is that of the Ductile Steels Group,

which started in 1915 when Mr. Frank Hall

acquired a fifty percent stake in Stanley &

Hawker, a steel merchandising firm. He became

sole proprietor in the early 1920s after the

death of his partner. In 1924 Mr. C. H. Batten

joined the firm, and became a partner in 1931.

The business became the largest stockholder of

cold-rolled steel strip in the country,

importing over 6,000 tons per year. In the early

1930s Frank Hall foresaw the coming of the 33⅓

percent tariff that was to be imposed on all

imported steel, and so he decided that the

company should produce its own steel. He purchased two

second-hand cold rolling mills, and had a

'coffin-pot' annealing furnace built in a small

factory on a levelled dirt tip in Stringes Lane.

Within a short time cold rolled steel strip was

in production.

Ductile Steels Limited was formed as a

private company, and two further cold rolling

mills, and a hot rolling mill were installed at

the factory. The business prospered and became a

public company in 1936 incorporating Starkey &

Hawker, whose stock and machinery were moved to

the Stringes Lane site. Although the stocks of

steel strip were gradually

reduced, the stocking and shearing of steel

sheets continued, and became an important part of

the business.

|

An advert from 1958.

| The Willenhall factory expanded again in 1945

when the manufacture of cold-formed sections was

added to the product list. The firm purchased

Sections & Mouldings (Birmingham) Limited and

transferred its plant to the Stringes Lane

site. In the same year the firm purchased The Monmore Green Rolling Mills Company (1924)

Limited at Wolverhampton, which was in

liquidation. The name was changed to Monmore

Conduits Limited, and the factory began to

produce electrical conduits made from Ductile's

hot rolled steel strip. In order to improve

the sales of electrical conduit, the firm

purchased the conduit fittings supplier, Seal

Conduit Company Limited in 1946 and moved the

business to the Monmore Green site. A warehouse

was also opened in Coventry to stock the firm's

conduits, along with fittings, certain

electrical goods, and a quantity of Ductile

steel flats and sheets. 1946 also saw the

formation of Metalon Steels Limited at Jubilee

Works, Short Heath to turn Ductile steel strip

into galvanised coils. In 1947 the firm acquired

press maker Samuel Griffiths (Willenhall)

Limited, based in John Harper Street,

Willenhall to make all of the machinery for the

mechanisation and development of the Ductile

group. |

|

| Expansion continued in 1948 with the

acquisition of Dudley Port Rolling Mills

Limited, of Lower Church Lane, Tipton. This was

one of the most up-to-date and efficient rolling

mills of its kind in the country. The firm

produced rolls, small flats, strip, rounds,

ovals, and special sections in bright drawn and

hot rolled finishes.

This operation was expanded

by the purchase of Shropshire Steels whose

entire operation was transferred to Dudley Port.

In 1953 Ductile formed Ductile Planetary Mill

Limited in Planetary Road, Wednesfield to

operate a newly installed hot steel rolling

mill, the first of its kind.

The new process

called "Planetary Rolling" was named after

Planetary Road. In 1963 the group moved its head

office there. |

An advert from 1976. |

|

An advert from 1938. |

Another important local industry, which still survives today is

drop forging. It began in Willenhall in 1812 when John Grimley

moved here from Birmingham and began to produce

keys, using a drop hammer. The industry rapidly

grew to become an important part of local

manufacturing. A vast range of products were

produced, including bolts, hinges, letter boxes,

staples, and every kind of ironmongery. Parts

were also produced for the shipbuilding industry, cycle

manufacturing, and vehicle manufacturing. |

Some of the main companies were:

Armstrong Stevens

Criterion Stampings

Vaughan

Brothers

A. Vaughan,

E. Nicklin & Sons

Platts Forgings

Victoria Drop Forgings

G. A. Tildesley & Co. Ltd. |

The thud of the drop hammers would have been a familiar sound in

the town.

It could be heard until recently around the premises of

George Dyke Limited in Doctors Piece, now closed, and can

still be heard at W. H. Tildesley

Limited in Bow Street. |

George Dyke Limited in

Doctors Piece, now derelict. |

An advert from 1926.

An advert from 1958.

|

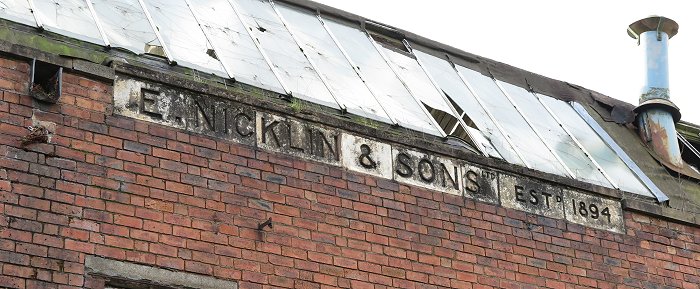

The stone panel on the

side of the derelict factory built by E. Nicklin

& Sons, dropforgers, in 1894. |

~ ~

E. Nicklin & Sons'

factory, now derelict, on the corner of Field

Street, and Round Croft. It was later occupied

by Henry Ellard and Sons Limited. |

|

A final view of the

factory, as seen from Round Croft in January

2015. |

An advert from 1892.

|

An advert from 1884. |

W. H. Tildesley's Clifford Works in

Bow Street.

|

G. A. Tildesley and

Company Limited were one of the larger drop

forging companies in the town.

There were also a number

of patternmakers, such as the Central

Patternmaking Company, catering for the numerous

foundries in the area.

Both adverts are from

1938. |

|

A company letterhead from the mid

1960s.

An advert from 1954.

|

|

|

Two adverts

from 1976. |

|

| Vaughan Brothers (Drop forgings) Limited of

Eagle Works, Somerford Place, Willenhall was founded

in 1874. It became a private limited company in

1936, and went public a year later. All kinds of

drop forgings were produced including parts for

vehicle manufacturers, railway companies, aircraft

manufacturers, aircraft engine manufacturers,

fittings for ships, and parts for agricultural

machinery.

The firm also carried out machining and produced

a number of finished products including jacks, gear

boxes, and many tools. Another product was Eagle

brand spanners.

By the 1960s the company employed over 300

people.

The Firm closed in the recession which began in

the late 1980s. The business was taken over by a

company called Shakespeare, which only lasted for a

short time.

Eagle Works has since been acquired by the

Middleton Paper Company

Limited, paper merchants and convertors,

specialising in paper sheeting, rewinding,

rewrapping, and recycling. |

An advert from the late 1930s. |

A Vaughan Brothers spanner, made for

the GPO in 1939.

| The Middleton Paper Company moved to a new

site and so for several years Eagle Works was

unused. Walsall Council's planning committee

gave permission for the site to be redeveloped

into 1 and 2 bedroom apartments and 2, 3 and 4

bedroom houses. Demolition of the old factory

began at the end of 2022.

An old letterhead. |

A Vaughan Brothers adjustable spanner.

One of the local firms that made parts for vehicle

manufacturers. An advert from 1938. |

Vehicle manufacturers were supplied with all

kinds of pressings from several locally based

firms including Thomas Herbert and Company, George

Carter and Sons, and the Willenhall Motor Radiator Company,

founded in 1919. During World War 2 the company manufactured

parts for the De Havilland Mosquito, and in 1951 began to

produce steel cabs for ERF trucks. In the late 1950s DKR

scooters were built at the factory, and in the 1960s sheet metal

motor components including wings, bonnets, petrol tanks, and

shields were supplied to vehicle manufacturers. Body pressings

and assemblies were also supplied to Ford. The company still

exists today as part of Caparo Modular Systems Limited, a

steel engineering and automotive group, based in the UK, India

and the USA. |

|

|

|

|

Two of the

many local firms producing

presswork in the late 1930s. |

| George Carter (Pressings)

Limited was founded by

George Carter in 1830. He

was a general smith,

specialising in hand-forged

vices and hand and power

presses.

He was succeeded by his

son, also George Carter, who

specialised in hand-forged

press tools.

The firm was then taken

over by the founder's

grandson, Robert Carter, who

improved the firm's

manufacturing processes.

On his death in 1925, his

two sons Arthur and Allan

Carter took over. The firm

became a private limited

company in 1946 and by the

1960s employed around 180

people, producing general

presswork for the motor

trade.

Sadly

George Carter (Pressings) Limited

closed in May, 2009. |

|

An advert from 1958.

|

|

An advert from 1954. |

Another firm, once-well known for high grade

metal pressings was H. & L. Appleby in Forge

Road, Short Heath. The business, founded in

1840 had a well-equipped factory with a toolroom

complete with the latest machine tools, a

jig-boring facility, and a large press shop

housing thirty five power presses with

capacities up to three hundred tons.

A large extension, built in the early 1950s,

was used for the assembly and finishing of the

firm's products, including welding, riveting,

painting, enamelling, and machining.

The firm survived for over one hundred and

fifty years. It was dissolved on 6th October,

1998. |

| Willenhall firms produced component parts for almost every

industry.

Castings and pressings were made for lockmakers (in

grey iron, malleable iron, brass, bronze, and gunmetal), and for

gas stove and cooker manufacturers, bedstead makers, the

electrical industry, tool manufacturers, fittings for travel goods,

vehicle manufacturers, etc., etc. |

One of the few screw

manufacturers in the town. |

|

|

|

|

Two of the

many foundries in the area. |

|

An advert from 1861.

An advert from 1861.

| Another metal working company was the Metal

Products Company (Willenhall) Limited, based in

Neachells Lane. The firm was founded by James W.

Whitehouse in 1908 to reclaim and refine metal.

It originally traded as J. W. Whitehouse & Sons.

The factory included a ferrous foundry, a brass

foundry, and a non-ferrous foundry which

produced metal ingots. The brass foundry closed

in 1914 in order to make space for the refining

part of the business. During the First World War

hot metal pressings were produced for shell

fuses, and the company became the first in the

country to make chilled brass bars for

stampings. After the war the firm developed a

process for hardening alloys in ingots,

including manganese copper, silicon copper,

ferro copper, and phosphor copper. In the 1950s

the product range included metal alloys for the

aircraft industry, particularly for jet engines.

In later years development continued with a

range of alloys for use in nuclear power

stations.

The factory grew to cover over 76,000 square

feet, and included an up-to-date and well

equipped research laboratory. The firm had a

large export business and sold products to

almost every country in the world. |

Another non-ferrous

foundry.

| Another of Willenhall's diverse industries

was the production of arc welding electrodes at

Invicta Electrodes Limited in Bilston Lane. The

firm, a member of the Owen Organisation,

produced a wide range of electrodes suitable for

welding mild steel, medium high tensile cast

iron, steel reinforcing, and stainless steel.

The electrodes were marketed using the trade

name "Wey", including "Speedway" and "Deepway",

and were produced on machinery built by

companies within the Owen organisation. The

factory was extended during the Second World War

to enable the firm to fulfil a number of

Government contracts which resulted in the

production of millions of feet of

electrodes. The factory had all of the latest

facilities including chemical and mechanical

laboratories, X-ray machines, and microscopy, to

ensure that the products were of the highest

quality. |

An advert from 1954.

| Although the town was dominated by factories working on metal

goods, and known for its lockmaking, there were many other manufacturers and producers of a

wide variety of products, such as those that follow: Presswork specialists W. R. R. Pedley & Company produced high

class toys, the Willenhall Box Company made cardboard boxes of

every kind, Harris & Sheldon Limited made distinctive display

fittings for shops etc., B. E. Wedge Limited galvanised all

kinds of products, H. A. Birch & Company Limited manufactured

electrical resistances, rheostats, and elements, and Grant's

Bakery produced bread and confectionery.

|

|

|

|

|

Two more

adverts from the late 1930s. |

|

| The Union Mill which stood on the corner of Union Street

and Stafford Street, was run by John Austin. He was a miller, baker,

and grocer, who became famous for something quite different.

In

1844 he introduced copper farthing tokens, which were known

as Austin Farthings. In 1853 Austin left Willenhall and moved to Allscott near Wellington, where he founded an artificial manure

works.

He sold his business in Willenhall to Joshua Rushbrooke

who had previously worked at Birchills Mill in Walsall. |

|

|

|

|

|

Both

sides of an Austin token. |

|

| Rushbrooke continued to produce the farthings which still

carried the 1844 date. Although the front remained unchanged,

the reverse side of the token now carried Rushbrooke's name. The

farthing tokens were sold to local traders at the rate of 5

shillings worth of tokens for 4 shillings and ninepence in cash. The tokens continued in circulation until 1860 when new and

smaller bronze pennies, halfpennies, and farthings were

introduced. At the same time severe penalties

were imposed on people using tokens, and so Rushbrooke

immediately called-in his tokens, which cost him a considerable

amount of money, and melted them down. He managed to sell the

copper, and completely recuperate his loss. He married the

eldest daughter of Richard Tildesley in 1849 and they had 11

children. In 1863 he retired, and went to live in Sutton

Coldfield. He was succeeded in the business by his son

Joshua. The family-run concern survived until after the Second

World War, when the building was demolished, as part of the town

centre development scheme. The Rushbrooke farthing name is still

remembered today, because the name of 'The Spring Vale Tavern' in

St. Anne's Road has been changed to 'The Rushbrooke Farthing' in

commemoration of the once well known tokens. |

|

|

|

|

Both

sides of a Rushbrooke token. |

|

|

Willenhall had its own packaging producer in the

form of the Willenhall Box Company Limited, founded in

1934 to make rigid and folding boxes for Willenhall's

lock makers and hardware trades.

The product range was extended in 1938 when a new

department was formed for the manufacture of fancy

covered boxes and shoe boxes.

In 1946 the factory was re-equipped with the latest

machinery including semi-automatic fed machines which

could efficiently produce boxes in either small or large

quantities. |

| Products included rigid, folding, collapsible, and

fancy covered boxes, cartons, and containers for almost

every trade, including boots and shoes, clothing,

electrical goods, plastics, hardware, locks, and buttons

etc. A considerable number of boxes were made for the

aircraft industry and the Ministry of Supply. The firm's

boxes were made to a high standard at an economical

price and so were extremely attractive to manufacturers

of all kinds. |

| |

|

|

| View some of the products

made in St. Anne's Road by William & H. H. James Limited |

|

|

| |

|

|

An advert from 1954.

An advert from 1865.

An advert from 1851.

An advert from 1851.

An advert from 1851.

An advert from 1954.

|

|

|

|

Two

of the many and varied industries in the

town. |

|

|

|

|

|

Adverts from

the late 1930s. |

|

|

|

|

|

More

adverts from the late 1930s. |

|

|

An advert from 1958. |

|

An advert from 1958. |

|

|

|

|

|

Return to

Religion

and Churches |

|

Return to

the contents |

|

Proceed to

Personalities |

|