|

At the beginning of the 19th century, Darlaston's

industry consisted of many

small workshops in back yards behind people's houses,

that were ideal for small family businesses

producing tools, nails, gunlocks, and gun barrels etc.

The first large factories were the ironworks that were built after the opening of the

canal, which provided an easy way of transporting heavy

items over long distances. After the Napoleonic Wars the

gun trade collapsed and so Darlaston's skilled craftsman

began to produce other products in their small

workshops. As the century progressed, the workshops

grew into small factories employing larger numbers of

people, which was possible because of the increase in

the local population. The next step forward, the

development of larger manufacturing firms happened when

the railways arrived, and brought a new form of fast and

reliable transport to much of the country, including

shipping ports such as Liverpool. By the late part of the nineteenth

century large factories had appeared, employing large

numbers of people.

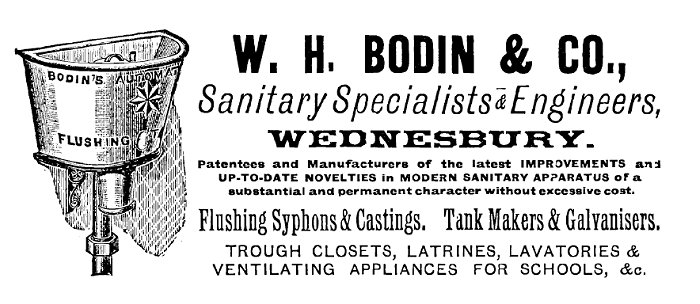

An advert from 1876.

One of the first companies in the town to have large

workshops was S & R Carter of King's Hill Works, which

was located off Birmingham Street, on a site later

occupied by Darlaston Tram Depot. |

|

|

|

|

|

| Read about S & R Carter,

King's Hill Works |

|

|

Read about the Darlaston Iron

Bridge and Roofing Company |

|

| |

|

|

|

|

| |

|

Read about some of the larger

companies: |

|

|

Charles Richards and Sons Limited |

|

|

David Etchells &

Son Limited |

|

|

Rubery Owen &

Company Limited |

|

|

Guest, Keen and

Nettlefolds |

|

|

Garringtons

Limited |

|

|

Wilkins and

Mitchell Limited |

|

|

The Steel Nut &

Joseph Hampton Limited |

|

|

The

Darlaston Bolt & Nut Company |

|

|

The Wellman Smith

Owen Engineering Corporation Limited |

|

|

E. C. & J. Keay Limited |

|

|

Samuel Platt

Limited |

|

|

F. H. Lloyd and

Company Limited |

| W. Martin Winn Limited

W. Martin Winn Ltd. opened their factory at Heath Road

in 1907. It was a family business that started by making

wrought iron nuts and bolts. They quickly realised the

advantages of steel and produced some of the first steel

nuts and bolts in Darlaston. The business quickly grew

and many of the company's products were produced from

bright drawn steel. Between 1920 and 1930 the cold

heading process was introduced which led to the

production of high tensile steel bolts. Heat treatment

was later introduced for the production of high tensile

carbon steel bolts, and alloy steel bolts. They also

produced extra large bolts weighing two or three

hundredweights each.

|

An advert from the 1920s.

| The company's founder, Mr. W. Martin Winn died in 1941.

The company was then managed by Mr. W. Norris Winn, Mrs

Martin Winn, and Mr. J. E. A. Jones. In the 1950s the firm began to produce bolts and studs

that were suitable for high temperature installations.

Large numbers of them were sold to oil refineries, and

to manufacturers of steam raising equipment.

In later

years the company benefitted from the decision to

introduce a unified thread to make British and American

screws interchangeable. Large numbers of the firm's

unified nuts and bolts were produced.

The factory closed during the

recession in the 1970s, but a small tool making

business called Winn Tools remained in the original

office building until a few years ago. Winn Tools was

founded in 1964, and survived until June 2009. |

An advert from the mid 1950s. Courtesy of

Christine and John Ashmore. |

An advert from 1960.

|

An advert from 1946. |

|

An advert from 1921. |

An advert from 1938.

An advert from 1954.

Winn Tools Limited in Kendricks Road.

Another view of the old factory.

|

An advert from 1884. |

An advert from 1908.

| |

|

Read about Wilkes Limited,

Grand Junction Works |

|

| |

|

Read about John Golcher

Limited of Bright Street,

King's Hill. |

|

| |

|

| Read about Longmore

Brothers Limited |

|

| |

|

An advert from 1908.

|

An advert from 1902 |

|

An advert from 1909. |

|

An advert from 1958. |

Wiley James & Sons Limited was established in

1860. The offices and factory were at Eagle Works,

The Green, Darlaston. The firm manufactured all

kinds of black and bright bolts & nuts, made by hand

and machine in iron or steel. Other products

included set screws, engineers' studs, coupling

boxes, builders’ roof iron work, bed screws,

handrail screws, Excelsior spout clips, horseshoe

frost studs, also Norfolk, Suffolk and other

latches.

The firm had a large export market. |

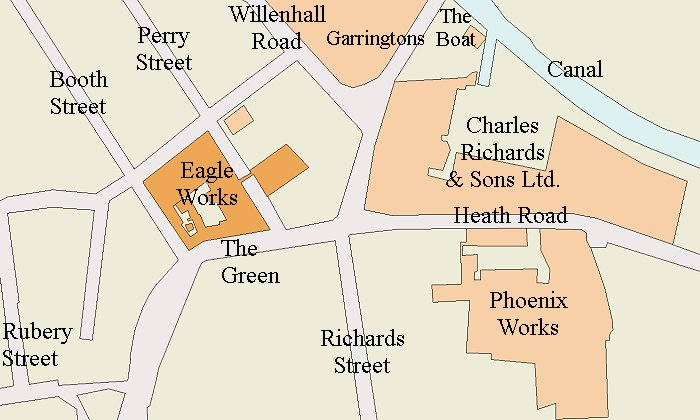

The location of Eagle Works.

The location of Eagle Works.

An advert from 1961.

|

An advert from 1954. |

An advert from 1941. |

|

|

|

|

Two

adverts from 1900. |

|

|

An advert from 1943. |

An advert from 1936. |

An advert from 1953.

The Staffordshire Bolt, Nut, and

Fencing Company's factory, London and North Western

Works, stood near Bentley Road South, in between the

Walsall Canal and the London & North Western Railway. It

was connected to the railway by a siding which also

served the nearby canal interchange goods station. The

importance of the railway to the company can be seen

from the name given to the works. This advert is from

1884. |

An advert from 1861.

|

An advert from 1865. |

Providence Works at The Green was run by Simpson

& Company, and later Simeon

Archer and Thomas Harper. The firm went into

liquidation in the autumn of 1878 and was acquired

by The Staffordshire Bolt, Nut, and Fencing Company,

which had purchased Providence Works in the mid

1870s. |

|

An advert from 1876. |

An advert from 1905. Vulcan

Foundry was at the western end of Heath Road, opposite

Charles Richards' Imperial Works. |

Partridge & Company

Sometime before 1850, Simeon Partridge, a grocer, began

to make tallow candles for sale in his shop at 28 Pinfold

Street, which he produced in a small backyard workshop. He soon opened a small factory behind Slater &

Company (solicitors) in Walsall Road, not far from the

Bull Stake. Unfortunately the building burned down in

1900 and manufacturing ceased. His son Alfred soon

opened another factory on the southern side of Heath

Road next to several old flooded mine shafts, one of

which supplied the works with water. Products included

tallow candles, yellow and carbolic soap.

The factory on the

corner of Walsall Road and Crescent Road.

From the collection of the late Howard

Madeley. |

The candles were made by repeatedly dipping candle

wicks, suspended from a frame, into molten tallow, until

the required thickness was obtained. After each dipping

the tallow was allowed to cool. One ton of tallow made

around 25,000 candles, and in a record year in the 1930s

the company made 4,000 tons of candles of various kinds.

In 1910 Gilbert Partridge took over at the works

which were sold to ESSO Limited in 1957. Within a few

years the factory closed.

The Partridge family

outside their home, Mill House, in Dorsett

Road. From the collection of the late Howard

Madeley. |

|

Read about a local pioneer

of the trade union movement |

|

| |

|

An advert from 1922.

An advert from the mid 1950s.

Chapel Street was on the site of the flats by King's

Hill Park. Courtesy of Christine and John Ashmore. |

An advert from 1861.

An advert from 1865.

| Enoch Wilkes & Company Limited of Britannia Works

was purchased by Enoch Horton &Son in the late 19th

century. It went into voluntary liquidation on 13th July, 1923.

Albert Enoch Horton was appointed as liquidator. The

factory was then taken over by G.K.N. |

| |

|

Read about the Brick

and pot makers |

|

| |

|

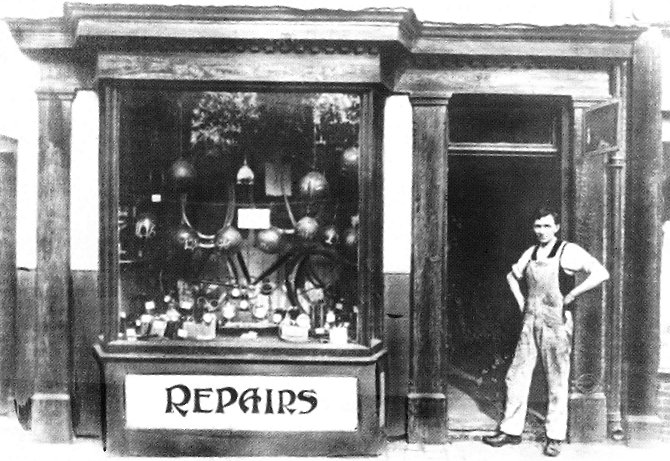

Comrade Cycles

Simeon Taylor had a shop at 76 Pinfold Street, where he

sold sports goods, and repaired bicycles at the back. He

suffered from hearing difficulties and so his wife

helped in the business. |

|

Simeon Taylor outside his

Pinfold Street shop. |

| The Taylor family lived upstairs above the shop and

had several children. Simeon built a workshop and

started to assemble bicycles. Sometime later Simeon purchased an old nut and bolt

factory on The Leys, in between Alma Street and Stafford

Road, in which to manufacture bicycles and tricycles.

The factory was previously occupied by David Harper &

Sons

It became a family business. Simeon's daughter

Florence, sons Jack and Richard, grandsons John and

Philip, and granddaughter Lynda also worked at the

factory.

They became well known for their high standard of

craftsmanship. Simeon died in 1960 after a long

illness. |

By this

time half of the company's products were exported, and

many competitors had ceased to trade because of cheap

foreign competition. Comrade went on to become the

largest independent cycle manufacturer in the country.

The company was hit by the recession in the late 1970s

and 1980s, and moved to new premises near the Bull

Stake.Unfortunately it all came to an end in 1987

because of the continuing recession, and the large

number of cheap foreign imports that flooded the market.

|

An advert from 1963. |

|

|

My late cousin Stephen Flavell,

brazing a frame at Comrade Cycles. He greatly

enjoyed working there. |

Working on Comrade cycle frames in the mid

1960s.

Brazing Comrade cycle frames in the mid

1960s.

An advert from 1896.

An advert from 1905.

An advert from the mid 1950s. Courtesy of

Christine and John Ashmore.

An advert from 1954.

An advert from the mid 1950s. Courtesy of

Christine and John Ashmore.

| |

|

| Read the story of Samuel

Rubery & Son Limited, Iron and Steel merchants |

|

| |

|

An advert from the mid 1950s. Courtesy of

Christine and John Ashmore.

|

|

|

Return to Years

of Growth |

Return to

Contents |

Proceed to

Local Government |

|